Hot Air Oven

- Material: Powder or dry granule, thermal sensitive, easy oxidation material ;

- Volume: 100~5000L;

- Total Power: 0.75~15KW;

- Application: Pharmaceuticals, Nutraceuticals, Food Products, Chemicals, Fertilizer, Stucco, Clay, Potting Soils.

- Notice: This is just an example. Please contact with our sales for choosing the right model.

- Price: $805~15,300.

What is a Hot Air Oven?

The air blower is equipped with an automatic thermostat control system. There are also computer control systems available as options, which can increase thermal efficiency by up to about 20%. The system utilizes steam or electricity as a heat source and includes an air blower and heat exchanger for effective heat distribution.

Hot air flows through the baking chamber, transmitting heat to the supplies. Fresh air is introduced into the system to remove damp and hot air, which is discharged through vents. This maintains the proper relative humidity inside the oven. The main advantage of these ovens is the circulation of hot air within a closed system, which enhances heat transfer and saves energy.

These ovens are versatile and suitable for a wide range of applications, such as pharmacy, chemical industry, food, light industry, and manufacturing. They are used for heating, solidifying, drying, and dehydrating various products, including raw materials, medicinal herbs, powders, particles, aqueous medicines, various honeys, packaging bottles, pigments, dyes, dehydrated vegetables, fruits, sausages, plastic resins, electrical components, and baked goods.

Horizontal wind: Horizontal wind is left out of the air, right suction, suitable for powder items baking!

Vertical wind: Vertical wind is the air on both sides, the middle suction, suitable for large industrial products baking!

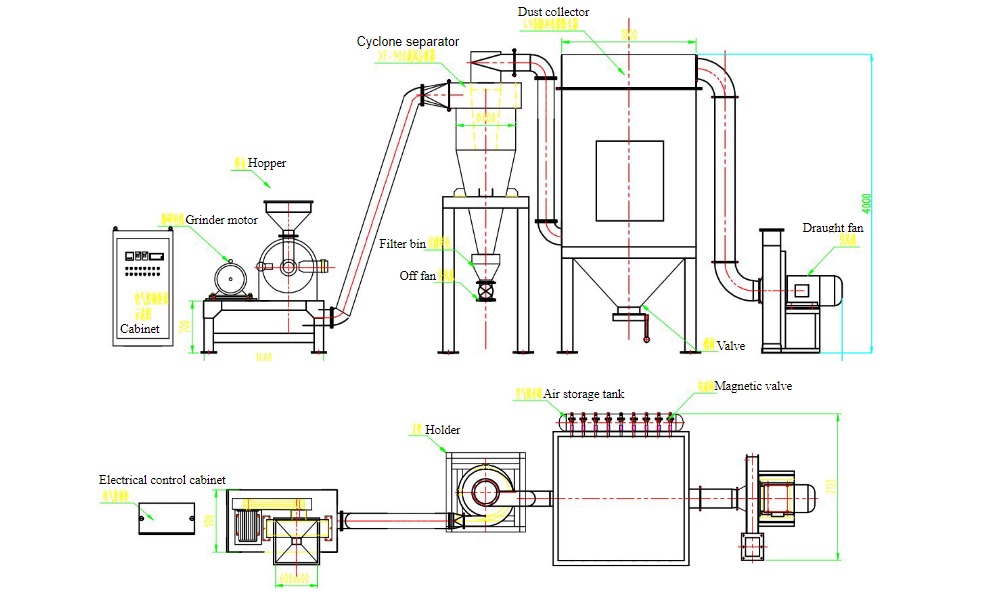

Hot air circulation system

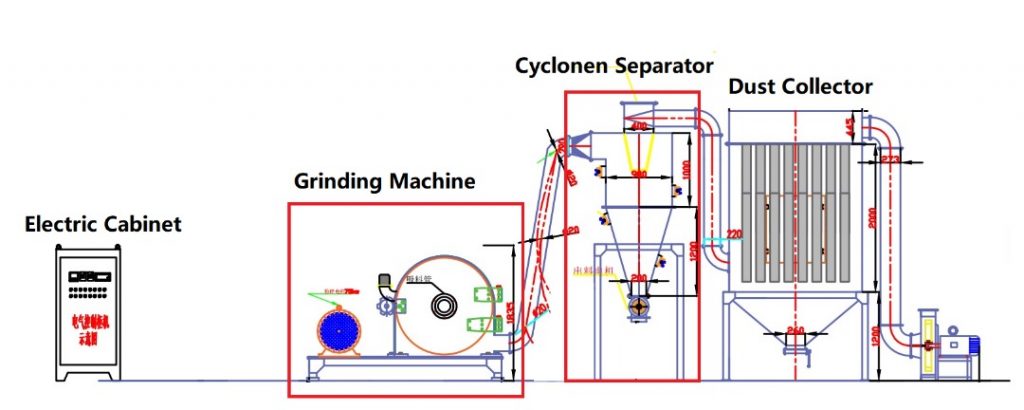

The hot air circulation system mainly includes cyclone separators, blowers, air filters and heaters. After the hot air from the dryer is removed by the cyclone separator, it is returned to the blower, and then filtered, it can be heated into the dryer. During the circulation process, the temperature of the rooin air continuously discharger part of the circulating air and supplement part of the fresh air after dehumidification and filtration. The characteristics of the dryer are that the slices are piston combed in the ten dryers, which can basically ensure the same small stay time of the slices in the drying process, and the drying quality is good, and the slices after drying can be connected continuously into the screw extruder hopper for spinning use, to avoid dry slices of moisture, and the structure of the dryer itself is relatively simple.

Hot Air Oven Working Principle

This dryer is suitable for vacuum drying powder or granular materials in the fields of medicine, food, and chemicals. It is particularly well-suited for drying materials that are heat-sensitive, prone to oxidation, or require preservation of their crystal structure. It is also ideal for drying materials that need to retain solvents for collection, as well as any materials that are hazardous or produce noxious fumes.

Ganulator and Dryer for Sale Review :

Fluid Bed Granulator

Dry Granulating Machine

BJB Grinding and Granulating Machine

BJB Swing Granulator

Rotary Granulator

BHLSG Wet Granulator

BSG Super Granulator

Application of Hot Air Oven:

The hot air circulation oven is used for heating and curing, drying, and dewatering materials in pharmaceutical, chemical, food, agricultural, aquatic, light industry, and other related industries. This includes raw materials, traditional Chinese medicine, extracts, powders, particles, dehydrated vegetables, and more.

The hot air oven is suitable for baking chemical gases and food processing to produce baked goods, curing ink, drying paint films, and more. It is widely used in various industries such as electronics, motors, communications, electroplating, plastics, hardware chemicals, instruments, printing, pharmaceuticals, PC boards, powder coating, dipping, spraying, glass, wood, building materials, as well as for precision baking, drying, tempering, preheating, shaping, and processing.

The oven uses internal heat circulation to ensure that objects are heated evenly.

Feature of Hot Air Oven:

- The oven features hot air circulation, which ensures high thermal efficiency and energy saving.

- The use of forced ventilation and the inclusion of an air duct in the oven allow materials to dry evenly.

- The oven runs smoothly, has automatic temperature control, and is easy to install and maintain.

- It has a wide range of applications and can dry various materials, making it an ideal general drying equipment.

- Temperature of Hot Air Circulation Oven: The hot air circulation oven is versatile and can dry various industrial materials, making it a general drying equipment. The typical temperature range of a hot air circulation oven is room temperature to +250°C, while high-temperature models can range from room temperature to +500°C.

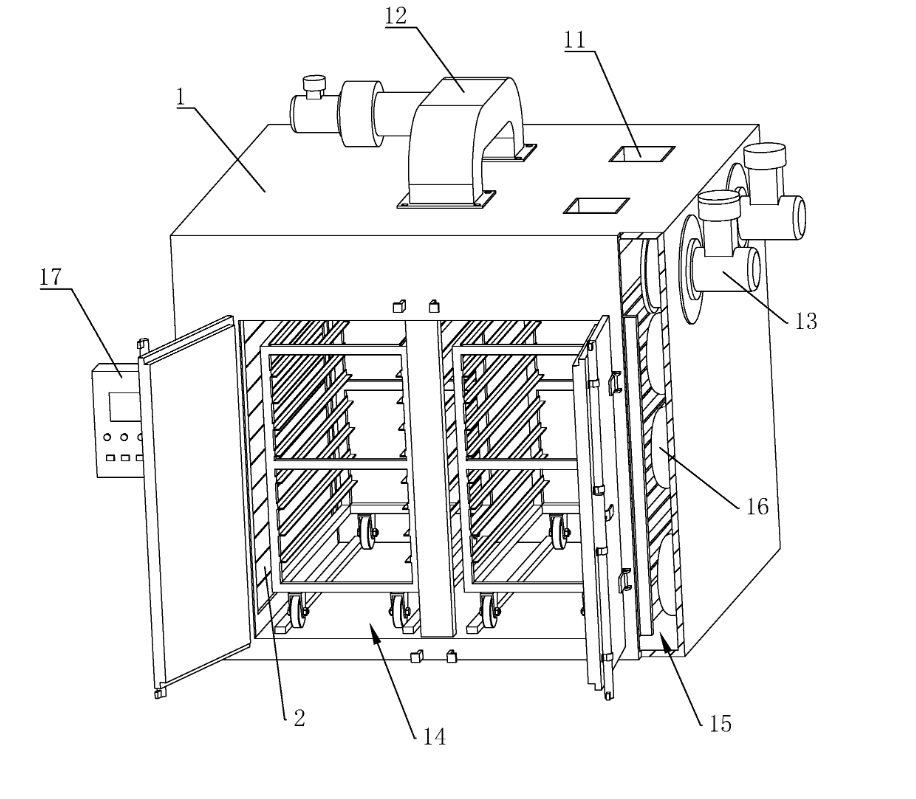

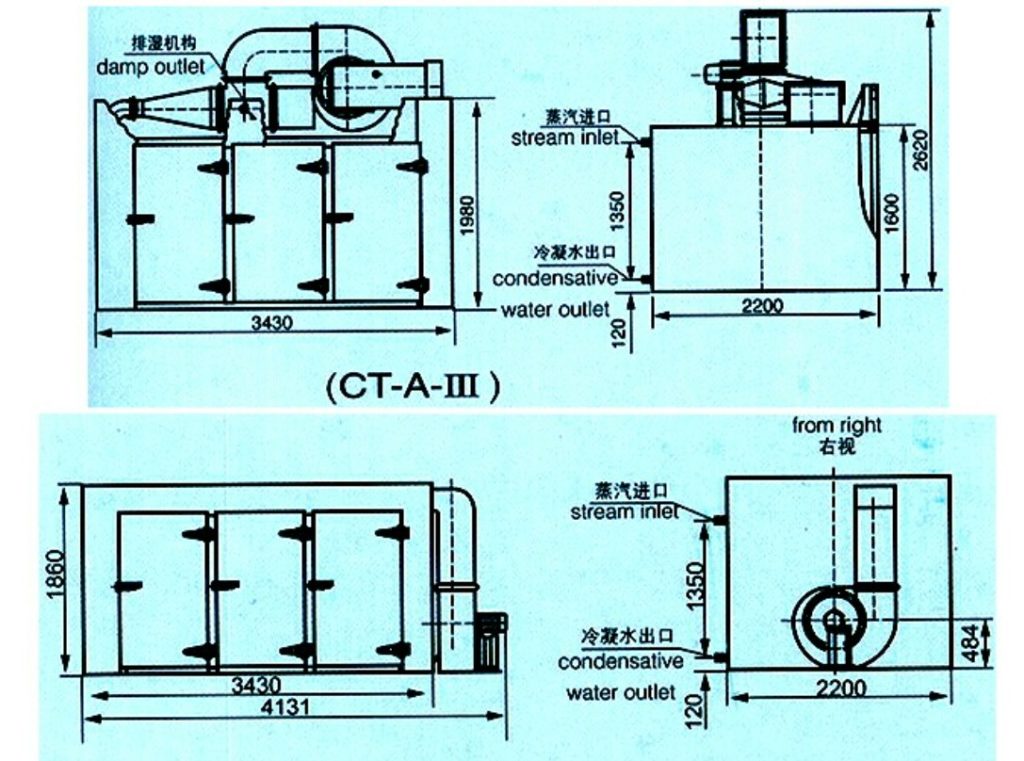

Structure of Hot Air Oven:

The hot air circulation oven is constructed using angle steel, stainless steel, and cold-rolled steel. The insulation layer is filled with high-density aluminum silicate cotton, which ensures the oven’s heat retention and user safety. The heater can be installed at the bottom, top, or sides of the oven.

What is the process of Hot Air Oven?

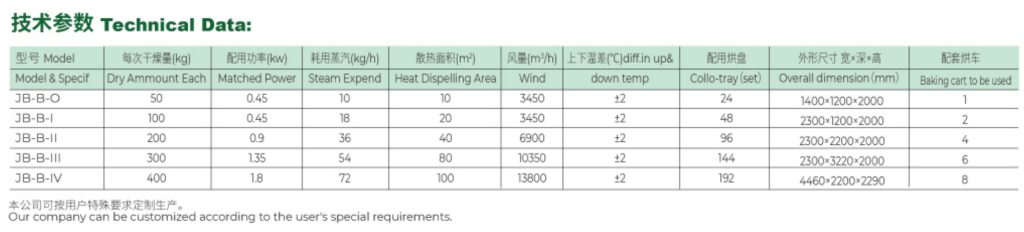

Hot Air Oven Dryer Parameter:

| Model | Capacity(KG/H) | Steam Expend(kg/h) | Matched Power(KW) | Tray(Set) | Baking Cart to be used |

| BJB-O | 50 | 10 | 0.45 | 24 | 1 |

| BJB-I | 100 | 18 | 0.45 | 48 | 2 |

| BJB-II | 200 | 36 | 0.9 | 96 | 4 |

| BJB-III | 300 | 54 | 1.35 | 144 | 6 |

| BJB-IV | 400 | 72 | 18 | 192 | 8 |

Double Cone Rotary Vacuum Dryer Price:

The BJB Grinding and Granulating Machine according to different model is around $580~$12,000. For more price information Please click.

Double Cone Rotary Vacuum Dryer Factory Information

| Business Type: | Manufacturer/Factory | Main Products: | Mill, grinder, granulator, mixer, Crushing Equipment |

| Number of Employees: | 100 | Year of Establishment: | 2014.05 |

| Production Capacity | 5000 Set/Year | After-sales Service: | Technical Support; on-line teach lessons |

| R&D Capacity: | ODM, OEM | Annual Output Value: | US$5 Million – US$10 Million |

| No. of R&D Staff: | 5 | No. of Production Lines: | 6 |

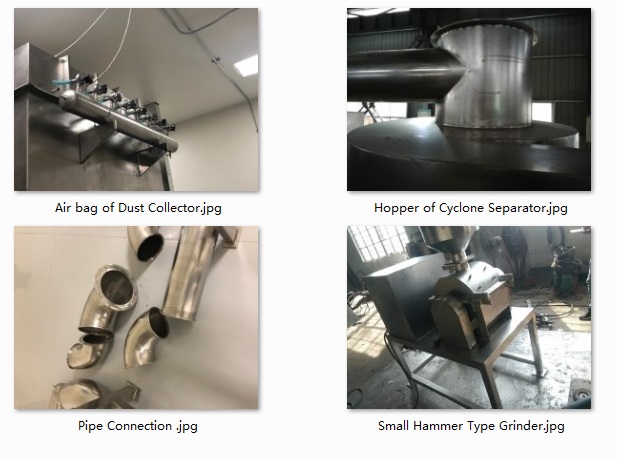

LK Mixer is a professional manufacturer for grinder, mixer and pulverizer, granulator. These machines are widely used in pharmaceutical, cosmetic, health care products and chemical industries. Our main product including granulating machine, grinder, mixer, dryer, etc. All mechanical products in accordance with the China GMP design requirements. And also we have other certifications such as CE, UL for motors.

Business Philosophy

“Quality is the main policy of sales” and “integrity is the principle of success” are the business philosophy of our people. We carry out one-year warranty, lifelong maintenance service, with technical consultation, with material test machine and other services, and long-term supply of equipment. Welcome new and old customers to negotiate cooperation!

Certifications:

About LKMixer

LKMixer is a professional manufacturer for fertilizer production line, grinder, mixer and granulator, shredder. These machines are widely used in food, pharmaceutical, cosmetic, health care products and chemical industries. The Food materials like Peanut, mushroom, seeds, potato, bean, tobacco, salt, cannabis, tea, Sugar, corn, Coffee, rice, pepper, grain as so on. Grinders have many types such as Pulse Dust Grinder which suitable for zero pollution environment, Turbine Mill which is suitable for coffee bean, 12-120mesh all can meet, Ultrafine Grinding Mill covers 80-200mesh, and also Winnowing Dust Grinder or other grinding machines like SF Hammer. Welcome to contact us for details. Contact us for more information. Proposal, catalog, quotation. Mobile/WhatsApp: +86 18019763531 Tel: +86 21 66037855 Email: sales@lkmixer.com

Contact Us

FAQ(Click and See More)

Why Choose Us?

We have 20 years manufacturing experiences; 15600 cubic meters factory area; 5000sets annual capacity; 55 professional engineers;

What’s your main market?

South America: Brazil, Colombia, Peru, Bolivia, Uruguay, Paraguay ;Romania;

USA with UL Certification

Middle East: Saudi, Arabia, Oman, Turkey

Europe: Russia, Australia, Belarus, Ukraine, Poland

Can you support OEM?

– Yes, OEM or ODM. Machine can be customized according to customer detail requirement, including capacity and voltages, motor certifications.

– Drawing and raw materials also can be customized.

What after-sale services?

– 7*24 customer service online;

– 7*24 engineers online services;

– 12 months warranty services.

WHAT kind of MACHINE YOUR COMPANY HAVE?

CAN YOU GIVE ME GUIDE ON OTHER MACHINE ? TO FULL MY PRODUCTION LINE

YES ! Our f have factory build more than 20 years now, we can design and customize whole line, besides of the grinding machine, mixing machine, we can also fully support to provide the washing machine, cutting machine, drying machine, packing machine, filling machine. Though we are not producing these machine, but our brother companies co-work together for over 20 years, we have rich experience in providing you a full effective production line, fully automatically or semi-automatically.

HOW TO VISIT YOUR COMPANY?

Our Factory located in Jiangsu Province, very near to Shanghai, you can fly to Shanghai Pudong Airport, we pick you up and take you by car 2 hours ride, can reach our factory, welcome your visit.

WHAT’S YOUR BEFORE & AFTER SERVICE ?

1) Before your purchasing, we need to know your detail request, such as what kind of material you want to grind and mixing, what final product powder or granule you want to reach. Because different material and powder sizes request of different machine to do. We can provide professional advice and rich experience help to choose machine. Most of the products we have already did before for other customer, trail test or run mass production, so we knows which machine is best in performance of grinding and mixing. This is of very importance in helping you choose the right model. We also wish this can help our customer a lot. Even the material we didn’t do before, we will prepare the same material and to do the trail test and send video to you for your reference.

2) One Year guarantee of machine quality. If the machine have problem within one year, we will send you the spare parts to you for replacement, but this not including the damage caused by human causes. We also have 24 hours on line guide for customer, if you have operation difficulty, we will guide by video and on line communication with our engineer for your emergency debug.

3) For small machine, we sell with whole machine, it’s no need to install, and easy to operation, no problems for operation. While for large machine, its’s also not difficult to install with video guideline, but if you need, we can assign our technicians to go abroad, the round ticket, food and residents will be paid by customer.

HOW ABOUT YOUR PAYMENT TERM?

Our payment term is T/T. 50% payment in advance, rest of 50% payment finish before the goods shipped. When we finish the machine production we will do trail test and run the machine take videos for your green light. You pay the rest of 50% payment then.

What are the different types of granulators?

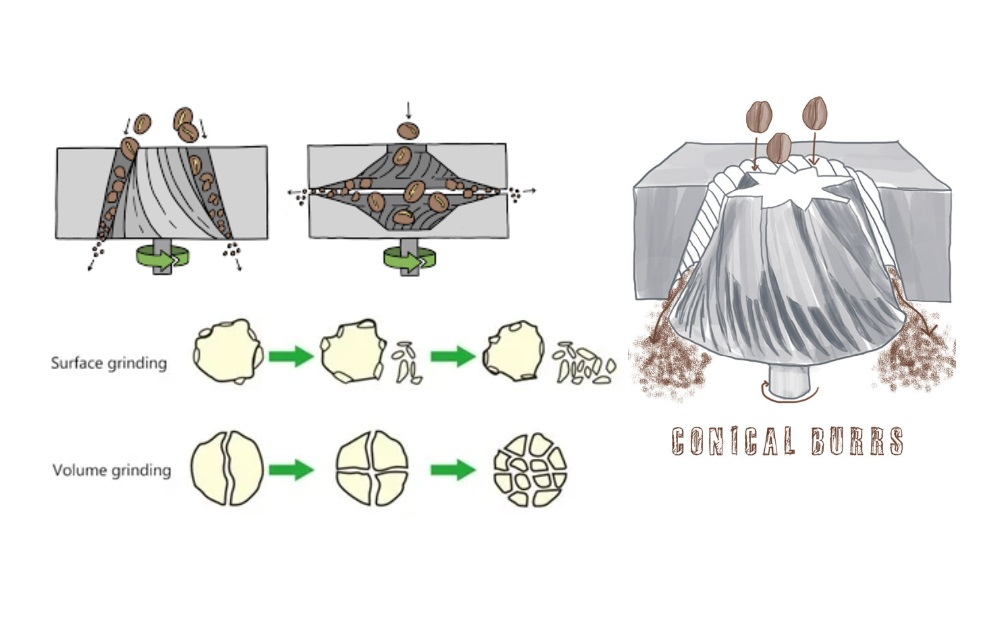

In terms of processing, pelletizer can be divided into two types: wet pelletizer, which uses liquid in the processing process, and dry pelletizer, which does not use liquid. Wet granulation involves a lot of water and detergent, and the purpose is to clean the contaminated material and also to cool the machine.

Matters need attention for operating Hot Air Oven:

The oven features hot air circulation, which ensures high thermal efficiency and energy saving.

The use of forced ventilation and the inclusion of an air duct in the oven allow materials to dry evenly.

The oven runs smoothly, has automatic temperature control, and is easy to install and maintain.

It has a wide range of applications and can dry various materials, making it an ideal general drying equipment.

Temperature of Hot Air Circulation Oven:

The hot air circulation oven is versatile and can dry various industrial materials, making it a general drying equipment. The typical temperature range of a hot air circulation oven is room temperature to +250°C, while high-temperature models can range from room temperature to +500°C.”

User

correct grammar error: 1. Close the air switch of the circulating oven, set the heating temperature at 250℃ and the overtemperature alarm temperature at 260℃ according to the operating instructions of the oven, and start the automatic operation program after the holding time for 1 h. The indicator lights of the circulating fan, inlet fan, disc valve and heating of the oven will light up in sequence, indicating that the program is running normally. After 2.5 hours of heating operation, the temperature still does not reach the set value, if the heating time is too long, it will cause the heated glass container to be fragile, and the broken bottle rate will increase. At the same time, it causes energy waste and increases power consumption. And the working cycle of the oven is lengthened, which can not complete the process link on time under the two-shift system of the normal production position, almost miss the process plan of the production task, and increase the production cost. It takes 2.5h for the normal full container temperature to be heated from room temperature to 250℃, and it takes about 6h for 1 working cycle.

Oven, drying box use manual 1 1 Before use must pay attention to the power supply voltage can meet. When using, the grounding cable of the power socket must be grounded according to the rules.

When using power, do not touch the electrical appliances on the left side of the box with your hand or wipe with wet cloth and rinse with water. The power supply should be cut off during inspection.

The power cord should not be wrapped around metal objects, and should not be set in a low temperature or wet center to avoid leakage caused by rubber aging.

Do not overcrowd the items in the box, and it is necessary to leave space for natural convection of the atmosphere, so that the wet atmosphere can slow down and escape at the top of the wind.

Check whether the silver contact of the temperature conditioner can be hairy or uneven. If so, the contact can be sanded flat with fine gauze and then used, and should be wiped with a clean cloth often to make it have good contact (note that the power supply must be cut off). Do not strike the metal pipe of the indoor temperature conditioner so as not to affect the flexibility.

Do not put flammable materials in the dry box without explosion-proof installation.

After each use, the power supply must be partially cut off, often insisting that the inside and outside of the box are clean. Hang the appropriate logo after the clean end. See details

Ovens, drying boxes User manual two

Explosive, flammable and volatile items should not be put into the drying oven, so as not to cause explosion.

Sample shelf uniform load should not exceed 20kg.

Items can not be placed on the shelf between the sample room and the heating room, so as not to affect the heat exchange.

Before use, it is necessary to reflect whether the nickel wire is stacked or short circuit.

The heating indicator light is not bright, there are generally three reasons: ① the lamp is broken; ② Light bulb contact is poor; ③ The heating pieces are faulty.

The maintenance and protection of electric dry box: 6. Open the heating switch and do not heat. There are generally four reasons: ① nickel-chromium wire break; ② Switch and line welding; ③ Temperature control knob refers to the zero position (rotate the temperature control knob to the specified temperature scale); ④ Relay protection.

Temperature control failure, there are generally three reasons: ① temperature probe protection (change the thermistor); ② Relay protection; (3) Failure of other parts of the temperature control system (use a multimeter to detect the fault and repair it according to the situation).

Ovens, drying boxes User manual three

The use of the instrument must be assigned, and the external power supply should be cut off at the end of the use of the equipment to avoid accidents.

When placing the test in the task room, it should not be too dense, so as not to affect the general activity of the air flow in the task room, there must be a gap of 10 ~ 20mm between each item, and it should be placed symmetrically, the items placed on each layer of shelf should be interwoven, and the interval between the bottom shelf and the bottom of the task room must be greater than 100mm.

Leave a certain space around the equipment to facilitate heat dissipation, operation and protection of the equipment.

Avoid sharp objects to scratch the equipment.

Please do not disassemble electrical components and other (part) of the equipment, so as not to protect the electrical control line, and affect the function of the equipment.

When storing and using equipment, there are no flammable, explosive and corrosive objects around.

Do not put inflammable, explosive and volatile materials into the equipment.

ChatGPT

Here’s the corrected text:

“1. Close the air switch of the circulating oven and set the heating temperature to 250°C and the overtemperature alarm temperature to 260°C according to the operating instructions of the oven. Begin the automatic operation program after allowing the oven to hold at this temperature for 1 hour. The indicator lights for the circulating fan, inlet fan, disc valve, and heating of the oven will light up in sequence, indicating that the program is running normally. After 2.5 hours of heating operation, if the temperature still does not reach the set value, an extended heating time can make heated glass containers fragile, increasing the rate of broken bottles. This also causes energy waste, increased power consumption, and a prolonged working cycle of the oven. It can disrupt the two-shift system in the normal production process, potentially causing missed process plans and increased production costs. In a normal, full container, it takes 2.5 hours to heat from room temperature to 250°C, and about 6 hours for one working cycle.

Oven and Drying Box User Manual

Before use, ensure the power supply voltage meets the necessary requirements. When using the oven, the power socket’s grounding cable must be grounded according to regulations.

Do not touch electrical appliances on the left side of the oven with your hand, or clean them with a wet cloth or water. Power should be cut off during inspections.

The power cord should not be wrapped around metal objects or placed in low temperature or wet environments to avoid leakage due to rubber aging.

Avoid overcrowding the oven, and leave space for natural convection to allow for proper air circulation.

Check whether the silver contact of the temperature conditioner is worn or uneven. If so, sand the contact flat with fine gauze, then wipe it clean with a cloth for good contact (note: always cut off power supply first). Do not strike the metal pipe of the indoor temperature conditioner to avoid impacting its flexibility.

Do not put flammable materials in the drying box without proper explosion-proof installation.

After each use, cut off the power supply and keep the inside and outside of the box clean. Hang an appropriate sign once cleaning is completed.

Ovens and Drying Boxes User Manual – Section Two

Do not place explosive, flammable, or volatile items in the drying oven to avoid causing explosions.

The uniform load on the sample shelf should not exceed 20kg.

Do not place items on the shelf between the sample room and the heating room to avoid disrupting heat exchange.

Before use, check for stacked or short-circuited nickel wires.

If the heating indicator light is not lit, there are generally three possible reasons: ① The lamp is broken; ② Poor bulb contact; ③ Faulty heating elements.

If the heating switch is on but there’s no heat, there are generally four possible reasons: ① Nickel-chromium wire breakage; ② Switch and wire welding issues; ③ The temperature control knob is set to zero (adjust it to the desired temperature); ④ Relay protection.

Temperature control failures can arise from three possible reasons: ① Temperature probe protection (replace the thermistor); ② Relay protection; ③ Other parts of the temperature control system (use a multimeter to detect and repair faults).

Ovens and Drying Boxes User Manual – Section Three

Assign someone to use the instrument, and cut off the external power supply when finished using the equipment to avoid accidents.

Avoid placing items too densely in the oven, as this may interfere with air circulation. Ensure a gap of 10–20mm between items and place them symmetrically. On each shelf, items should be interwoven, and the space between the bottom shelf and the bottom of the oven must be greater than 100mm.

Leave space around the equipment for heat dissipation, operation, and maintenance.

Avoid scratching the equipment with sharp objects.

Do not disassemble electrical components or other parts of the equipment, as this may damage the electrical control lines and impact the function of the equipment.

Ensure there are no flammable, explosive, or corrosive objects around when storing or using the equipment.

Do not place flammable, explosive, or volatile materials inside the equipment.

What is the difference between hot air oven and autoclave?

Autoclave is high-pressure steam sterilization, relying on high temperature water vapor in high pressure environment sterilization;

Oven heating 120 degrees Celsius is relying on electric heating wire baking heating, dry heat, its sterilization effect is worse than high-pressure steam sterilization

What are the advantages and disadvantages of hot air oven?

I. Advantages

High efficiency and energy saving hot air circulation oven distributes heat evenly to the entire oven through circulation air, so that the heat is fully utilized. Compared with traditional ovens, hot air circulation ovens can save energy and time and improve production efficiency.

Easy to operate

The operation of the hot air circulation oven is simple and easy to understand, only need to control the running time and temperature. There is no need for complex manual intervention, reducing labor costs and improving production efficiency.

Wide range of application

Hot air circulation oven is suitable for drying various materials, such as electronic components, food, chemical materials and so on. And it can adapt to the drying needs of different products by adjusting the running time and temperature.

Ii. Disadvantages

High initial investment cost

The manufacture of hot air circulation ovens requires sophisticated technology and equipment, so the initial investment cost is high. However, with the development of technology, the manufacturing cost of hot air circulation oven is gradually reduced, and more and more enterprises have begun to adopt it.

Loud noise

When the hot air circulation oven is running, some equipment will produce large noise. However, through the optimization of operating equipment and noise reduction processing, the impact of noise on production and employees can be effectively reduced.

Third, the application of the occasion

Mass production enterprises

For businesses that need a lot of drying, hot air circulation ovens can precisely control temperature and drying time, improving efficiency and quality.

Enterprises with high environmental protection requirements

Compared with traditional ovens, hot air circulation ovens have less exhaust emissions during the drying process and are more environmentally friendly.

Drying products with strict requirements

For some products with special drying requirements, such as electronic components, materials, etc., the hot air circulation oven can be adjusted according to product requirements to improve the drying quality.

In general, the advantages of hot air circulation oven are high efficiency and energy saving, easy operation and wide application range, but the initial investment cost is higher and the noise is larger. For enterprises that need a lot of drying, enterprises with high environmental protection requirements, and products with strict drying requirements, hot air circulation ovens can be used.