Rotary Granulator

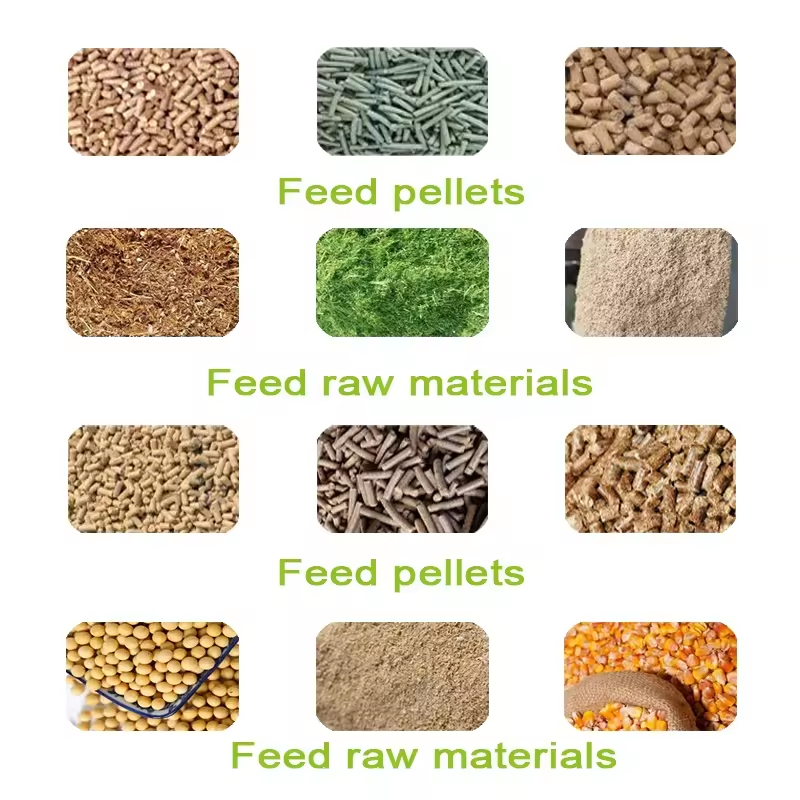

- Material: powder and powder, powder and bond;

- Capacity: 100-350KG;

- Granulator Diameter: 1-3mm;

- Total Power: 3/4 5.5/7.5KW;

- Knife Size: 250, 300KG;

- Application: Pharmaceuticals, Nutraceuticals, Food Products, Chemicals, Fertilizer, Stucco, Clay, Potting Soils.

- Notice: This is just an example. Please contact with our sales for choosing the right model.

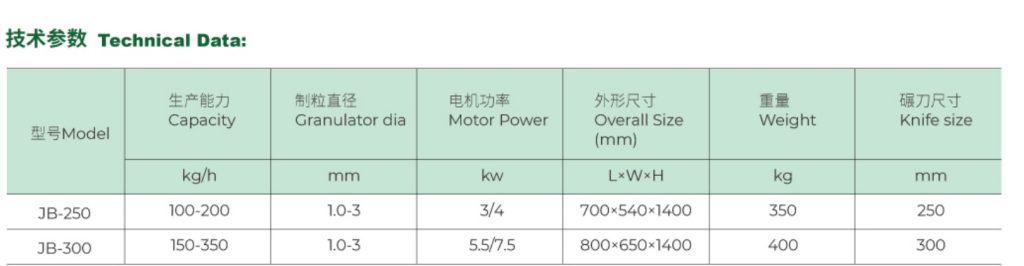

Rotary Granulator Parameter:

| Model | Capacity(KG/H) | Granulator diameter(mm) | Dimension(mm L*W*H) | Weight(KG) | Motor Power(KW) | Knife Size(MM) |

| BJB-250 | 100-200 | 1.0-3 | 750*540*1400 | 350 | 3/4 | 250 |

| BJB-350 | 150-350 | 1.0-3 | 800*650*1400 | 400 | 5.5/7/5 | 300 |

Rotary Granulator Price:

The Rotary Granulator according to different model is around $580~$12,000. For more price information Please click.

Rotary Granulator Meaning:

Rotary Granulator machine and material contact parts are made of stainless steel, beautiful appearance, reasonable structure, high pelletizing molding rate, beautiful particles, automatic discharge, avoid manual discharge caused by particle damage, and suitable for flow operation.

Rotary Granulator Application:

The rotary granulator is used in pharmaceutical, food, powder, chemical, solid beverage and other industries to make the stirred material into the city particles, especially suitable for materials with high viscosity. The machine is made of stainless steel where the part is in contact with the material, beautiful appearance, reasonable structure, high pelletizing molding rate, beautiful particles, automatic discharge, avoid the particle damage caused by manual discharge, and suitable for flow operation. The granulator is used in pharmaceutical, food, powder, chemical, solid beverage and other industries to make the stirred material into the city particles, especially suitable for materials with high viscosity. The machine is made of stainless steel where the part is in contact with the material, beautiful appearance, reasonable structure, high pelletizing molding rate, beautiful particles, automatic discharge, avoid the particle damage caused by manual discharge, and suitable for flow operation.

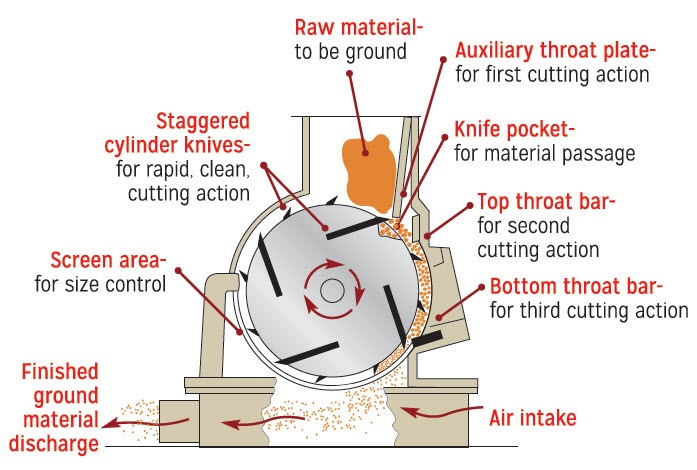

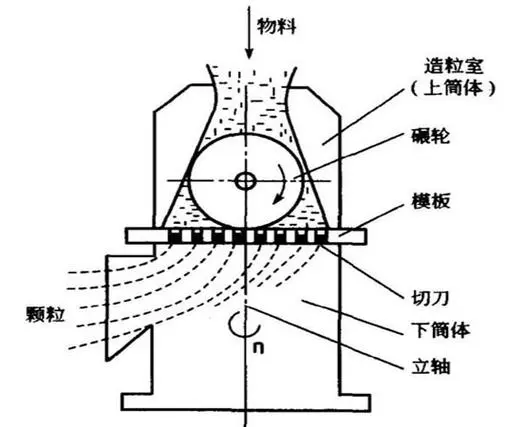

Rotary Granulator Working Principle

- Tray filler: At the beginning of the work, put the material to be pelleted into the tray of the rotary granulator.

- Rotating motion: After starting the rotating pellet machine, the tray begins to rotate. The rotary pellet machine usually uses a ring tray with a plurality of grooves on the tray to accommodate the material.

- Process control: By controlling parameters such as rotation speed, tilt Angle and humidity, the working process of the granulator can be adjusted to achieve the required granulation effect;

- Particle formation: In the process of rotation of the tray, the material is gradually affected by the centrifugal force and gradually overflow from the groove. Under the action of centrifugal force, the material will gradually form particles;

- Particle dispersion: with the rotation of the tray, the particles will pass through the dispersion device to disperse the particles and avoid the adhesion between the particles;

- Drying process: In some pellet machines, drying devices will also be set up to dry particles with high humidity and improve the quality of particles;

- Discharge and collection: After a period of rotating movement, the particles will be finished particles from the discharge port, and collected through the collection device in general, the rotary pellet machine by putting the material into the rotating tray, the use of centrifugal force to gradually form particles, and through the control of parameters and a series of process steps, and finally get the required particle products.

Rotary Granulator Fertilizer

1. the granulation machine is a kind of swinging effect of rotating drum, through the wire sieve can be wet powder raw materials into particles, can also be widely used to crush has become a block and become ready-made particles.

2. in the field of chemicals used as wet powder into particles, dried for pressing tablets, and can be crushed during storage and condensed into blocks or in the chemical processing of the block, used in the food industry to deal with candy and sugar mixture and malted milk and other products, in other industries such as ceramics, plastics and other mixtures become formed particles. 3, it is not suitable for semi-solid, fluid, slurry or wear.

Rotary Granulator Design

The two ends are consistent with the inner and outer ring speed of the die disk, and there is no dislocation friction between the wheel and the die, which reduces the resistance, reduces the kinetic energy loss, and extends the service life of the die, which is a major difference with similar compression molding equipment. It adopts the screw center pressure regulating mechanism, the mold gap is large and small, suitable for different materials, to ensure the pressing effect. Its press wheel adopts large body and wide groove, pressure and wear resistance, the press wheel adopts multiple uniform cloth, stable operation, while increasing the pressing area, improving the production efficiency. Wood chips, straw compression molding needs a lot of pressure, in the same kind of granulation, pressing block, rod making equipment, the press wheel component is the central part of the entire equipment. “Cone wheel flat die” has the advantage of arbitrarily increasing the pressure wheel is not comparable to other equipment, such as the ring model granulator due to the diameter of the ring die, the pressure wheel can not increase, resulting in the pressure wheel bearing chamber becomes smaller, the assembled bearing does not have a strong ability to withstand pressure, and the bearing damage leads to the disadvantage of three stops and two rest of the equipment. The model compression molding diversification, round rod, square, particles as long as the exchange of the mold can be done, to adapt to different materials compression molding, to achieve the best benefits. The granulation chamber is equipped with an observation door, which is easy to check at any time for maintenance and repair.

| Business Type: | Manufacturer/Factory | Main Products: | Mill, grinder, granulator, mixer, Crushing Equipment |

| Number of Employees: | 100 | Year of Establishment: | 2014.05 |

| Production Capacity | 5000 Set/Year | After-sales Service: | Technical Support; on-line teach lessons |

| R&D Capacity: | ODM, OEM | Annual Output Value: | US$5 Million – US$10 Million |

| No. of R&D Staff: | 5 | No. of Production Lines: | 6 |

LK Mixer is a professional manufacturer for grinder, mixer and pulverizer, granulator. These machines are widely used in pharmaceutical, cosmetic, health care products and chemical industries. Our main product including granulating machine, grinder, mixer, dryer, etc. All mechanical products in accordance with the China GMP design requirements. And also we have other certifications such as CE, UL for motors.

Business Philosophy

“Quality is the main policy of sales” and “integrity is the principle of success” are the business philosophy of our people. We carry out one-year warranty, lifelong maintenance service, with technical consultation, with material test machine and other services, and long-term supply of equipment. Welcome new and old customers to negotiate cooperation!

Certifications:

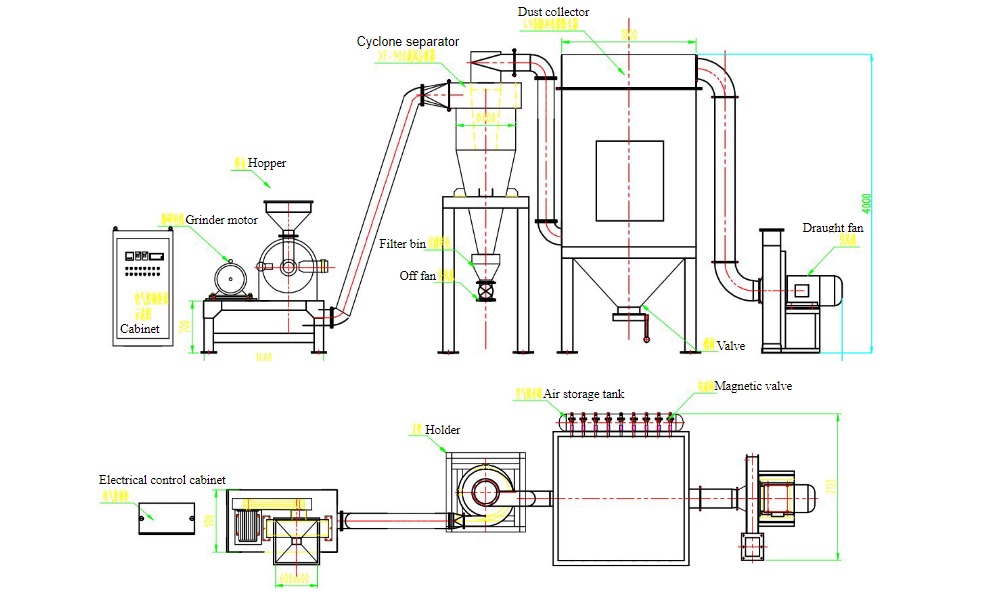

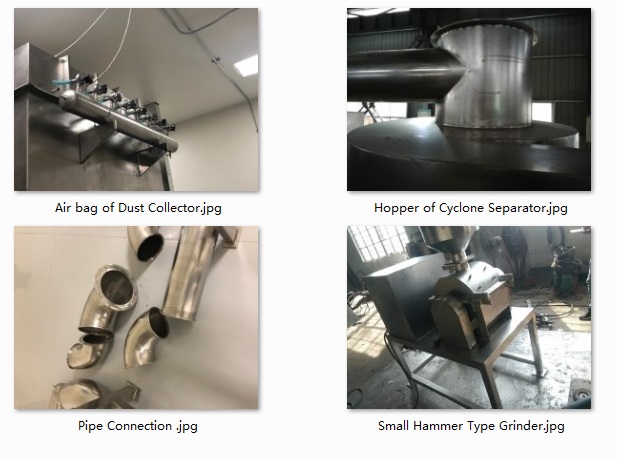

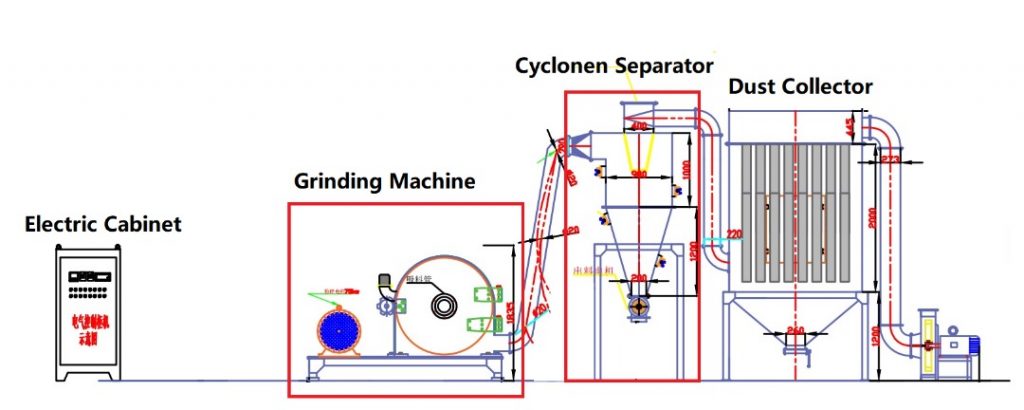

Industrial Pepper Grinder Diagram of Design

Electric Cabinet with UL Certification

Cyclone Processor and Motors:

Spare Parts:

Small Machine Packing:

Small machine packed with export fumigation-free wooden cases, goes with bulk shipment or in container.

Large Machine Packing:

Shipment Show Case: Small grinder machine ship for Masala, Pakistan, Kenya, Nepal, India…

Granulator for Sale Review :

About LKMixer

LKMixer is a professional manufacturer for fertilizer production line, grinder, mixer and granulator, shredder. These machines are widely used in food, pharmaceutical, cosmetic, health care products and chemical industries. The Food materials like Peanut, mushroom, seeds, potato, bean, tobacco, salt, cannabis, tea, Sugar, corn, Coffee, rice, pepper, grain as so on. Grinders have many types such as Pulse Dust Grinder which suitable for zero pollution environment, Turbine Mill which is suitable for coffee bean, 12-120mesh all can meet, Ultrafine Grinding Mill covers 80-200mesh, and also Winnowing Dust Grinder or other grinding machines like SF Hammer. Welcome to contact us for details. Contact us for more information. Proposal, catalog, quotation. Mobile/WhatsApp: +86 18019763531 Tel: +86 21 66037855 Email: sales@lkmixer.com

Contact Us

FAQ(Click and See More)

Why Choose Us?

We have 20 years manufacturing experiences; 15600 cubic meters factory area; 5000sets annual capacity; 55 professional engineers;

What’s your main maket?

South America: Brazil, Colombia, Peru, Bolivia, Uruguay, Paraguay ;Romania;

USA with UL Certification

Middle East: Saudi, Arabia, Oman, Turkey

Europe: Russia, Australia, Belarus, Ukraine, Poland

Can you support OEM?

– Yes, OEM or ODM. Machine can be customized according to customer detail requirement, including capacity and voltages, motor certifications.

– Drawing and raw materials also can be customized.

What after-sale services?

– 7*24 customer service online;

– 7*24 engineers online services;

– 12 months warranty services.

WHAT kind of MACHINE YOUR COMPANY HAVE?

CAN YOU GIVE ME GUIDE ON OTHER MACHINE ? TO FULL MY PRODUCTION LINE

YES ! Our f have factory build more than 20 years now, we can design and customize whole line, besides of the grinding machine, mixing machine, we can also fully support to provide the washing machine, cutting machine, drying machine, packing machine, filling machine. Though we are not producing these machine, but our brother companies co-work together for over 20 years, we have rich experience in providing you a full effective production line, fully automatically or semi-automatically.

HOW TO VISIT YOUR COMPANY?

Our Factory located in Jiangsu Province, very near to Shanghai, you can fly to Shanghai Pudong Airport, we pick you up and take you by car 2 hours ride, can reach our factory, welcome your visit.

WHAT’S YOUR BEFORE & AFTER SERVICE ?

1) Before your purchasing, we need to know your detail request, such as what kind of material you want to grind and mixing, what final product powder or granule you want to reach. Because different material and powder sizes request of different machine to do. We can provide professional advice and rich experience help to choose machine. Most of the products we have already did before for other customer, trail test or run mass production, so we knows which machine is best in performance of grinding and mixing. This is of very importance in helping you choose the right model. We also wish this can help our customer a lot. Even the material we didn’t do before, we will prepare the same material and to do the trail test and send video to you for your reference.

2) One Year guarantee of machine quality. If the machine have problem within one year, we will send you the spare parts to you for replacement, but this not including the damage caused by human causes. We also have 24 hours on line guide for customer, if you have operation difficulty, we will guide by video and on line communication with our engineer for your emergency debug.

3) For small machine, we sell with whole machine, it’s no need to install, and easy to operation, no problems for operation. While for large machine, its’s also not difficult to install with video guideline, but if you need, we can assign our technicians to go abroad, the round ticket, food and residents will be paid by customer.

HOW ABOUT YOUR PAYMENT TERM?

Our payment term is T/T. 50% payment in advance, rest of 50% payment finish before the goods shipped. When we finish the machine production we will do trail test and run the machine take videos for your green light. You pay the rest of 50% payment then.

What are the different types of granulators?

In terms of processing, pelletizer can be divided into two types: wet pelletizer, which uses liquid in the processing process, and dry pelletizer, which does not use liquid. Wet granulation involves a lot of water and detergent, and the purpose is to clean the contaminated material and also to cool the machine.