DLG Screw Mixer

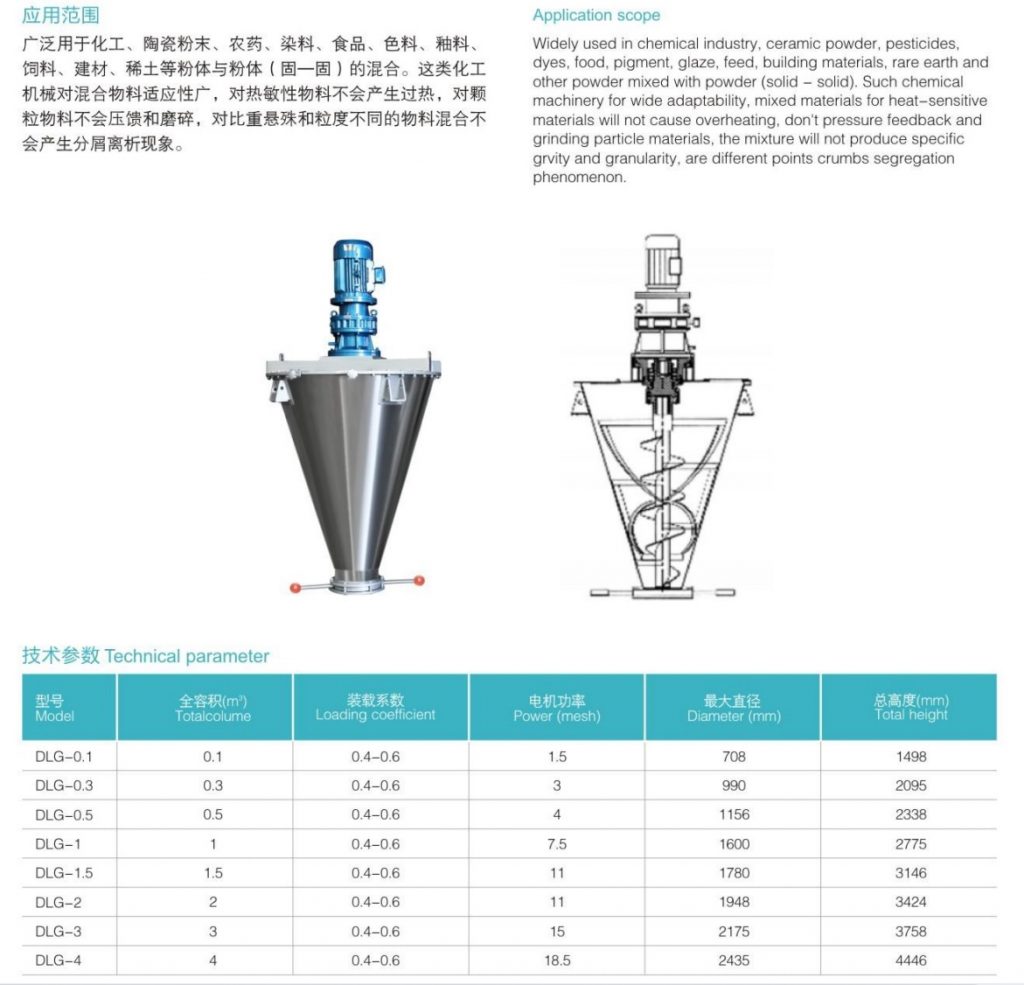

DLG Conical Screw Mixer Single Spiral

- Suitable Material: Powder& Powder; Solid & Solid;

- Mixed amount/bach KG : 0.1~4m³;

- Total Power: 1.5~18.5 KW

- Loading co-efficient: 0.4~0.6;

- Application:

- Widely used in chemica industry ceramic powder pestcides, dyes, food,pigment,glaze, feed,buiding materlas. rare earth and othar powder mixad with powder(solid – solid).Such chemical machinery for wide adaptability mxed maerials for heat-sensitive materials will not cause overheating don’t pressure feedback and grnding paricle materials the mixture wll not produce specific grvity and granularity are dfferent pointscrumbs segregation phenomenon.

arameters of Conical Screw Mixer:

:

| Model | Capacity(m³) | Loading Co efficient | Power | Diameter(mm) | Height(mm) |

| DLG-0.1 | 0.1 | 0.4~0.6 | 1.5 | 708 | 1498 |

| DLG-0.3 | 0.3 | 0.4~0.6 | 3 | 990 | 2095 |

| DLG-0.5 | 0.5 | 0.4~0.6 | 4 | 1156 | 2338 |

| DLG-1 | 1 | 0.4~0.6 | 7.5 | 1600 | 2775 |

| DLG-1.5 | 1.5 | 0.4~0.6 | 11 | 1780 | 3146 |

| DLG-2 | 2 | 0.4~0.6 | 11 | 1948 | 3424 |

| DLG-3 | 3 | 0.4~0.6 | 15 | 2175 | 3758 |

| DLG-4 | 4 | 0.4~0.6 | 18.5 | 2435 | 4446 |

What is Conical Screw Mixer:

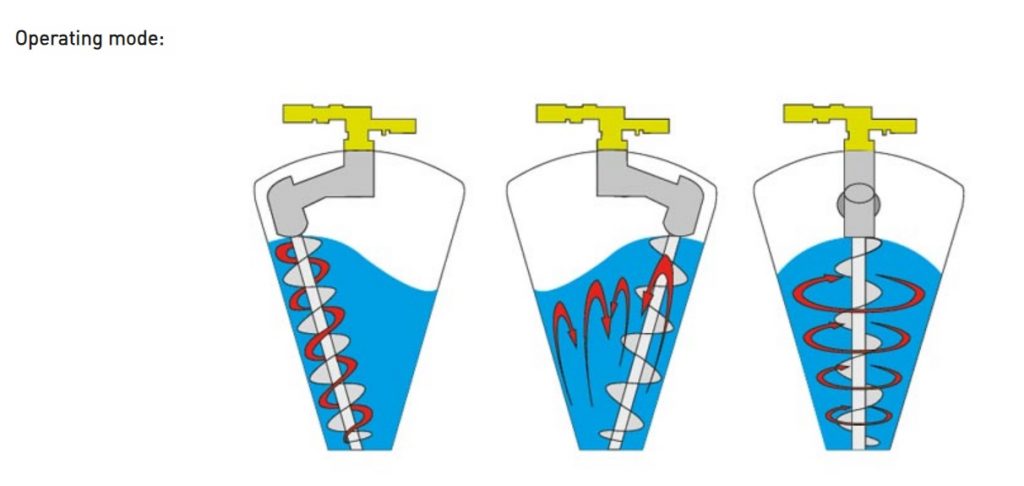

Conical screw mixers are a marvel of engineering, employing a rotating screw that gracefully spirals around the edge of a conical hopper. The magic happens as the screw elegantly lifts solid materials from the hopper’s base to its summit. From there, gravity gracefully guides the mixture back into the screw’s embrace. But the real artistry lies in the mixing process that unfolds around this open screw.

Picture this: as the solid particles are transported by the screw, they exit at different levels, only to be swiftly replaced by other materials at that same level. It’s a symphony of movement, where the screw’s shearing action choreographs an intimate dance between the various components, resulting in a harmonious blend.

The key to this elegant operation is the conical hopper, which creates a unique velocity profile as it feeds the screw, fostering a significant mixing action. This action reaches its zenith when the solids glide along the conical hopper walls.

When it comes to selecting conical screw mixers, several crucial factors come into play. The choice depends on media type (liquid, liquid-solid, or powder), capacity (specified in gallons), feed rate (in gallons per minute), and motor speed (with considerations like accuracy and motor power). Operating conditions typically involve batch processing, overhead mounting, and top-entry placement. It’s also essential to factor in operating temperature and pressure.

Delving into available features, some conical screw mixers come equipped with internal heating or cooling elements, while others offer programmability for flexibility in handling various materials and ranges. Display options vary from analog (with dials or indicator lights) to digital (numerical displays) and even video displays using technologies like cathode ray tubes (CRTs) or liquid-crystal displays (LCDs).

Conical screw mixers cater to a wide array of applications, including adhesives, chemicals, cosmetics, paints, coatings, and pharmaceutical products. In the realm of chemical processing, you’ll find mixers designed for both general chemical heating and handling corrosive chemicals like acids and solvents. These versatile mixers are also essential in water and wastewater treatment, contributing to processes such as mixing carbon slurry and lime slurry.

In essence, conical screw mixers are a testament to precision engineering, seamlessly blending a diverse range of materials and serving as invaluable tools in various industries.

The Innovative Conical Screw Mixer: Gentle Mixing, Maximum Efficiency

The conical screw mixer operates on a time-tested principle where a rotating mixing screw, guided by an orbital arm, moves closely along the vessel’s wall. This ingenious design maintains a delicate yet highly effective mixing and product displacement process. It’s an ideal choice for handling demanding bulk solids found in pharmaceutical, chemical, and food industries, guaranteeing a unique and gentle mixing experience.

Conical Screw Mixer Types:

Application of conical screw mixer:

Here are some key advantages that benefit our customers:

- Efficient and Gentle Mixing: Despite its small drive power, this mixer excels without causing mechanical or thermal damage to your products due to wear and attrition. It delivers a high mixing yield, achieving perfect blending and optimal mixing times.

- Versatile Suitability: This mixer is uniquely suited for a wide range of industrial products, regardless of differences in density, particle size, shape, proportions, and more. It ensures a homogeneous blend without any risk of segregation, accommodating various product characteristics.

- Flexible and Adaptable: With the ability to operate at partial loads ranging from 10% to 100%, it offers maximum flexibility. This makes it an excellent choice for multi-product applications and scenarios where product volumes frequently change.

- Efficient Product Discharge: Enjoy the convenience of central, unrestricted, and residue-free product discharge. The mixer ensures a smooth, homogeneous product flow, minimizing waste and maximizing efficiency.

- Easy to Clean: Cleaning is a breeze with this mixer. It offers good cleanability, ensuring a complete and residue-free drainage of cleaning fluids. Keeping your equipment clean and ready for the next batch is hassle-free.

In conclusion, the conical screw mixer combines innovation and efficiency to provide a superior mixing solution for various industries. It’s designed to handle even the most challenging bulk solids, delivering exceptional results while maintaining product integrity and quality.

| Business Type: | Manufacturer/Factory | Main Products: | Mill, grinder, granulator, mixer, Crushing Equipment |

| Number of Employees: | 100 | Year of Establishment: | 2014.05 |

| Production Capacity | 5000Set/Year | After-sales Service: | Technical Support; on-line teach lessons |

| R&D Capacity: | ODM, OEM | Annual Output Value: | US$5 Million – US$10 Million |

| No. of R&D Staff: | 5 | No. of Production Lines: | 6 |

LK Mixer is a professional manufacturer for grinder, mixer and pulverizer. These machines are widely used in pharmaceutical, cosmetic, health care products and chemical industries. Our main product including granulating machine, grinder, mixer, dryer, etc. All mechanical products in accordance with the China GMP design requirements. And also we have other certifications such as CE, UL for motors.

Business Philosophy

“Quality is the main policy of sales” and “integrity is the principle of success” are the business philosophy of our people. We carry out one-year warranty, lifelong maintenance service, with technical consultation, with material test machine and other services, and long-term supply of equipment. Welcome new and old customers to negotiate cooperation!

Certifications:

Electric Cabinet with UL Certification

Cyclone Processor and Motors:

Spare Parts:

Small Machine Packing:

Small machine packed with export fumigation-free wooden cases, goes with bulk shipment or in container.

When packing small machines for sea shipment, it is important to take measures to ensure that the machines are protected from damage during transit. Here are some general steps that a manufacturer may follow when packing small machines for sea shipment:

- Clean and dry the machine: Before packing, the machine should be thoroughly cleaned and dried to prevent any moisture or debris from causing damage during transit.

- Disassemble the machine: If possible, the machine should be disassembled into its component parts to reduce its overall size and make it easier to pack.

- Wrap the machine in protective material: The machine should be wrapped in a layer of protective material, such as bubble wrap or foam, to protect it from scratches and impact during transit.

- Place the machine in a sturdy box: The wrapped machine should then be placed in a sturdy box that is appropriate for the size and weight of the machine. The box should be made of durable material, such as corrugated cardboard or plywood, and should be able to withstand the rigors of sea transit.

- Add packing material: The box should be filled with packing material, such as packing peanuts or air pillows, to provide cushioning and prevent the machine from shifting during transit.

- Seal the box: The box should be securely sealed with high-quality packing tape to prevent it from opening during transit.

- Label the box: The box should be clearly labeled with the machine’s name, weight, and any other relevant information, as well as the destination address and contact information.

Overall, the goal is to pack the small machine in a way that will protect it from damage during transit and ensure that it arrives at its destination in good condition. It is important to follow proper packing procedures and use high-quality packing materials to minimize the risk of damage during sea shipment.

Large Machine Packing:

Packing a large machine for sea shipment can be a complex and challenging task. However, with careful planning and attention to detail, it is possible to pack a large machine for sea shipment in a way that will ensure that it arrives at its destination in good condition. Here are some general steps that a manufacturer may follow when packing up a large machine for sea shipment:

- Clean and prepare the machine: Before packing, the machine should be thoroughly cleaned and prepared. All fluids, such as oil or coolant, should be drained, and any loose or detachable parts should be removed.

- Disassemble the machine: If possible, the machine should be disassembled into its component parts to reduce its overall size and make it easier to pack. Each part should be carefully labeled and numbered to ensure that it can be easily reassembled at the destination.

- Protect delicate parts: Delicate or fragile parts should be wrapped in protective material, such as bubble wrap or foam, to protect them from damage during transit.

- Build a custom crate: A custom crate should be built around the machine to provide a secure and sturdy enclosure. The crate should be made of durable material, such as plywood, and should be designed to fit the machine snugly. The crate should also include braces or supports to prevent the machine from shifting during transit.

- Add cushioning material: The crate should be filled with cushioning material, such as packing peanuts or air pillows, to provide extra protection and prevent the machine from moving or shifting during transit.

- Securely fasten the machine: The machine should be securely fastened to the crate to prevent it from moving or shifting during transit. This may involve using straps, bolts, or other fasteners to hold the machine in place.

- Seal and label the crate: The crate should be securely sealed with high-quality packing tape, and should be clearly labeled with the machine’s name, weight, and any other relevant information. The destination address and contact information should also be clearly marked on the crate.

Overall, packing a large machine for sea shipment requires careful planning and attention to detail. It is important to use high-quality materials and follow proper packing procedures to ensure that the machine arrives at its destination in good condition. A professional packing and shipping company may be consulted to ensure that the machine is properly packed and prepared for sea shipment.

Customer Side Machine Groups Showcase Videos:

Dust Collector Shipment

Shipment – Packing Method

Two Large Industrial Grinder Ready to Ship

Domestic Shipment Show Case:

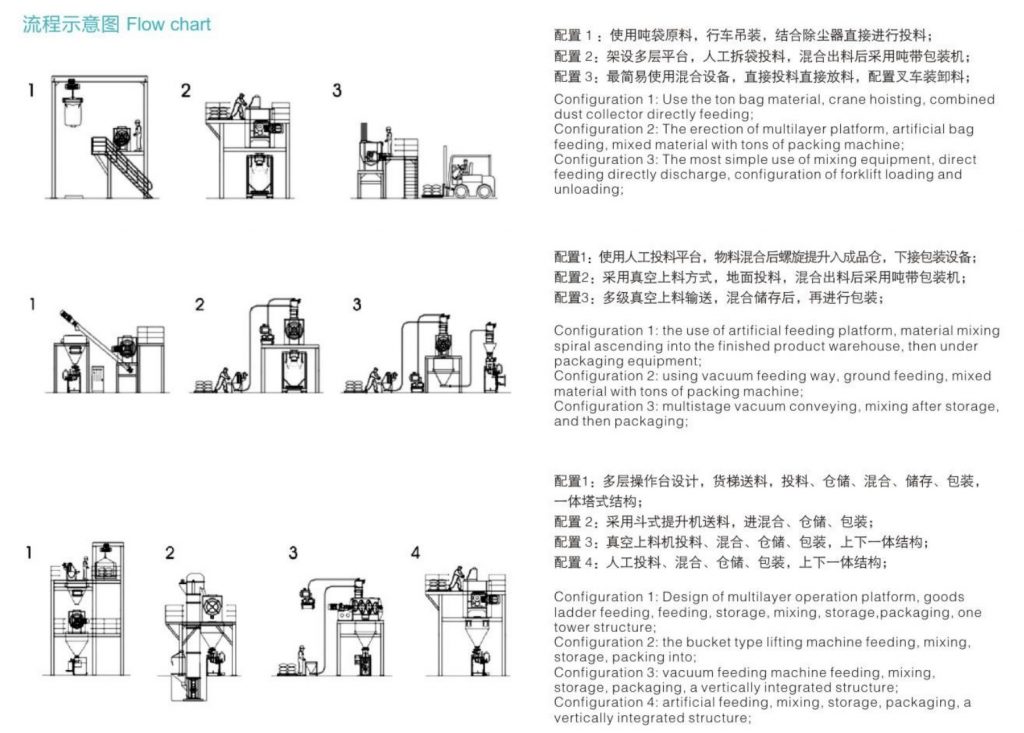

Installation Layout:

Maintenance and Safety Measures

Proper maintenance practices for the machine

Proper maintenance practices are essential for ensuring the efficient and safe operation of a universal grinder. Here are some maintenance practices that should be followed:

- Regular cleaning – The machine should be cleaned regularly to remove any debris, dust, or coolant that may accumulate on the machine’s surfaces. This can be done using a soft brush, air hose, or a cleaning solution.

- Lubrication – The machine’s moving parts should be lubricated regularly to reduce friction and wear. The manufacturer’s recommendations for lubrication intervals and types should be followed.

- Inspection – The machine should be inspected regularly for any signs of wear, damage, or misalignment. Any issues should be addressed immediately to prevent further damage or safety hazards.

- Replacement of worn or damaged parts – Worn or damaged parts should be replaced immediately with genuine parts from the manufacturer.

- Calibration – The machine should be calibrated regularly to ensure that it is operating within the specified tolerances and accuracy.

- Operator training – Proper operator training is essential for ensuring the safe and efficient operation of the machine. Operators should be trained on the proper operation, maintenance, and safety procedures for the machine.

- Record keeping – A maintenance log should be kept to track the machine’s maintenance history, including cleaning, lubrication, inspection, and repairs. This can help identify any trends or issues that need to be addressed.

Following these maintenance practices can help ensure the safe and efficient operation of a universal grinder, prolong its lifespan, and reduce the risk of downtime and costly repairs.

Safety measures for operators and workers

Safety measures for operators and workers are crucial when using a universal grinder. Here are some safety measures that should be followed:

- Personal protective equipment (PPE) – Operators and workers should wear appropriate PPE, including safety glasses, hearing protection, gloves, and safety shoes.

- Machine guards – The machine should be equipped with proper machine guards to prevent access to the grinding wheel during operation. The guards should be in good condition and properly installed.

- Lockout/tagout procedures – Lockout/tagout procedures should be followed to ensure that the machine is not accidentally started or energized during maintenance or repair.

- Training – Operators and workers should receive proper training on the safe operation of the machine, including the use of PPE, machine guards, and lockout/tagout procedures.

- Inspection – The machine should be inspected regularly for any signs of wear, damage, or misalignment that may pose a safety hazard.

- Proper use of grinding wheels – Operators should ensure that the grinding wheel is properly installed, dressed, and aligned. The grinding wheel should not be overloaded or forced into the material being ground.

- Proper handling of coolant – If coolant is used, operators should ensure that it is properly mixed, applied, and contained. Coolant should not be allowed to accumulate on the floor, as it can create a slipping hazard.

- Emergency procedures – Emergency procedures should be established and communicated to all operators and workers in case of an accident or injury.

Following these safety measures can help prevent accidents and injuries when using a universal grinder. It is important to prioritize safety and ensure that all operators and workers are trained and informed about the potential hazards of the machine.

Features of Ribbon Blender:

Our equipment comes in two distinct shapes to suit different volume needs: U-shape, ideal for low to medium capacity operations with a single shaft, and W-shape, designed for large to mega-volume operations with double shafts.

To maintain the highest standards of hygiene, all components that come into contact with materials are made of stainless steel 316. We’ve taken extra precautions by mounting bearings on lanterns outside the mixing zone to prevent any cross-contamination.

Our design also simplifies material handling by offering a convenient side discharge feature for processed materials. Rest assured, our equipment complies with all cGMP/cGEP standards to meet industry requirements.

To ensure even better control over cross-contamination, we’ve incorporated air purges on the side entry seals. Additionally, our continuous ribbon design ensures thorough discharge of the finished product.

For a quieter working environment and reduced maintenance needs, our power transmission is belt-driven. For those handling fragile materials, we offer a paddle-style agitator option instead of a ribbon, providing gentler blending.

Our equipment’s capacity ranges from 125 liters to 8,400 liters, and we can even provide larger volumes of up to 20,000 liters if needed.

Universal Grinder Youtube Video (See More)

About LKMixer

LKMixer is a professional manufacturer for fertilizer production line, grinder, mixer and granulator, shredder. These machines are widely used in food, pharmaceutical, cosmetic, health care products and chemical industries. The Food materials like Peanut, mushroom, seeds, potato, bean, tobacco, salt, cannabis, tea, Sugar, corn, Coffee, rice, pepper, grain as so on. Grinders have many types such as Pulse Dust Grinder which suitable for zero pollution environment, Turbine Mill which is suitable for coffee bean, 12-120mesh all can meet, Ultrafine Grinding Mill covers 80-200mesh, and also Winnowing Dust Grinder or other grinding machines like SF Hammer. Welcome to contact us for details. Contact us for more information. Proposal, catalog, quotation. Mobile/WhatsApp: +86 18019763531 Tel: +86 21 66037855 Email: sales@lkmixer.com