How does a pulverizer work?

What is a pulverizer(pulveriser)?

A pulverizer is a large machine used to break hard and larger things into small pieces. In this article, we will learn how the pulverizer grinds food into fine powder and learn about its uses in different industries. The pulverizer is not only used for one substance, it can process a wide variety of raw materials.

Shredders provide different services for different customers, such as turning medicine into powder, turning wood into pulp, grinding grain into powder for food production, and can also be used to dispose of used tires, break down building materials, soil treatment, disposal of abandoned vehicles, and so on.

Some industries that rely on shredders include construction, agriculture, industrial manufacturing, power generation, medicine, horticulture, laboratories, printing, recycling, and material processing.

How does the pulverizer work?

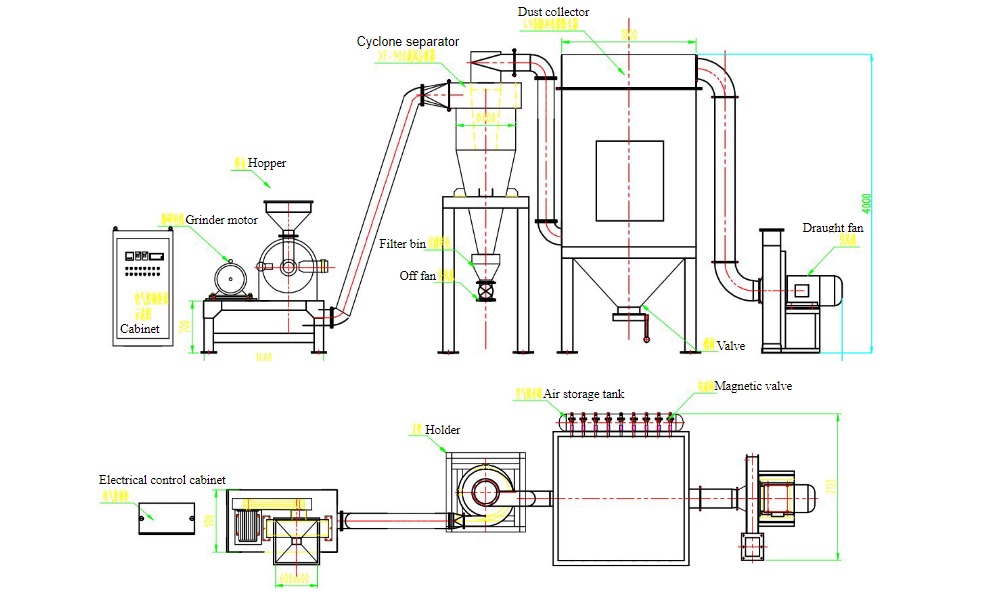

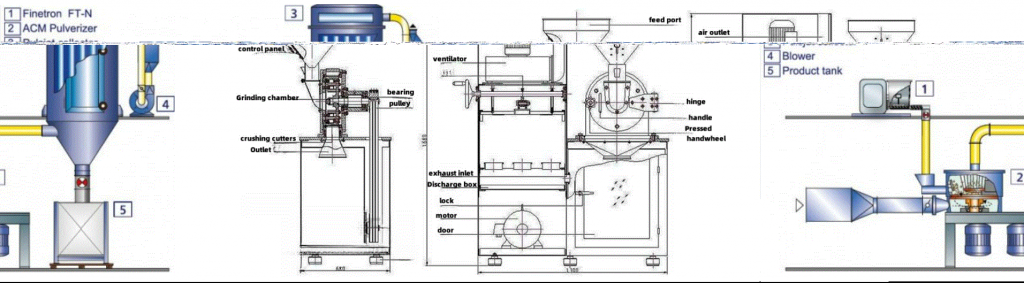

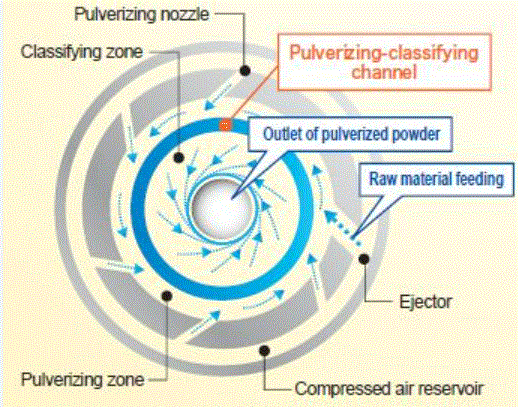

When the mill is working, the main motor first drives the spindle and the turntable to rotate through the reducer. The bulk material is processed by the hammer pulverizer and broken into small particles, which are then sent to the storage bin by the elevator. Next, the material is evenly delivered to the bulk tray on the upper part of the turntable through a vibrating feeder and inclined feed pipe. Under the action of centrifugal force, the material is dispersed around the circumference, falls into the grinding ring raceway, and is impacted, rolled and ground by the ring roller. After three layers of raceway processing, the material becomes powder. Finally, the high-pressure fan draws the outside air into the machine by suction, and brings the broken material into the separator.

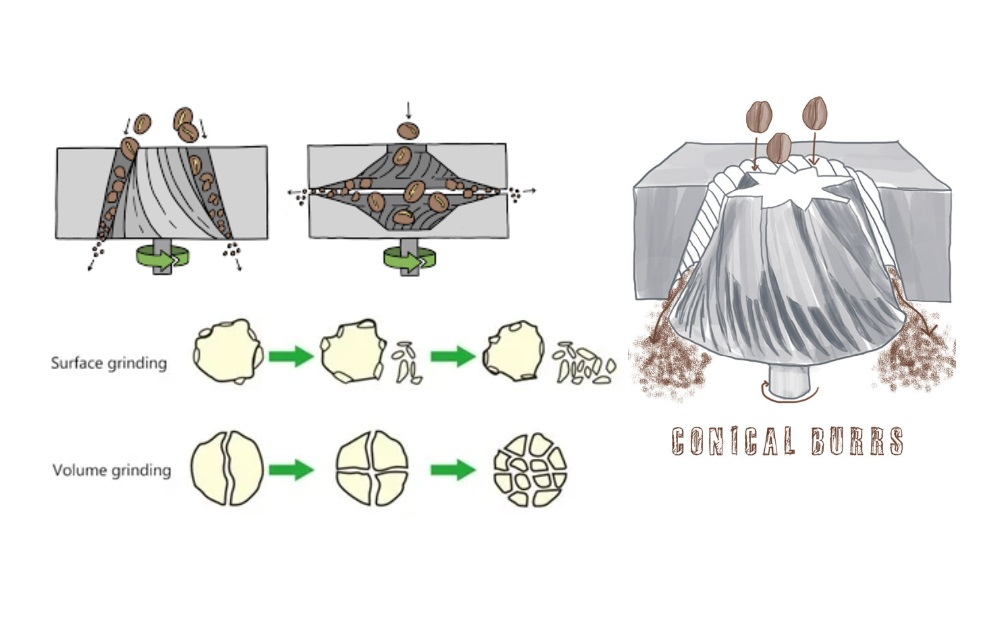

Pulverizers use extrusion and impact to process materials, which are created by pressure and collision forces. Grinders use friction to break down materials. Friction in grinders is caused by grinding media, which can be a variety of different materials, such as non-spark lead, ceramics, brass, bronze, and flint.

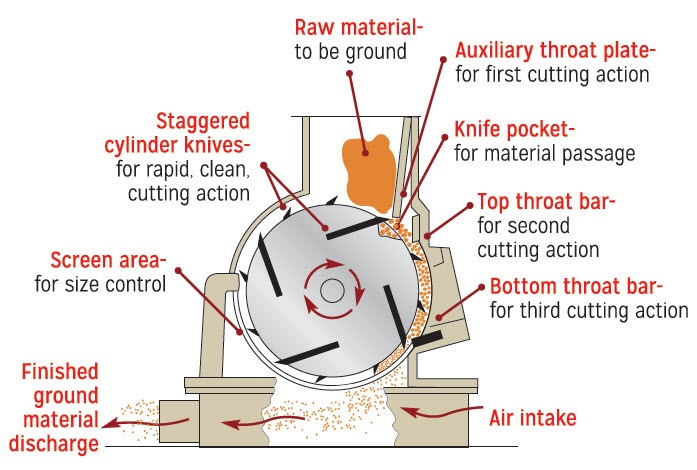

The two common grinding machines are the ball mill and the hammer mill. A ball mill consists of a horizontally mounted rotating cylinder using a grinding medium such as a steel ball or steel rod. A hammer mill, on the other hand, uses a number of hammers mounted in steel that rotate rapidly in a vertical plane.

Shredders process the material in batches or continuously by taking in the incoming material (usually on a conveyor belt), rotating it and pressing the broken material into it, and then sending it out. They can also cool, heat or inflate the material as it leaves. For user convenience, the pulverizer can crush the material to different fineness levels, from very fine to coarse.

The working principle of the mill is quite complex, but understanding its basic mechanism is very important for us. These machines are usually made of strong stainless steel to prevent rust and protect the machine and materials. An electric motor inside the machine enables grinding operations and ensures that no residue is left behind.

Types of pulverizer

The pulverizer can generally be divided into three types: crusher, impact machine and grinding machine. The pulverizercompresses large pieces of material such as rocks and stones into small pieces that become gravel or dust. They are often used to reduce the size of materials, facilitate the handling or recycling of materials, and simplify the sorting of materials.

One of the most common pulverizer designs is the jaw crusher, which has two jaws, one fixed and one removable. An impact pulverizers very similar to a crusher, but it reduces the size of the material by impact force rather than by extrusion.

Pulverizers for Sale:

In addition, the pulverizer can also be classified according to its working principle. A grinder uses friction to break up materials. The grinding media can be a variety of different materials, such as brass, bronze, ceramics, flint, and non-spark lead. Common grinding machines are hammer grinding machines and ball mills.

Hammer grinders are mainly used on farms and use steel or stainless steel wrapped hammers to grind husks and grains.

Another common type of mill is the ball mill, which uses steel rods, balls, or similar media to grind the material. The ball mill is simple in structure and consists of a horizontally mounted rotating cylinder and a lining. The user would put the medium into the cylinder and then toss or roll it.

There is also a tube mill, which is similar to a ball mill, and sometimes people confuse them. Tube mills also consist of rotating cylinders and linings, but they are usually larger and use a mixture of water and media for fine grinding. The medium enters at one end and exits as a slurry at the other.

The use of pulverizer in food industry

In the food industry, there are many different types of pulverizer, which are responsible for different tasks. For example, you can’t grind wheat, rice, corn, or millet in a grinder used for coriander, cloves, or cinnamon. Different shredders have different functions.

Ingredients usually need to be crushed or crushed before they can be used in food preparation. That’s what the pulverizer is for. But the question is what type of pulverizer does the food industry use? In fact, the types used vary.

Generally speaking, one type of pulverizer is used for grinding the main ingredients such as wheat, rice, corn and millet, and the other is used for grinding spices such as coriander, cloves, turmeric and pepper, which are used in small quantities.

Let’s take an example to understand. For example, if a person named “X” wants to make pancakes and vegetables, and he has raw wheat and spices on hand. X needed two different crushers, one for grinding wheat and the other for grinding spices. Although the purpose of the work is similar, the way of working is slightly different.

The working intensity of each type of crusher is different, and the electricity and power required are also different. Some require more, some less, depending on the quality and nature of the raw material. The fundamentals of operating a wheat or spice crusher require a lot of knowledge.

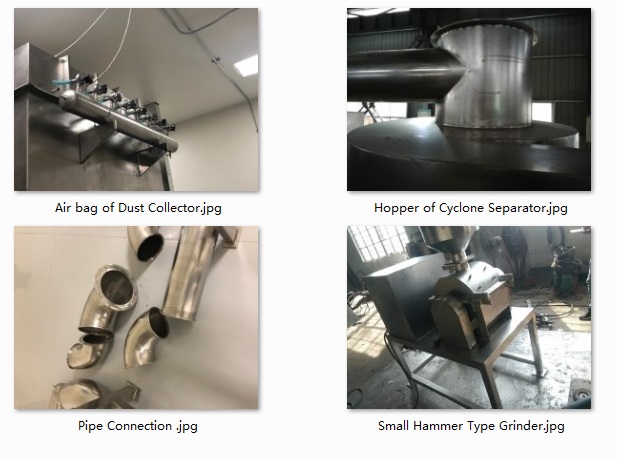

About LKMixer

LKMixer is a professional manufacturer for fertilizer production line, grinder, mixer and granulator, shredder. These machines are widely used in food, pharmaceutical, cosmetic, health care products and chemical industries. The Food materials like Peanut, mushroom, seeds, potato, bean, tobacco, salt, cannabis, tea, Sugar, corn, Coffee, rice, pepper, grain as so on. Grinders have many types such as Pulse Dust Grinder which suitable for zero pollution environment, Turbine Mill which is suitable for coffee bean, 12-120mesh all can meet, Ultrafine Grinding Mill covers 80-200mesh, and also Winnowing Dust Grinder or other grinding machines like SF Hammer. Welcome to contact us for details.

What is the cost of using the pulverizer?

As mentioned above, there are different types of pulverizer, the cost of which depends on quality and functionality. Here are the prices of different types of crusher:

- The price of the automatic cold pulverizer is about 50,000 to 60,000 yuan.

- Some spice pulverizer cost around 30,000 yuan.

- The price of the wheat pulverizer is between 70,000 and 80,000 yuan, and the quality is good.

- In order to make the gravy of dishes more thick, the price of food gravy pulverizer is between 100,000 and 300,000 yuan.

- Depending on the ingredients and needs you are dealing with, you can choose the crusher that is right for you.

In general, learning to use these machines is not very difficult, and they are not very expensive. Investing in these machines might be a good idea.