WCH Horizontal Tank Mixer

WCH Double Pulp Tank Mixer

- Suitable Blending Material: Dry Powder , Wet Powder, advocate complementary material, suitable for mixed semi-solid liquid materials or viscosity is too large.

- Batch Volumn: 100-600L;

- Stirring Speed: 24 r/min;

- Machine Weight:450-1300(KG);

- Total Power: 4-11kw

- Application: Pharmaceuticals, chemical, food.

- Price: Cost around $188~7659.(Depend on Models and special customization).

- HS code: 8479820090

What is Horizontal Tank Mixer?

A horizontal tank mixer is a type of equipment used in various industries to blend or mix substances. Unlike vertical mixers, which stand upright, horizontal tank mixers are designed with a horizontal orientation. They are commonly used in applications such as food processing, chemical manufacturing, and pharmaceutical production.

These mixers typically consist of a tank-shaped container lying on its side, equipped with an agitator or mixing device. The agitator can be customized to suit the specific materials being mixed. It rotates within the tank to thoroughly combine ingredients and create a consistent mixture.

One of the key advantages of horizontal tank mixers is their ability to provide a more uniform blend of materials, which can be crucial for certain applications. Additionally, they are well-suited for incorporating ingredients with low inclusion rates, often as low as 1 kg per metric ton. This precision makes them particularly useful in industries where accurate mixing is essential.

Horizontal mixers also tend to have little or no residue left in the tank after mixing, thanks to their design, which ensures complete discharge of the mixed material. This is a notable advantage in applications where cross-contamination or leftover material can be problematic.

In summary, a horizontal tank mixer is a specialized mixing equipment with a horizontal design, ideal for applications requiring precise and uniform blending of ingredients while minimizing leftover residue in the tank.

Structure(Design):

A Tank Mixer comprises several key components, including a tank cover, tank mixer motor,an agitator, bearings, a driving mechanism, and a sealing device. Depending on your requirements, you can also add heating or cooling equipment to the tank.

Both the tank body and cover come with various features like inlets, outlets, observation ports, temperature and pressure gauges, steam distillation ports, and safety vents. The type of agitator used can vary based on the specific production process, with options such as paddle, anchored, frame, or propeller types. If needed, the factory can customize the design to meet your specific needs.

Application:

A Tank Mixer is a hygienic and clean piece of equipment with a fully enclosed vertical design. It comes equipped with functions for heating, cooling, insulating, and mixing. This versatile tank is specially designed for use in the food, dairy, beverage, pharmaceutical, winemaking, flavor, and chemical industries.

The tanks feature a jacketed layer, allowing you to heat or cool the contents by introducing steam or cooling water. The agitator within the tank ensures that the materials are thoroughly mixed at the most suitable temperature.

What does a tank mixer do?

A tank mixer plays a crucial role in winemaking by ensuring that everything inside the tank, like the grape juice and other ingredients, is mixed thoroughly. This gentle stirring action takes place during fermentation, maintaining an even temperature and making sure yeast and nutrients are evenly distributed. It’s also handy when it comes to creating a uniform blend before the wine is bottled, ensuring that every bottle of wine is consistent in quality.

Horizontal Tank Mixer is ideal for blending various ingredients, such as short doughs, tortillas, fillings, pie doughs, health breads, cheesecakes, muffin batter, and a range of other recipes. These mixers come with different mixing arms that can be tailored to the specific type of dough or mixture you’re working with, offering a high degree of customization.

Technical Performance:

Heating Method: The tank can be heated using either steam or electrical heating to generate heat for material sterilization.

Working Principle(tank mixer design):

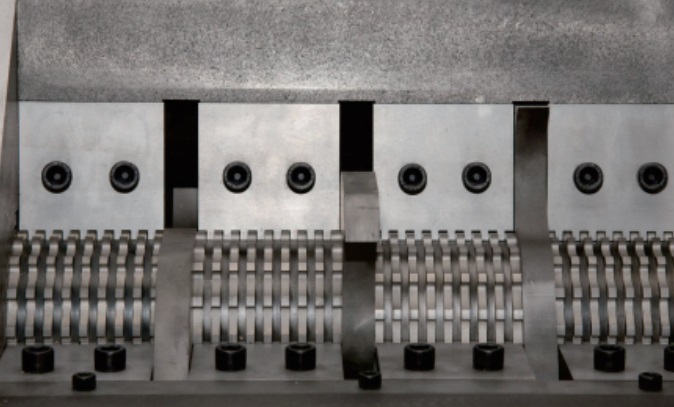

This machine is a horizontal trough-type double-paddle mixer, primarily used in the pharmaceutical industry to uniformly mix dry or wet powdered materials in different proportions. During the mixing process, it does not cause material dissolution, evaporation, or deterioration. The machine is also suitable for the chemical and food industries, where it mixes different main and auxiliary materials, making it ideal for mixing semi-solids, liquids, or highly viscous materials.

Structural features: The machine has an integral frame, and its transmission system operates smoothly. The mixing paddles and parts that come into contact with materials are made of stainless steel, providing excellent corrosion resistance to maintain the quality of the mixed materials without contamination or discoloration. The transmission mechanism mainly uses pot wheels, pot rods, and gear drives, resulting in minimal noise during operation. It also has sufficient oil storage capacity for effective lubrication, enhancing the machine’s lifespan. The machine is equipped with electrical controls for easy operation and utilizes automatic incremental feeding, reducing the operator’s workload. It is suitable for the pharmaceutical, chemical, and food industries for mixing uniform or pasty materials. The machine achieves uniform mixing through mechanical rotation, causing the dual-S-shaped mixing blades to rotate, propelling the materials to flip back and forth evenly.

How to Calculate the Volume of tank mixer (gallon to liter)?

To convert gallons to liters, you can use the conversion factor of 1 US gallon being approximately equal to 3.78541 liters. Here are the conversions for the given tank mixers:

- 5 gallon tank mixer:

5 gallons × 3.78541 liters/gallon ≈ 18.93 liters - 30 gallon tank mixer:

30 gallons × 3.78541 liters/gallon ≈ 113.56 liters - 300 gallon tank mixer:

300 gallons × 3.78541 liters/gallon ≈ 1,135.14 liters - 500 gallon tank mixer:

500 gallons × 3.78541 liters/gallon ≈ 1,892.71 liters - 1000 gallon tank mixer:

1000 gallons × 3.78541 liters/gallon ≈ 3,785.41 liters

So, the tank mixers in liters are approximately as follows:

- 1000 gallon tank mixer ≈ 3,785.41 liters

- 30 gallon tank mixer ≈ 113.56 liters

- 300 gallon tank mixer ≈ 1,135.14 liters

- 5 gallon tank mixer ≈ 18.93 liters

- 500 gallon tank mixer ≈ 1,892.71 liters

Electric Mixer Tank for Sale (Stainless Steel):

Universal Grinder Youtube Video (See More)

About LKMixer

LKMixer is a professional manufacturer for fertilizer production line, grinder, mixer and granulator, shredder. These machines are widely used in food, pharmaceutical, cosmetic, health care products and chemical industries. The Food materials like Peanut, mushroom, seeds, potato, bean, tobacco, salt, cannabis, tea, Sugar, corn, Coffee, rice, pepper, grain as so on. Grinders have many types such as Pulse Dust Grinder which suitable for zero pollution environment, Turbine Mill which is suitable for coffee bean, 12-120mesh all can meet, Ultrafine Grinding Mill covers 80-200mesh, and also Winnowing Dust Grinder or other grinding machines like SF Hammer. Welcome to contact us for details. Contact us for more information. Proposal, catalog, quotation. Mobile/WhatsApp: +86 18019763531 Tel: +86 21 66037855 Email: sales@lkmixer.com