WFJ Best Cutting Type Pulverizer

WFJ Ultrafine Cutting Type Pulverizer

- Powder Size: 80-320mesh

- Capacity: 10-2000kg/h

- Motor Power (KW):13.37-119kw;

- Dimension(mm):4200*1250*2700~8500*2800*4830.

- FOB Unit Price: 1 Unit: $12,000~$48,923; 5 Units Price: 10,800~58,154.

- Application: metal, Medicine, potato, pepper, bean, grain, rice, cannabis, Sugar, herb, food, salt, mushroom, seeds, corn,

I. Characteristics and applications of cutting type pulverizers

Cutting-type pulverizers are powerful machines that are widely used in various industries for the purpose of reducing materials into smaller, more manageable particles. These pulverizers are known for their efficient cutting mechanism and versatility in handling a wide range of materials. In this article, we will explore the characteristics and applications of cutting-type pulverizers.

One of the key characteristics of cutting-type pulverizers is their ability to effectively cut through different materials, such as plastics, rubber, wood, and even metal. They employ sharp blades or knives that rotate at high speeds to slice through the material, resulting in the desired particle size reduction. The blades are typically made from hardened steel or other durable materials to ensure long-lasting performance. The cutting action of these pulverizers enables them to produce consistent and uniform particles, which is essential in many applications.

Another notable characteristic of cutting-type pulverizers is their adjustable cutting clearance. This feature allows the operator to regulate the size of the output particles by controlling the gap between the blades. By adjusting the cutting clearance, it is possible to achieve a range of particle sizes, making these pulverizers suitable for various applications. For example, finer particles may be desired for applications such as powder coatings or pharmaceutical manufacturing, while coarser particles may be needed for applications like recycling or fuel production.

Cutting-type pulverizers offer a wide range of applications across different industries. One of the primary uses is in the plastic recycling industry. These pulverizers can efficiently reduce plastic waste into smaller particles, which can then be melted down and recycled into new products. By breaking down plastic waste, cutting-type pulverizers contribute to reducing environmental pollution and promoting sustainability.

In the woodworking industry, cutting-type pulverizers are employed for the size reduction of wood waste. They can process wood scraps, sawdust, and other wood residues into smaller particles, which can be used for various purposes such as biomass fuel, animal bedding, or composite materials. The ability of these pulverizers to handle different types of wood waste makes them valuable assets in the wood processing sector.

Additionally, cutting-type pulverizers find applications in the rubber industry. They are utilized to shred rubber materials, such as tires or conveyor belts, into smaller pieces for further processing. The resulting rubber particles can be used for applications like playground surfaces, sports fields, or as a raw material for manufacturing new rubber products.

Furthermore, cutting-type pulverizers are also utilized in the metal recycling industry. They can effectively reduce metal scrap, such as aluminum, copper, or steel, into smaller sizes, facilitating the sorting and recycling process. By transforming metal waste into smaller particles, these pulverizers help conserve valuable resources and reduce the environmental impact of metal extraction and production.

In conclusion, cutting-type pulverizers possess several characteristics that make them highly versatile and efficient machines for particle size reduction. Their ability to cut through various materials, adjustable cutting clearance, and consistent particle size output make them suitable for a wide range of applications. From plastic recycling to wood processing, rubber shredding to metal recycling, cutting-type pulverizers play a crucial role in various industries, contributing to waste reduction, resource conservation, and sustainable manufacturing practices.

Performance evaluation and optimization of cutting type pulverizers

Performance evaluation and optimization are crucial aspects in the operation of cutting-type pulverizers. These processes involve assessing the efficiency, productivity, and output quality of the pulverizers and implementing measures to enhance their performance. In this article, we will explore the significance of performance evaluation and optimization in cutting-type pulverizers and the techniques used for achieving optimal results.

Performance evaluation of cutting-type pulverizers involves measuring key parameters to determine their effectiveness in particle size reduction. One of the primary performance metrics is the throughput, which refers to the amount of material processed by the pulverizer within a given time frame. By measuring the throughput, operators can assess the productivity of the pulverizer and identify potential bottlenecks or inefficiencies in the system.

Another important parameter for performance evaluation is the particle size distribution of the output material. A consistent and uniform particle size is often desired for many applications. Evaluating the particle size distribution helps in determining whether the pulverizer is achieving the desired results. Techniques such as sieving or laser diffraction analysis can be employed to assess the particle size distribution and make adjustments if necessary.

In addition to evaluating performance, optimization techniques are employed to enhance the efficiency and output quality of cutting-type pulverizers. One common optimization approach is adjusting the cutting clearance. By optimizing the gap between the blades, operators can control the particle size produced by the pulverizer. Fine-tuning the cutting clearance based on the desired particle size can result in improved efficiency and quality of the output material.

Another optimization technique is blade selection and maintenance. Choosing the right type of blades based on the material being processed can significantly impact the performance of the pulverizer. Blades with different profiles, angles, or materials may be required for specific applications. Additionally, regular inspection and maintenance of the blades are essential to ensure sharpness and prevent any damage or wear that could affect the pulverizer’s performance.

Furthermore, optimizing the feeding system is crucial for maximizing the performance of cutting-type pulverizers. Proper feeding techniques, such as controlling the feed rate and ensuring a consistent material flow, can prevent overloading or underutilization of the pulverizer. Uneven or erratic feeding can lead to inefficiencies and inconsistent output quality. Employing techniques such as feeders or conveyor systems can help achieve optimal feeding conditions.

Moreover, monitoring and controlling the operating parameters of cutting-type pulverizers play a significant role in performance optimization. Parameters such as rotational speed, temperature, and pressure can impact the efficiency and output quality. Implementing advanced control systems and sensors can enable real-time monitoring and adjustment of these parameters, ensuring optimal operation of the pulverizer.

In conclusion, performance evaluation and optimization are vital for achieving efficient and high-quality operation of cutting-type pulverizers. Evaluating parameters such as throughput and particle size distribution provides insights into the effectiveness of the pulverizer. Optimization techniques, such as adjusting the cutting clearance, blade selection and maintenance, optimizing the feeding system, and monitoring operating parameters, help enhance the performance and output quality. By continually evaluating and optimizing the performance of cutting-type pulverizers, operators can maximize efficiency, productivity, and the overall effectiveness of these machines in particle size reduction processes.

Parameter of Cutting Type Pulverizer:

| Model | WFJ-15 |

| Working Volume | 10-100 |

| Capacity(kg/h) | 2-2.5 |

| Fineness(Mesh) | 200-1800 |

| Cooling Form | Liquid Cooling(Chiller) |

| Power(KW) | 1.5 |

| Weight(KG) | 580 |

| Dimension(L*W*H) | 1200*800*1400 |

| Business Type: | Manufacturer/Factory | Main Products: | Mill, grinder, granulator, mixer, Crushing Equipment |

| Number of Employees: | 100 | Year of Establishment: | 2014.05 |

| Production Capacity | 5000Set/Year | After-sales Service: | Technical Support; on-line teach lessons |

| R&D Capacity: | ODM, OEM | Annual Output Value: | US$5 Million – US$10 Million |

| No. of R&D Staff: | 5 | No. of Production Lines: | 6 |

LK Mixer is a professional manufacturer for grinder, mixer and pulverizer. These machines are widely used in pharmaceutical, cosmetic, health care products and chemical industries. Our main product including granulating machine, grinder, mixer, dryer, etc. All mechanical products in accordance with the China GMP design requirements. And also we have other certifications such as CE, UL for motors.

Business Philosophy

“Quality is the main policy of sales” and “integrity is the principle of success” are the business philosophy of our people. We carry out one-year warranty, lifelong maintenance service, with technical consultation, with material test machine and other services, and long-term supply of equipment. Welcome new and old customers to negotiate cooperation!

Certifications:

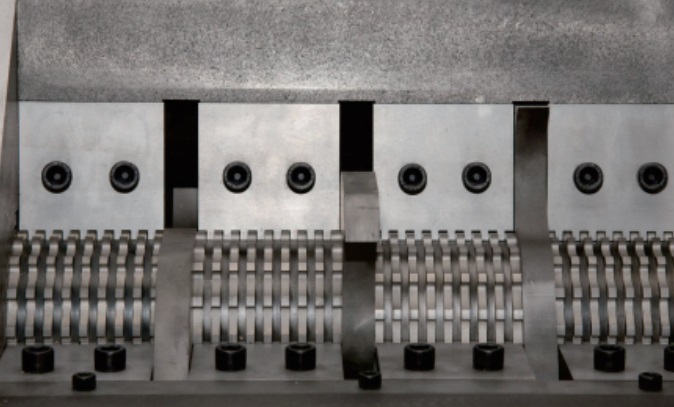

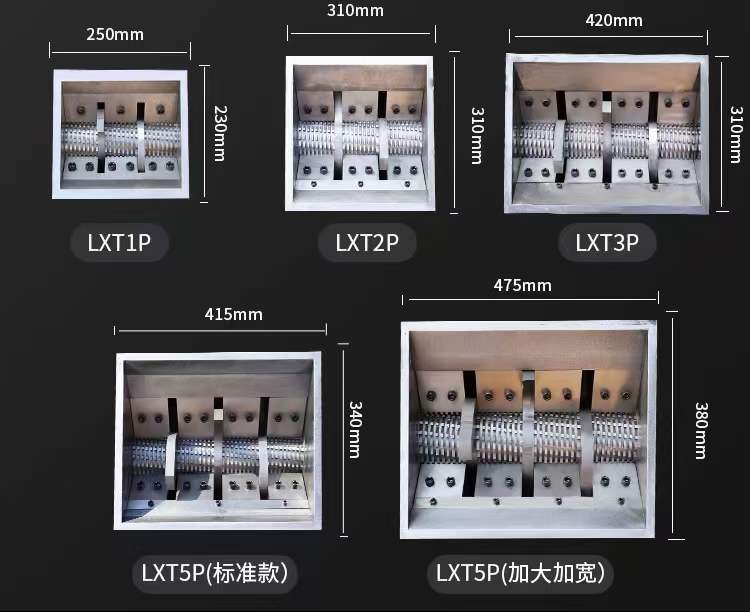

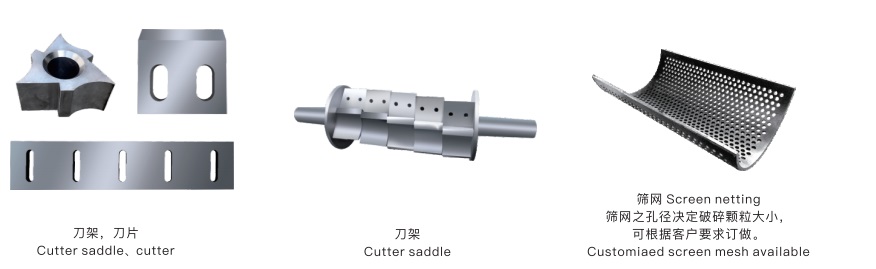

Various Cutting Knife Type Pictures:

Electric Cabinet with UL Certification

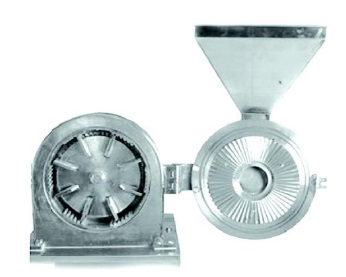

Cyclone Processor and Motors:

Spare Parts:

Small Machine Packing:

Small machine packed with export fumigation-free wooden cases, goes with bulk shipment or in container.

When packing small machines for sea shipment, it is important to take measures to ensure that the machines are protected from damage during transit. Here are some general steps that a manufacturer may follow when packing small machines for sea shipment:

- Clean and dry the machine: Before packing, the machine should be thoroughly cleaned and dried to prevent any moisture or debris from causing damage during transit.

- Disassemble the machine: If possible, the machine should be disassembled into its component parts to reduce its overall size and make it easier to pack.

- Wrap the machine in protective material: The machine should be wrapped in a layer of protective material, such as bubble wrap or foam, to protect it from scratches and impact during transit.

- Place the machine in a sturdy box: The wrapped machine should then be placed in a sturdy box that is appropriate for the size and weight of the machine. The box should be made of durable material, such as corrugated cardboard or plywood, and should be able to withstand the rigors of sea transit.

- Add packing material: The box should be filled with packing material, such as packing peanuts or air pillows, to provide cushioning and prevent the machine from shifting during transit.

- Seal the box: The box should be securely sealed with high-quality packing tape to prevent it from opening during transit.

- Label the box: The box should be clearly labeled with the machine’s name, weight, and any other relevant information, as well as the destination address and contact information.

Overall, the goal is to pack the small machine in a way that will protect it from damage during transit and ensure that it arrives at its destination in good condition. It is important to follow proper packing procedures and use high-quality packing materials to minimize the risk of damage during sea shipment.

Large Machine Packing:

Packing a large machine for sea shipment can be a complex and challenging task. However, with careful planning and attention to detail, it is possible to pack a large machine for sea shipment in a way that will ensure that it arrives at its destination in good condition. Here are some general steps that a manufacturer may follow when packing up a large machine for sea shipment:

- Clean and prepare the machine: Before packing, the machine should be thoroughly cleaned and prepared. All fluids, such as oil or coolant, should be drained, and any loose or detachable parts should be removed.

- Disassemble the machine: If possible, the machine should be disassembled into its component parts to reduce its overall size and make it easier to pack. Each part should be carefully labeled and numbered to ensure that it can be easily reassembled at the destination.

- Protect delicate parts: Delicate or fragile parts should be wrapped in protective material, such as bubble wrap or foam, to protect them from damage during transit.

- Build a custom crate: A custom crate should be built around the machine to provide a secure and sturdy enclosure. The crate should be made of durable material, such as plywood, and should be designed to fit the machine snugly. The crate should also include braces or supports to prevent the machine from shifting during transit.

- Add cushioning material: The crate should be filled with cushioning material, such as packing peanuts or air pillows, to provide extra protection and prevent the machine from moving or shifting during transit.

- Securely fasten the machine: The machine should be securely fastened to the crate to prevent it from moving or shifting during transit. This may involve using straps, bolts, or other fasteners to hold the machine in place.

- Seal and label the crate: The crate should be securely sealed with high-quality packing tape, and should be clearly labeled with the machine’s name, weight, and any other relevant information. The destination address and contact information should also be clearly marked on the crate.

Overall, packing a large machine for sea shipment requires careful planning and attention to detail. It is important to use high-quality materials and follow proper packing procedures to ensure that the machine arrives at its destination in good condition. A professional packing and shipping company may be consulted to ensure that the machine is properly packed and prepared for sea shipment.

Customer Side Machine Groups Showcase Videos:

Dust Collector Shipment

Shipment – Packing Method

Two Large Industrial Grinder Ready to Ship

Domestic Shipment Show Case:

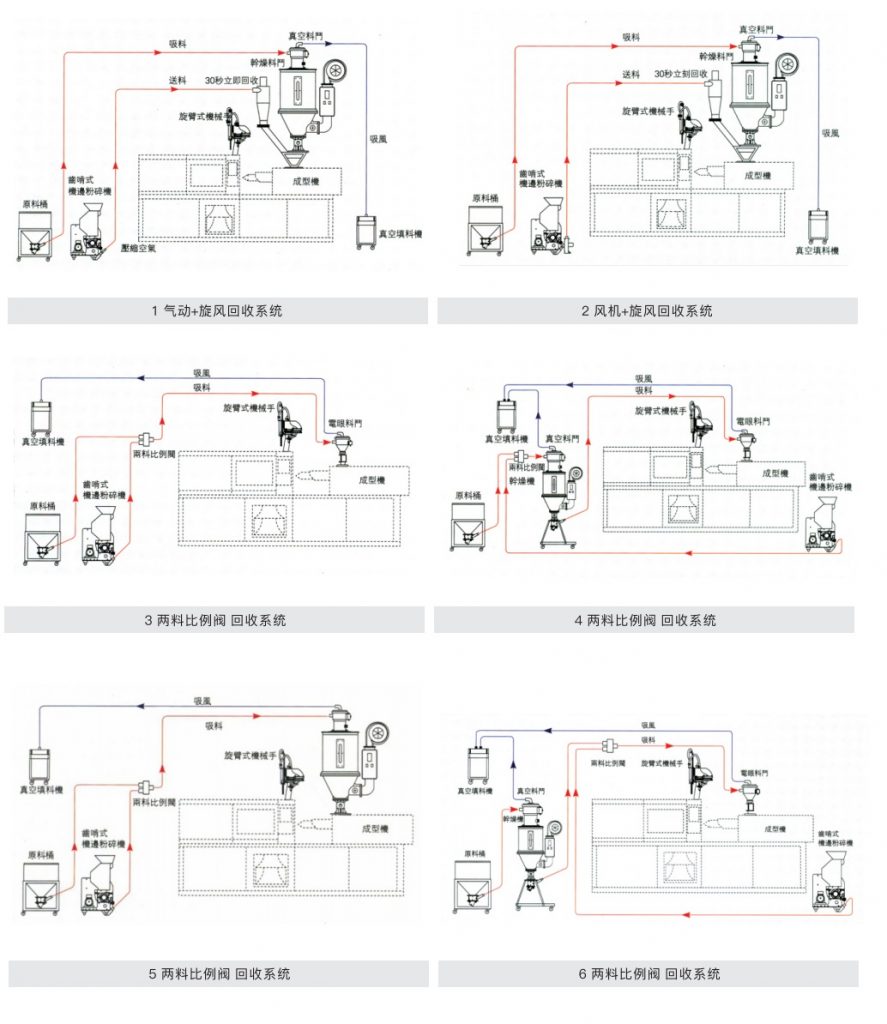

Installation Layout:

Maintenance and Safety Measures

Proper maintenance practices for the machine

Proper maintenance practices are essential for ensuring the efficient and safe operation of a universal grinder. Here are some maintenance practices that should be followed:

- Regular cleaning – The machine should be cleaned regularly to remove any debris, dust, or coolant that may accumulate on the machine’s surfaces. This can be done using a soft brush, air hose, or a cleaning solution.

- Lubrication – The machine’s moving parts should be lubricated regularly to reduce friction and wear. The manufacturer’s recommendations for lubrication intervals and types should be followed.

- Inspection – The machine should be inspected regularly for any signs of wear, damage, or misalignment. Any issues should be addressed immediately to prevent further damage or safety hazards.

- Replacement of worn or damaged parts – Worn or damaged parts should be replaced immediately with genuine parts from the manufacturer.

- Calibration – The machine should be calibrated regularly to ensure that it is operating within the specified tolerances and accuracy.

- Operator training – Proper operator training is essential for ensuring the safe and efficient operation of the machine. Operators should be trained on the proper operation, maintenance, and safety procedures for the machine.

- Record keeping – A maintenance log should be kept to track the machine’s maintenance history, including cleaning, lubrication, inspection, and repairs. This can help identify any trends or issues that need to be addressed.

Following these maintenance practices can help ensure the safe and efficient operation of a universal grinder, prolong its lifespan, and reduce the risk of downtime and costly repairs.

Safety measures for operators and workers

Safety measures for operators and workers are crucial when using a universal grinder. Here are some safety measures that should be followed:

- Personal protective equipment (PPE) – Operators and workers should wear appropriate PPE, including safety glasses, hearing protection, gloves, and safety shoes.

- Machine guards – The machine should be equipped with proper machine guards to prevent access to the grinding wheel during operation. The guards should be in good condition and properly installed.

- Lockout/tagout procedures – Lockout/tagout procedures should be followed to ensure that the machine is not accidentally started or energized during maintenance or repair.

- Training – Operators and workers should receive proper training on the safe operation of the machine, including the use of PPE, machine guards, and lockout/tagout procedures.

- Inspection – The machine should be inspected regularly for any signs of wear, damage, or misalignment that may pose a safety hazard.

- Proper use of grinding wheels – Operators should ensure that the grinding wheel is properly installed, dressed, and aligned. The grinding wheel should not be overloaded or forced into the material being ground.

- Proper handling of coolant – If coolant is used, operators should ensure that it is properly mixed, applied, and contained. Coolant should not be allowed to accumulate on the floor, as it can create a slipping hazard.

- Emergency procedures – Emergency procedures should be established and communicated to all operators and workers in case of an accident or injury.

Following these safety measures can help prevent accidents and injuries when using a universal grinder. It is important to prioritize safety and ensure that all operators and workers are trained and informed about the potential hazards of the machine.

About LKMixer

LKMixer is a professional manufacturer for fertilizer production line, grinder, mixer and granulator, shredder. These machines are widely used in food, pharmaceutical, cosmetic, health care products and chemical industries. The Food materials like Peanut, mushroom, seeds, potato, bean, tobacco, salt, cannabis, tea, Sugar, corn, Coffee, rice, pepper, grain as so on. Grinders have many types such as Pulse Dust Grinder which suitable for zero pollution environment, Turbine Mill which is suitable for coffee bean, 12-120mesh all can meet, Ultrafine Grinding Mill covers 80-200mesh, and also Winnowing Dust Grinder or other grinding machines like SF Hammer. Welcome to contact us for details. Contact us for more information. Proposal, catalog, quotation. Mobile/WhatsApp: +86 18019763531 Tel: +86 21 66037855 Email: sales@lkmixer.com

Contact Us

Cutting Type Powder Grinding Mill Youtube Video (See More)

FAQ(Click and See More)

What is the difference between a pulverizer and a hammer mill?

Pulverizers and hammer mills are two common machines used for particle size reduction in various industries. While they share similarities in their function of reducing materials, there are distinct differences between the two. In this article, we will explore the dissimilarities between pulverizers and hammer mills.

A pulverizer, also known as a grinder or mill, is a mechanical device used for the purpose of grinding, crushing, or pulverizing different types of materials into smaller particles. Pulverizers typically consist of a rotating drum or cylinder, which contains grinding media such as steel balls or rods. The material to be pulverized is fed into the drum, and as the drum rotates, the grinding media crush and grind the material, resulting in size reduction.

On the other hand, a hammer mill is a machine that uses a series of rotating hammers or blades to crush or shred materials into smaller pieces. Hammer mills operate by the principle of impact, where the hammers strike the material and break it apart. The material is fed into the hammer mill chamber, and the rotating hammers or blades apply force to the material, reducing it to the desired particle size.

One significant difference between pulverizers and hammer mills lies in the mechanism of particle size reduction. Pulverizers primarily use the forces of compression, impact, and attrition to reduce the size of materials. The grinding media within the pulverizer drum collide with the material, exerting pressure and causing fractures and attrition. The resulting particles are typically finer and more uniform in size.

In contrast, hammer mills rely on the principle of impact to break down materials. The high-speed rotating hammers or blades strike the material with force, causing it to fracture and break apart. The impact forces generated by the hammers result in a range of particle sizes, from fine to coarse, depending on the size of the screen or grate used in the mill.

Another notable difference between pulverizers and hammer mills is the range of materials they can process. Pulverizers are versatile machines that can handle a wide variety of materials, including minerals, chemicals, plastics, and food products. They are commonly used in industries such as mining, pharmaceuticals, and food processing. In contrast, hammer mills are primarily used for processing agricultural and organic materials, such as grains, wood, and biomass. They find applications in industries such as agriculture, animal feed production, and wood processing.

Furthermore, the operating speed and energy consumption differ between pulverizers and hammer mills. Pulverizers typically operate at higher speeds compared to hammer mills, resulting in higher energy consumption. The high-speed rotation of the pulverizer drum requires more power to drive the grinding media and achieve size reduction. In contrast, hammer mills generally operate at lower speeds, requiring less energy for operation.

In conclusion, although both pulverizers and hammer mills are used for particle size reduction, they differ in their mechanisms, range of materials they can process, and operating characteristics. Pulverizers primarily use compression, impact, and attrition forces, while hammer mills rely on impact forces. Pulverizers are versatile machines used in various industries, while hammer mills are primarily employed in agriculture and wood processing. Understanding the differences between these two machines is crucial in selecting the appropriate equipment for specific applications.