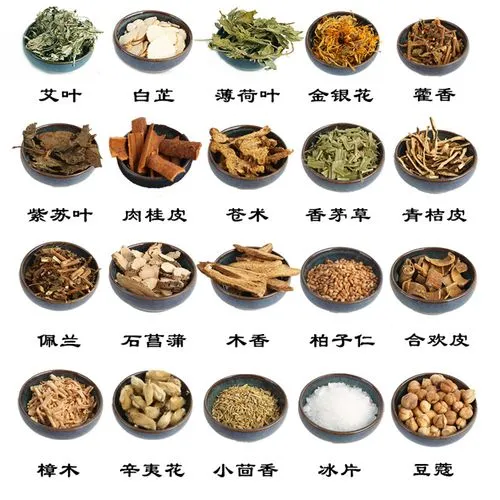

The principle of ultra-fine grinding technology and the purpose and significance of Chinese medicine processing

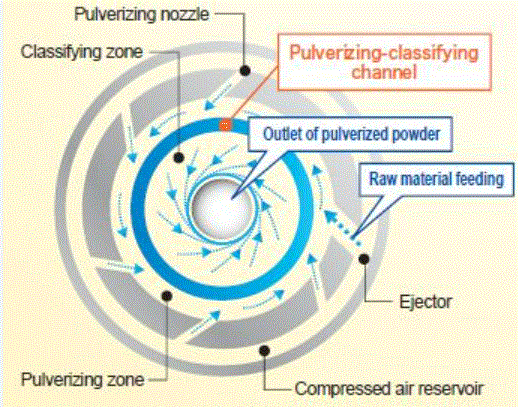

The purpose of ultra-fine pulverization is mainly to use some characteristics of micro-powder, such as surface accumulation, surface energy, high surface activity, and the drug is easily absorbed by the human body after ultra-fine pulverization, enhancing co-efficacy, and improving the preparation process.

(1) Enhance the absorption of radioactive components in the body

Life medicine tree is divided into three categories: plant medicine, animal medicine and mineral medicine. The main efficacy of animal medicine and coffin medicine in addition to medicine into Division of the normal treatment of the symptoms of intra-cellular and inter-cellular, 11 mainly intracellular.

In addition to the active ingredients, plant medicinal materials contain a large number of 1t other components, such as protein, fat, starch, resin, cooked liquid, Pectin, good quality and structural substances (such as cellulose, school, stone cells, etc.). For the ordinary method of grinding, in powder form;

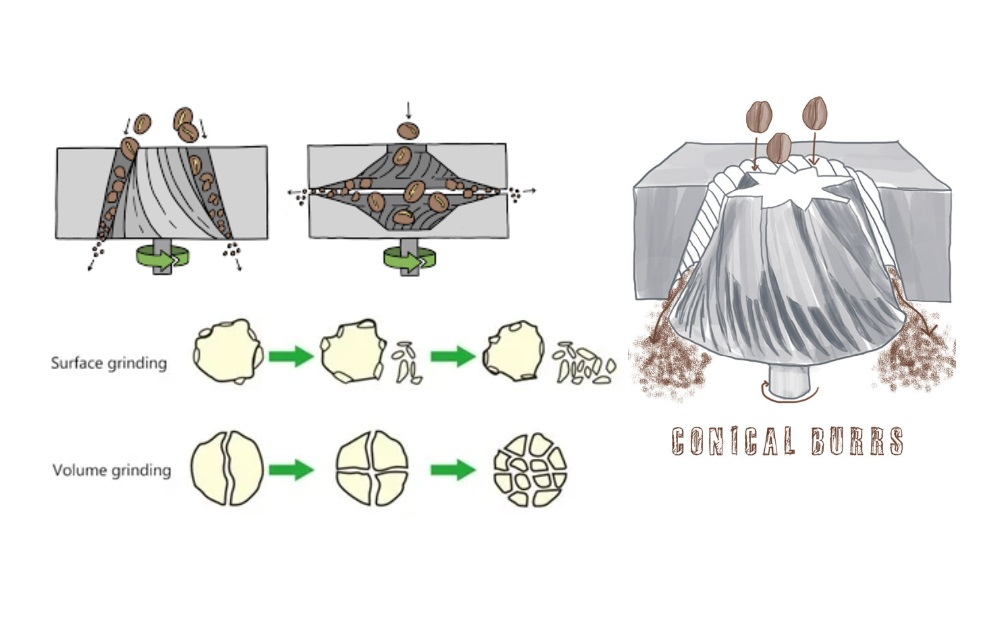

Most of the effective components of the Chinese medicine are wrapped in unbroken cells, and the drug powder enters the gastrointestinal tract;

The molecular weight of the active component in the cell is generally much smaller than that of the inactive component, so it can be gradually released through the cell wall and then;

Metastasizes or dissolves into small gastric and intestinal fluid and is absorbed out of the small intestine. When the drug particles are coarse, the cells are often several or dozens of ‘together, and the active ingredients in the cell have to pass through many cell tissues to be released, so the drug weighing speed is very slow, the residence time of the drug in the body is limited, and the absorption amount of the active ingredients in the case of very low drug release speed is also very low: at the same time, due to the coarse particles, The amount of adsorbed in the small intestinal wall is also less, and the amount of absorption is also less. On the other hand, due to the large drug particle size and low mixing uniformity, drug components with different properties will vary in absorption rate and degree due to differences in fineness, cell expansion rate, migration rate from cell wall, and absorption to intestinal wall, thus affecting the efficacy of compound drugs.

After the plant medicinal materials were crushed by ultramicro, the cell wall of most of the cells was broken, and the apricot effect components in the cells were automatically connected to the drug administration site without the cell wall disintegration. On the one hand, due to the small particle size of the micro-powder drug, it is easy to adsorb in the small intestinal wall L and be absorbed by small intestinal silicon, greatly improving the absorption rate of the active ingredient: on the other hand, the contact area between the micro-powder and the drug administration site is large, extending the retention time of the drug in the body, and the absorption amount of the drug is also significantly increased.

Read more about relative blog

In addition, experts proposed that the medicinal materials of the mill have a homogenization effect in the process of cell-level crushing, and that most small medicines usually contain water, oily ingredients and volatile oils, and under the action of high intensity impact and thistle cutting force, when the cell wall is broken, After migrating from the cell, these components make the surface of the tiny particles in a semi-wetting state and under the action of some surface active substances in medicinal materials, the hydrophilic components are friendly, resulting in emulsification and homogenization mixing to achieve a “homogeneous state”. At this time, particles form semi-stable “particle clusters” (or “micro-particles”) between particles, and each “particle cluster” contains the same proportion of the drug component. The small volatile components of oil cells are also “homogenized” when the cells are priced. This kind of “homogenized” Chinese medicine micro-toughness into the intestinal tract quickly dispersed evenly, the water, self and hair components in the original composition ratio of synchronous absorption, compared with the ordinary powder pulverized wood in the body absorption rate and absorption degree greatly improved. Due to the absorption and expansion of fiber, after micro-pulverized medicinal materials powder, the co-fiber has reached a super-fine state, the swelling particles have greatly increased, and the effect of medicinal dressing, the hyperactive gastrointestinal tract can be rapidly disintegrated to promote the release and absorption of the active ingredients of drugs.

Most of the active components of animal traditional Chinese medicine exist in the cell in the form of macromolecules. Before extraction. The work content medicine group pounding machine is adopted to improve the ground commonly, its purpose is to destroy the cell membrane, improve the extraction yield of active ingredients. Under normal circumstances, the finer the cell is broken, the more intense the extraction effect, the large cell structure of mineral Chinese medicine, the effect of grinding fineness on its efficacy and bioavailability is the same as that of insoluble chemical drugs. The dissolution rate of the drug is inversely proportional to the particle size of the drug, and the surface area of the spoon is proportional, so the smaller the drug particles are. The larger the specific surface area, the greater the dissolution rate, the faster the absorption rate and the higher the bio-utilization zone.

(2) Retain the properties and functions of traditional Chinese medicine

Traditional Chinese medicine emphasizes compatibility, and compound force and application are its characteristics. According to the various factors affecting the body, the various nail effect components contained in TCM compounds can have an integrated adjustment effect on the body through multi-link, multi-level and multi-target, and adapt to the characteristics of the diversity and complexity of the body lesions. The active ingredients of traditional Chinese medicine are applied in the form of micro powder, and the current components and the common pharma-codynamic substance base are retained.

It maintains the attributes and functional indications of traditional Chinese medicine, reflects the characteristics of TCM syndrome differentiation and overall treatment, and is better handled.

The relationship between the application of modern science and technology and inheriting the inherent characteristics of traditional small drugs in the research and development of modern drugs.

(3) Develop the traditional crushing force method and meet the needs of the modernization of Chinese medicine

The traditional crushing method of towel medicine is cutting, ramming, grinding, grinding, sifting, etc. The means are backward, the equipment is obsolete, the efficiency is low, the level is low, the fineness of the general processing is 80 to 120 mesh, less to 200 mesh, relative to the extraction, separation and drying, molding and other new technology application, remote with a “: the pace of development of traditional Chinese medicine preparation technology, can not meet the needs of the modernization of 11 pharmaceutical preparations. The introduction of ultra-fine grinding technology is not only the development of traditional Chinese medicine grinding method, but also the inevitable requirement of Chinese medicine modernization.

4) Develop new formulations of traditional Chinese medicine

Some precious Chinese medicinal materials such as pearl, pilfering incense, deer, ginseng, cordyceps, etc., can be made directly after ultra-fine grinding ngB powder, capsule, micro Nie and other benefits. It can also be used to make topical agents with good dispersibility, increased permeability and small irritants after micro-pulverization of traditional Chinese medicine, and to make trans-dermal preparations after mixing with appropriate substrates, or to make targeted preparations with some drug spoon ultra-fine magnetic powders with good efficacy and large adverse reactions. In addition, the traditional Chinese medicine powder used with medicine and

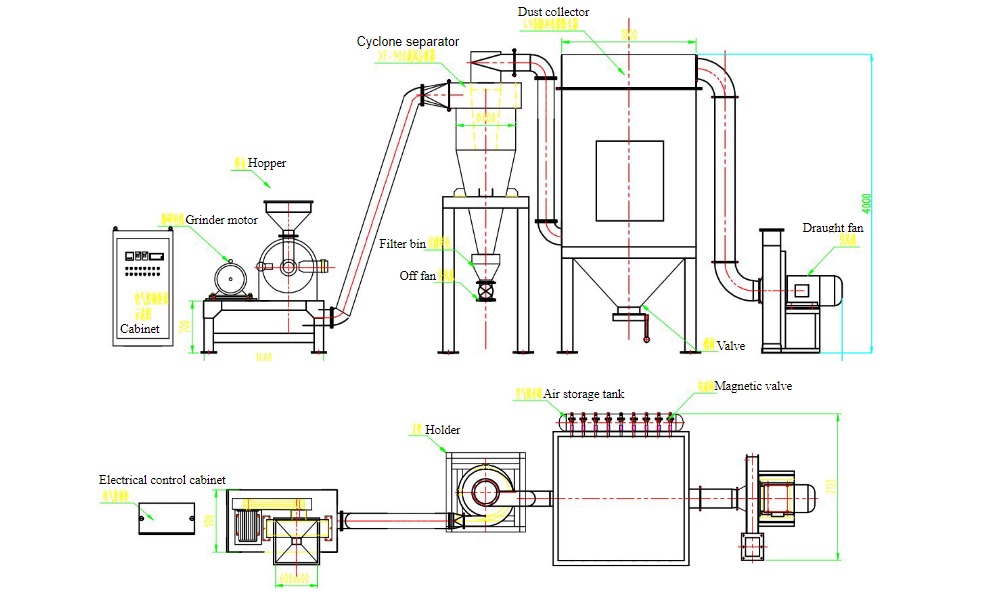

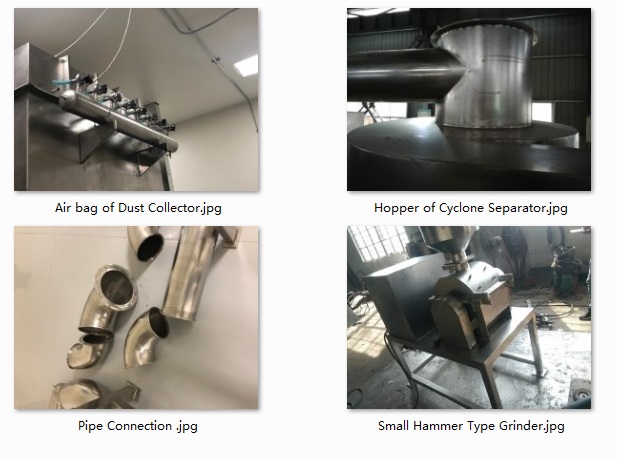

Medicine Producing Process Flow:

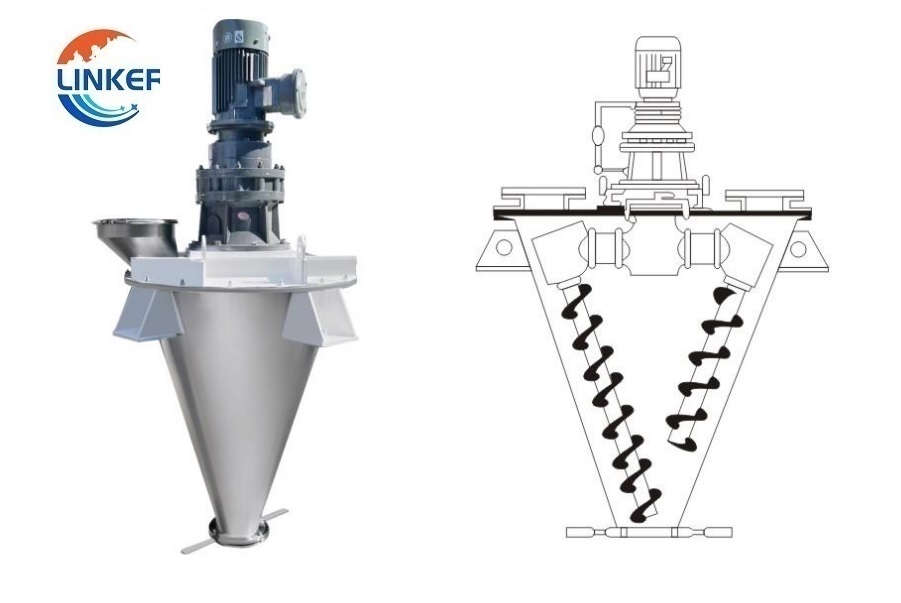

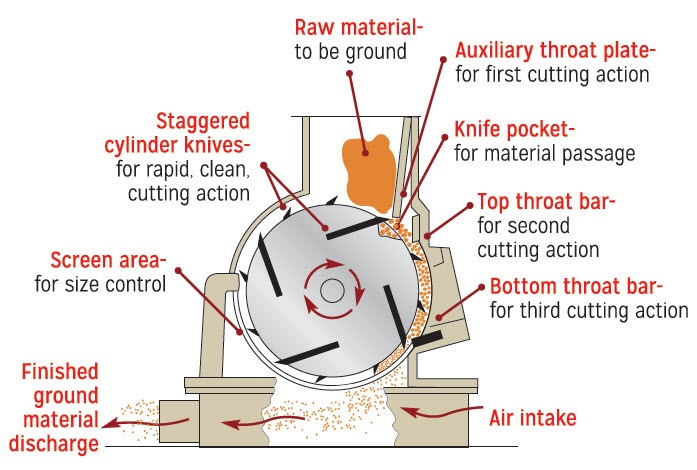

Ultrafine grinding is one of the very key procedure in whole production line. It depends how many mesh that customer need to produce. That’s to say this machine can decide what kind of material will get finally before mxing.

Coarse Crusher Machine —>Grinding Machine —> Vibrating Table Sifter Machine—>Mixing Machine—>Packing Machine —> (Printed Packaging Film Roll or bags ) —> Filling, sealing machine, capping and Labeling Machine —>Pack into Box.

About LKMixer

LKMixer is a professional manufacturer for fertilizer production line, grinder, mixer and granulator, shredder. These machines are widely used in food, pharmaceutical, cosmetic, health care products and chemical industries. The Food materials like Peanut, mushroom, seeds, potato, bean, tobacco, salt, cannabis, tea, Sugar, corn, Coffee, rice, pepper, grain as so on. Grinders have many types such as Pulse Dust Grinder which suitable for zero pollution environment, Turbine Mill which is suitable for coffee bean, 12-120mesh all can meet, Ultrafine Grinding Mill covers 80-200mesh, and also Winnowing Dust Grinder or other grinding machines like SF Hammer. Welcome to contact us for details. Contact us for more information. Proposal, catalog, quotation. Mobile/WhatsApp: +86 18019763531 Tel: +86 21 66037855 Email: sales@lkmixer.com

Contact Us

Grinder for Sale:

Blenders for Sale:

FAQ(Click and See More)

Why Choose Us?

We have 20 years manufacturing experiences; 15600 cubic meters factory area; 5000sets annual capacity; 55 professional engineers;

What’s your main maket?

South America: Brazil, Colombia, Peru, Bolivia, Uruguay, Paraguay ;Romania;

USA with UL Certification

Middle East: Saudi, Arabia, Oman, Turkey

Europe: Russia, Australia, Belarus, Ukraine, Poland

Can you support OEM?

– Yes, OEM or ODM. Machine can be customized according to customer detail requirement, including capacity and voltages, motor certifications.

– Drawing and raw materials also can be customized.

What after-sale services?

– 7*24 customer service online;

– 7*24 engineers online services;

– 12 months warranty services.

WHAT kind of MACHINE YOUR COMPANY HAVE?

CAN YOU GIVE ME GUIDE ON OTHER MACHINE ? TO FULL MY PRODUCTION LINE

YES ! Our f have factory build more than 20 years now, we can design and customize whole line, besides of the grinding machine, mixing machine, we can also fully support to provide the washing machine, cutting machine, drying machine, packing machine, filling machine. Though we are not producing these machine, but our brother companies co-work together for over 20 years, we have rich experience in providing you a full effective production line, fully automatically or semi-automatically.

HOW TO VISIT YOUR COMPANY?

Our Factory located in Jiangsu Province, very near to Shanghai, you can fly to Shanghai Pudong Airport, we pick you up and take you by car 2 hours ride, can reach our factory, welcome your visit.

WHAT’S YOUR BEFORE & AFTER SERVICE ?

1) Before your purchasing, we need to know your detail request, such as what kind of material you want to grind and mixing, what final product powder or granule you want to reach. Because different material and powder sizes request of different machine to do. We can provide professional advice and rich experience help to choose machine. Most of the products we have already did before for other customer, trail test or run mass production, so we knows which machine is best in performance of grinding and mixing. This is of very importance in helping you choose the right model. We also wish this can help our customer a lot. Even the material we didn’t do before, we will prepare the same material and to do the trail test and send video to you for your reference.

2) One Year guarantee of machine quality. If the machine have problem within one year, we will send you the spare parts to you for replacement, but this not including the damage caused by human causes. We also have 24 hours on line guide for customer, if you have operation difficulty, we will guide by video and on line communication with our engineer for your emergency debug.

3) For small machine, we sell with whole machine, it’s no need to install, and easy to operation, no problems for operation. While for large machine, its’s also not difficult to install with video guideline, but if you need, we can assign our technicians to go abroad, the round ticket, food and residents will be paid by customer.

HOW ABOUT YOUR PAYMENT TERM?

Our payment term is T/T. 50% payment in advance, rest of 50% payment finish before the goods shipped. When we finish the machine production we will do trail test and run the machine take videos for your green light. You pay the rest of 50% payment then.