How to Use Blender?

As a common industrial equipment, the Blender is a machine that uses mechanical force and gravity to evenly mix two or more kinds of materials. Blender machinery is widely used in various industrial daily life. It is widely used in the mixing, mixing and homogenization of various materials. The Blender can combine a variety of materials into a uniform mixture, such as mixing cement, sand, gravel and water into wet concrete, etc. It can also increase the contact surface area of the material to promote chemical reactions; It can also accelerate physical changes, such as the addition of granular solutes to solvents, which can accelerate the dissolution and mixing through the role of mixing machinery. When operating the Blender, we need to follow certain steps and precautions to ensure the normal operation of the equipment and the high-quality mixing of the materials.

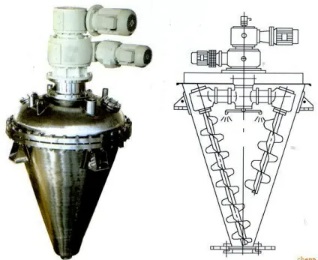

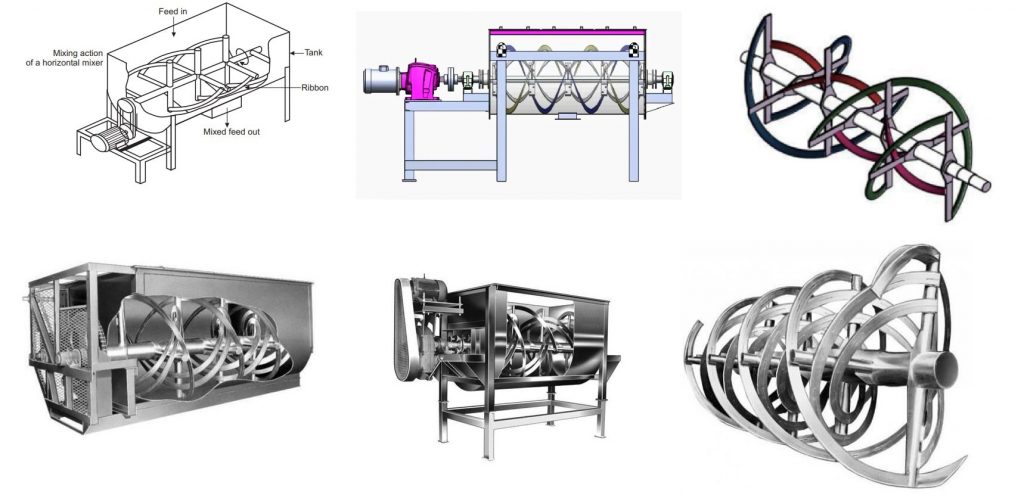

Commonly used mixers are divided into four categories: gas and low viscosity liquid mixers, medium and high viscosity liquid and paste mixing machinery, thermoplastic material mixers, powder and granular solid material mixing machinery.

How to use Blender? Before start to blending, we need to understand and confirm the following 13 items:

- Confirm the model and working mode of the mixer, and operate according to the instructions.

- Clean the mixer, for a long time not used or previously mixed materials are different, need to clean the mixer to ensure the quality and safety of the mixture when using the mixer next time;

- Prepare the mixing materials, select the materials to be mixed according to the actual requirements, and mix the materials according to the ratio requirements. Clean the machine and workplace, check whether the dust collection system is normal;

- Check whether the glue in the glue can is clean enough. When insufficient, add glue appropriately according to dosage;

- Adjust the position of the balance rod according to the length and width of the work-piece;

- According to the thickness of the workpiece, adjust the distance between the upper yazhou and the lower orbit to ensure that the workpiece is pressed stably and will not crush the workpiece surface because of too tight;

- Adjust the size of the rubber door so that the edge sealing material can be uniformly and fully bonded;

- Through debugging, see whether the mixer works normally;

- Prepare materials and accessories (substrate, paper, etc.) .

Materials containing less than 5% in the formula and materials with poor fluency must be premixed for 15 minutes; When premixed, the ratio of premixed material to carrier is 1:(51, ~10); - After premixing, add other main raw materials and starch, etc., continue mixing for about 15 minutes;

- When mixing food additives that do not need to be premixed, the mixing time is set to 20 minutes:

- Test the mixing uniformity regularly to determine the best mixing time;

- Add gear oil to the reducer regularly and replace the gear oil

- Pay attention to the items before using the mixer:the first running empty car before the work, the body should be stable, no more than normal vibration, and observe whether the discharge mechanism is normal; Start the deceleration motor first during the work, and feed it after the rotor rotates normally. It is strictly forbidden to feed and start it again; the machine feed material should not be lower than the horizontal axis; small materials in the main material input at the same time, grease and other liquids in the main material all into the machine and then spray into; the material can not be mixed with metal debris, so as not to affect the rotation or damage the blade; In case of failure, first release the material, stop the matching, and carry out maintenance; this work by the microcomputer and small material workers responsible; Mixer is a large mechanical tool, please pay attention to safety in the use of the process, individual hidden dangers appear, you can refer to the above mentioned attention items, standardized operation can effectively improve work efficiency, and harvest the corresponding benefits, the above summarizes the mixer related information and applicable methods and attention items, hope to be helpful to users.

Start mixing:

After Mixing, what you need to do?

- Stop the mixer and turn off the power.

- Pour out the mixed materials in the mixer and carry out necessary treatment.

- Thoroughly clean the mixer and store the mixer in a safe and dry place.

Summary: From the preparation work to the start-up of the mixer to the cleaning of the mixture, these steps require strict compliance with the operating procedures to ensure the quality and safety of the mixture. The use of the mixer is not difficult, only in the correct understanding of the mixer and strict compliance with the operating procedures of the premise, in order to achieve the best mixing effect.

About LKMixer

LKMixer is a professional manufacturer for fertilizer production line, grinder, mixer and granulator, shredder. These machines are widely used in food, pharmaceutical, cosmetic, health care products and chemical industries. The Food materials like Peanut, mushroom, seeds, potato, bean, tobacco, salt, cannabis, tea, Sugar, corn, Coffee, rice, pepper, grain as so on. Grinders have many types such as Pulse Dust Grinder which suitable for zero pollution environment, Turbine Mill which is suitable for coffee bean, 12-120mesh all can meet, Ultrafine Grinding Mill covers 80-200mesh, and also Winnowing Dust Grinder or other grinding machines like SF Hammer. Welcome to contact us for details. Contact us for more information. Proposal, catalog, quotation. Mobile/WhatsApp: +86 18019763531 Tel: +86 21 66037855 Email: sales@lkmixer.com

Contact Us

How to Use V Blender

The structure and principle of V-type mixer, how to use V-type mixer correctly and save a lot of costs

In the daily mixing production process, the mixer is generally used, there are two-dimensional mixers, three-dimensional mixers, and double-cone mixers and V-type mixers, so what is the structure and principle of the V-type mixer, and how to correctly operate and use the V-type mixer is a key step.

The V-type mixer, as the name suggests, has a V-shaped structure of the mixing barrel, where the material is poured into the feed port at both ends and discharged from the bottom discharge valve after reversing the mixing.

The interior can generally be designed with mixing blades and forced circulation mixing system, and some customers can also increase the spray automation system.

General equipment needs to be completely grounded, so as to ensure the safety of use, and when loading materials, it does not mean that it must be filled, or it can be mixed to complete, so generally we will have a certain loading factor, generally this loading factor will be controlled at about 50%. In this way, the mixing time can be shortened or the efficiency can be improved a lot.

Blender Videos

You may also interest in:

FAQ(Click and See More)

Why Choose Us?

We have 20 years manufacturing experiences; 15600 cubic meters factory area; 5000sets annual capacity; 55 professional engineers;

What’s your main maket?

South America: Brazil, Colombia, Peru, Bolivia, Uruguay, Paraguay ;Romania;

USA with UL Certification

Middle East: Saudi, Arabia, Oman, Turkey

Europe: Russia, Australia, Belarus, Ukraine, Poland

Can you support OEM?

– Yes, OEM or ODM. Machine can be customized according to customer detail requirement, including capacity and voltages, motor certifications.

– Drawing and raw materials also can be customized.

What after-sale services?

– 7*24 customer service online;

– 7*24 engineers online services;

– 12 months warranty services.

WHAT kind of MACHINE YOUR COMPANY HAVE?

CAN YOU GIVE ME GUIDE ON OTHER MACHINE ? TO FULL MY PRODUCTION LINE

YES ! Our f have factory build more than 20 years now, we can design and customize whole line, besides of the grinding machine, mixing machine, we can also fully support to provide the washing machine, cutting machine, drying machine, packing machine, filling machine. Though we are not producing these machine, but our brother companies co-work together for over 20 years, we have rich experience in providing you a full effective production line, fully automatically or semi-automatically.

HOW TO VISIT YOUR COMPANY?

Our Factory located in Jiangsu Province, very near to Shanghai, you can fly to Shanghai Pudong Airport, we pick you up and take you by car 2 hours ride, can reach our factory, welcome your visit.

WHAT’S YOUR BEFORE & AFTER SERVICE ?

1) Before your purchasing, we need to know your detail request, such as what kind of material you want to grind and mixing, what final product powder or granule you want to reach. Because different material and powder sizes request of different machine to do. We can provide professional advice and rich experience help to choose machine. Most of the products we have already did before for other customer, trail test or run mass production, so we knows which machine is best in performance of grinding and mixing. This is of very importance in helping you choose the right model. We also wish this can help our customer a lot. Even the material we didn’t do before, we will prepare the same material and to do the trail test and send video to you for your reference.

2) One Year guarantee of machine quality. If the machine have problem within one year, we will send you the spare parts to you for replacement, but this not including the damage caused by human causes. We also have 24 hours on line guide for customer, if you have operation difficulty, we will guide by video and on line communication with our engineer for your emergency debug.

3) For small machine, we sell with whole machine, it’s no need to install, and easy to operation, no problems for operation. While for large machine, its’s also not difficult to install with video guideline, but if you need, we can assign our technicians to go abroad, the round ticket, food and residents will be paid by customer.

HOW ABOUT YOUR PAYMENT TERM?

Our payment term is T/T. 50% payment in advance, rest of 50% payment finish before the goods shipped. When we finish the machine production we will do trail test and run the machine take videos for your green light. You pay the rest of 50% payment then.