LDH Ploughshare Mixer

LDH Horizontal Ploughshare Mixer

- HS code: 8479820090

- Mixed amount/bach KG : 40-3600L;

- Machine Weight: 150-3800(kg);

- Total Power: 3-37 KW

- Weight: 440-660KG;

- Application: This machine finds extensive applications across diverse industries, including chemicals, pharmaceuticals, pesticides, plastics, rubber, chemical fertilizers, building materials, concrete admixtures, foodstuffs like monosodium glutamate, feed additives, dyes, metallurgy, mining, and others. It excels in mixing solid-to-solid (powder with powder), solid-to-liquid (where a liquid is added to the powder), granulation, drying, concentration, and other composite processes. It is a versatile and highly adaptable mixing equipment suitable for a wide range of multifunctional applications.

- Price and cost: 1,388USD~11,000USD.

Parameters of High Speed Mixer:

| Model | LDH-0.1 | LDH-0.3 | LDH-0.5 | LDH-1 | LDH-2 | LDH-4 | LDH-6 | LDH-10 |

| Total Volume(m³) | 0.1 | 0.3 | 0.5 | 1 | 2 | 4 | 6 | 10 |

| Loading Coefficient | 0.3~0.6 | 0.3~0.6 | 0.3~0.6 | 0.3~0.6 | 0.3~0.6 | 0.3~0.6 | 0.3~0.6 | 0.3~0.6 |

| Mixing time(min) | 4-8 | 4-8 | 4-8 | 4-8 | 8-15 | 8-15 | 8-15 | 8-15 |

| Fineness of material | 40-850 | 40-850 | 40-850 | 40-850 | 40-850 | 40-850 | 40-850 | 40-850 |

| Power Plow knife(kw) | 3 | 5.5 | 7.5 | 11 | 15~18.5 | 22 | 30~35 | 37~45 |

| Power Flying knife(kw) | 1.5*2 | 1.5*2 | 1.5*2 | 1.5*2 | 1.5*3 | 1.5*4 | 1.5*5 | 1.5*5 |

| Weight(KG) | 450 | 760 | 860 | 1520 | 2110 | 2120 | 6800 | 7200 |

| Dimension(mm) | 1850×750×720 | 2230 x1000 ×1200 | 2550×1120 ×.1250 | 3000×1230 ×1500 | 3900x 1500 0170 | 4400×1850 ×2200 | 520× 2000×2300 | 100×2500×2600 |

What is Ploughshare Mixer?

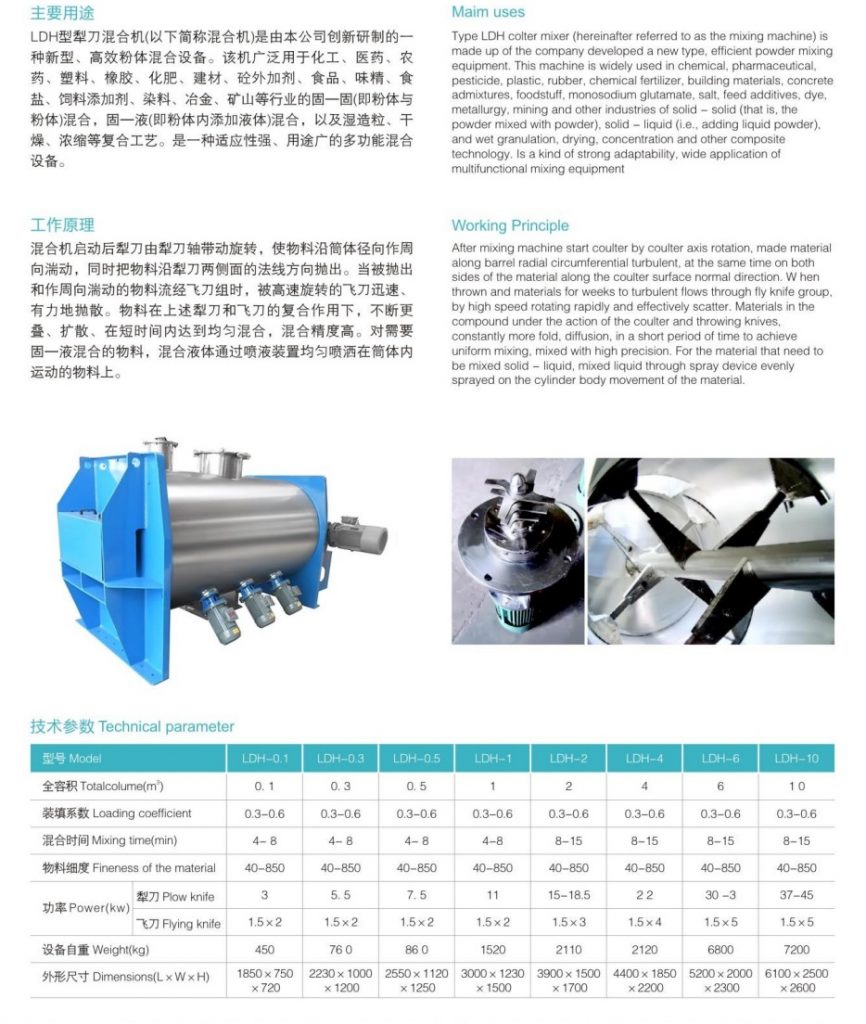

The Ploughshare Mixer, also known as a ploughshare, plow, or plough mixer, is engineered for heavy-duty blending, catering to both dry and wet materials. This mixer features a cylindrical drum housing plough-shaped mixing elements mounted on a horizontal shaft, generating a mechanical fluidized bed mixing action.

It finds extensive use in mixing chemical materials, pigments, pharmaceutical substances, and feedstock, especially for fragile solid grains. Notably, it excels at blending materials with substantial differences in grain size and density in a remarkably short time.

The Plough Shear Mixer is versatile and can be adapted for various industrial processes, including mixing, drying, reacting, moistening/coating, sterilization, granulation, and emulsification.

In this mixer, plough-shaped shovels mounted on a central shaft easily penetrate dense powder masses within a cylindrical drum or vessel. The shaft is positioned horizontally. The size, number, positioning, geometric shape, and peripheral speed of these mixing elements play a crucial role in achieving optimal mixing.

The shuffling action of the mixture is primarily achieved through the broader end of the shovels. This penetration, followed by rapid agitation by the specially designed blades, results in a homogeneous powder mass, both in its dry and wet stages. Subsequently, a centrally mounted chopper may be engaged to produce uniform wet granules.

Efficiently discharged from the bottom of the mixing drum through a flush-fit discharge port, the mixed homogeneous mass is ready for further processing. Our machines cater to a wide range of industries, ensuring quality and consistency in the processing of various materials.

Processed Material with our machines for below industries :

- Plough Shear Mixer for Foods

- Plough Shear Mixer for Starch

- Flavoring Plough Shear Mixer

- Coffee Plough Shear Mixer

- Chocolate Plough Shear Mixer

- Nutraceuticals Plough Shear Mixer

- Cosmetic Plough Shear Mixer

- Pharmaceuticals Plough Shear Mixer

- Detergent Plough Shear Mixer

- Soaps Plough Shear Mixer

- Metal Powders Plough Shear Mixer

- Minerals Plough Shear Mixer

- Friction Material Plough Shear Mixer

- Ceramics Plough Shear Mixer

- Agricultural Chemicals Plough Shear Mixer

- Cement and Sand Plough Shear Mixer

- Carbon black Plough Shear Mixer

- Fire retardants Plough Shear Mixer

Ploughshare Mixer Working Principle:

The ZGH vertical high-speed mixer is comprised of a bottom feed pulp and a high-speed crushing pulp. The bottom material is consistently fed upwards along the cylinder’s wall. Simultaneously, the high-speed crushing leaf slurry efficiently pulverizes the material sent by the leaf slurry, creating a vortex-like material circulation. This rapid process achieves the goal of evenly mixing the materials in a remarkably short time.

Ploughshare Mixer Design:

Features of High Speed Mixer:

| Business Type: | Manufacturer/Factory | Main Products: | Mill, grinder, granulator, mixer, Crushing Equipment |

| Number of Employees: | 100 | Year of Establishment: | 2014.05 |

| Production Capacity | 5000Set/Year | After-sales Service: | Technical Support; on-line teach lessons |

| R&D Capacity: | ODM, OEM | Annual Output Value: | US$5 Million – US$10 Million |

| No. of R&D Staff: | 5 | No. of Production Lines: | 6 |

LK Mixer is a professional manufacturer for grinder, mixer and pulverizer. These machines are widely used in pharmaceutical, cosmetic, health care products and chemical industries. Our main product including granulating machine, grinder, mixer, dryer, etc. All mechanical products in accordance with the China GMP design requirements. And also we have other certifications such as CE, UL for motors.

Business Philosophy

“Quality is the main policy of sales” and “integrity is the principle of success” are the business philosophy of our people. We carry out one-year warranty, lifelong maintenance service, with technical consultation, with material test machine and other services, and long-term supply of equipment. Welcome new and old customers to negotiate cooperation!

Certifications:

Electric Cabinet with UL Certification

Cyclone Processor and Motors:

Spare Parts:

Small Machine Packing:

Small machine packed with export fumigation-free wooden cases, goes with bulk shipment or in container.

When packing small machines for sea shipment, it is important to take measures to ensure that the machines are protected from damage during transit. Here are some general steps that a manufacturer may follow when packing small machines for sea shipment:

- Clean and dry the machine: Before packing, the machine should be thoroughly cleaned and dried to prevent any moisture or debris from causing damage during transit.

- Disassemble the machine: If possible, the machine should be disassembled into its component parts to reduce its overall size and make it easier to pack.

- Wrap the machine in protective material: The machine should be wrapped in a layer of protective material, such as bubble wrap or foam, to protect it from scratches and impact during transit.

- Place the machine in a sturdy box: The wrapped machine should then be placed in a sturdy box that is appropriate for the size and weight of the machine. The box should be made of durable material, such as corrugated cardboard or plywood, and should be able to withstand the rigors of sea transit.

- Add packing material: The box should be filled with packing material, such as packing peanuts or air pillows, to provide cushioning and prevent the machine from shifting during transit.

- Seal the box: The box should be securely sealed with high-quality packing tape to prevent it from opening during transit.

- Label the box: The box should be clearly labeled with the machine’s name, weight, and any other relevant information, as well as the destination address and contact information.

Overall, the goal is to pack the small machine in a way that will protect it from damage during transit and ensure that it arrives at its destination in good condition. It is important to follow proper packing procedures and use high-quality packing materials to minimize the risk of damage during sea shipment.

Large Machine Packing:

Packing a large machine for sea shipment can be a complex and challenging task. However, with careful planning and attention to detail, it is possible to pack a large machine for sea shipment in a way that will ensure that it arrives at its destination in good condition. Here are some general steps that a manufacturer may follow when packing up a large machine for sea shipment:

- Clean and prepare the machine: Before packing, the machine should be thoroughly cleaned and prepared. All fluids, such as oil or coolant, should be drained, and any loose or detachable parts should be removed.

- Disassemble the machine: If possible, the machine should be disassembled into its component parts to reduce its overall size and make it easier to pack. Each part should be carefully labeled and numbered to ensure that it can be easily reassembled at the destination.

- Protect delicate parts: Delicate or fragile parts should be wrapped in protective material, such as bubble wrap or foam, to protect them from damage during transit.

- Build a custom crate: A custom crate should be built around the machine to provide a secure and sturdy enclosure. The crate should be made of durable material, such as plywood, and should be designed to fit the machine snugly. The crate should also include braces or supports to prevent the machine from shifting during transit.

- Add cushioning material: The crate should be filled with cushioning material, such as packing peanuts or air pillows, to provide extra protection and prevent the machine from moving or shifting during transit.

- Securely fasten the machine: The machine should be securely fastened to the crate to prevent it from moving or shifting during transit. This may involve using straps, bolts, or other fasteners to hold the machine in place.

- Seal and label the crate: The crate should be securely sealed with high-quality packing tape, and should be clearly labeled with the machine’s name, weight, and any other relevant information. The destination address and contact information should also be clearly marked on the crate.

Overall, packing a large machine for sea shipment requires careful planning and attention to detail. It is important to use high-quality materials and follow proper packing procedures to ensure that the machine arrives at its destination in good condition. A professional packing and shipping company may be consulted to ensure that the machine is properly packed and prepared for sea shipment.

Customer Side Machine Groups Showcase Videos:

Dust Collector Shipment

Shipment – Packing Method

Two Large Industrial Grinder Ready to Ship

Domestic Shipment Show Case:

Installation Layout:

Maintenance and Safety Measures

Universal Grinder Youtube Video (See More)

About LKMixer

LKMixer is a professional manufacturer for fertilizer production line, grinder, mixer and granulator, shredder. These machines are widely used in food, pharmaceutical, cosmetic, health care products and chemical industries. The Food materials like Peanut, mushroom, seeds, potato, bean, tobacco, salt, cannabis, tea, Sugar, corn, Coffee, rice, pepper, grain as so on. Grinders have many types such as Pulse Dust Grinder which suitable for zero pollution environment, Turbine Mill which is suitable for coffee bean, 12-120mesh all can meet, Ultrafine Grinding Mill covers 80-200mesh, and also Winnowing Dust Grinder or other grinding machines like SF Hammer. Welcome to contact us for details. Contact us for more information. Proposal, catalog, quotation. Mobile/WhatsApp: +86 18019763531 Tel: +86 21 66037855 Email: sales@lkmixer.com