What is a ribbon blender used for?

Ribbon Blender (Screw Mixer) is a commonly used mixing equipment for the uniform mixing of solid materials with different particle sizes, densities and properties. It is a kind of equipment used for mixing of viscous or cohesive powder particles and mixing of liquid and paste materials added to powder particles. At the same time, due to the characteristics of difficult cleaning of viscous materials, it is suitable for mixing in situations with large output and infrequent replacement of varieties. It has a wide range of uses, applicable to a number of industries and fields, including but not limited to the following:

Ribbon Blender is widely used in chemical, pharmaceutical, food processing, electronics, building materials, metallurgy, biotechnology, polymer materials and other industries, mainly used for powder, granular and viscous material mixing.

- Food processing: Screw belt mixer can be used in food processing industry for mixing and evenly distributing food raw materials, such as mixing powdered and granular raw materials, such as flour, condiments, additives, pharmaceutical raw materials, vegetables, meat, etc. Ribbon mixers can be used to ensure the uniform distribution of food and pharmaceutical ingredients, improving product quality and stability.

- Chemical industry: ribbon mixer is widely used in the chemical industry, for mixing and stirring powder, granular or sticky chemical substances, powder, granular material mixing, drying and processing. It can be used to prepare chemical reaction materials, manufacture coatings, dyes, adhesives, such as fertilizers, pigments, dyes, plastic powders, solvent adhesives, concentrated adhesives, liquid fillers and other materials mixing. The preparation of chemical raw materials requires frequent mixing and reaction, and the ribbon mixer provides an efficient and stable mixing method to ensure product quality, yield and consistency.

- Pharmaceutical industry: In the pharmaceutical industry, the ribbon mixer can be used for the mixing of capsules, oral tablets, granules, etc. The ribbon mixer plays an important role in the pharmaceutical industry for mixing and evenly dispersing pharmaceutical raw materials, excipients and additives, as well as the mixing of capsules, oral tablets, granules, etc. It can ensure the uniformity and consistency of drugs and improve the efficiency and quality of the pharmaceutical process. The advantages of high automation and simple operation help pharmaceutical companies improve production efficiency; At the same time, the fully enclosed structure design can prevent the material from being polluted and ensure the product quality.

- Building materials: ribbon mixer can be used in the building materials industry for mixing and mixing cement, mortar, concrete, gypsum, sand, aggregate and other materials to produce mortar, concrete and other building materials. It can ensure the uniformity and stability of building materials and improve the quality of construction.

- Environmental protection projects: The screw belt mixer is also used in environmental protection projects, for mixing and treating waste, sludge, solid waste treatment and resource recovery in environmental protection projects. It can help to mix waste with other treatment agents to meet the requirements of environmentally friendly treatment. Ribbon mixers are also available. By mixing different kinds of waste, it can realize the resource utilization of waste and reduce the pollution to the environment.

- Cosmetics industry: used for the mixing, mixing, modulation of various cosmetic ingredients.

Ribbon Blender structure features:

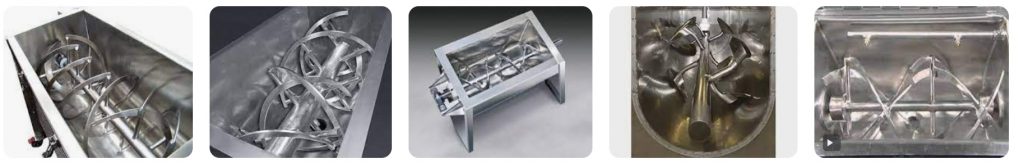

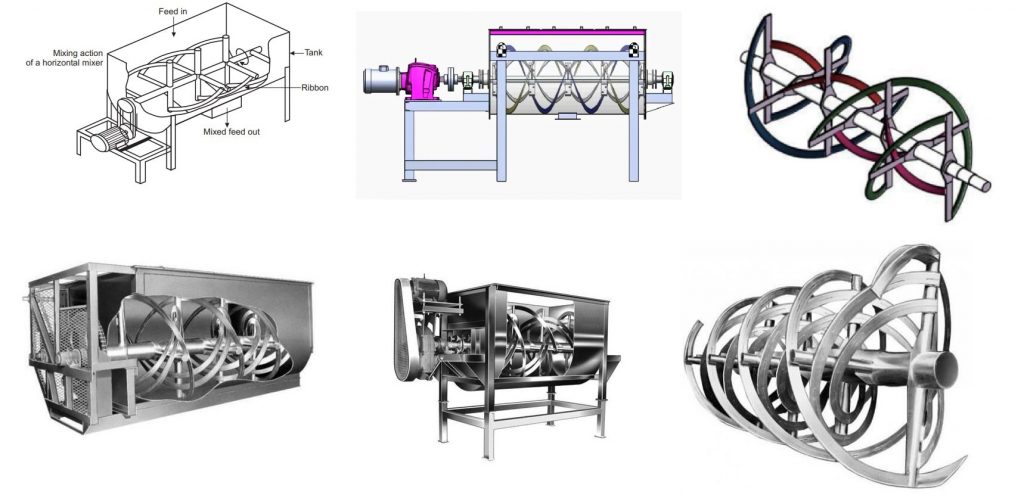

- Composed of U-shaped container, spiral belt mixing blade and transmission parts;

2, U-shaped long cylinder structure, to ensure that the mixed material (powder, semi-fluid) in the cylinder body of the small resistance movement.

3, the positive and negative rotating screw is installed on the same horizontal axis, forming a low power and efficient mixed environment, the spiral blade is generally made of double or three layers, the outer spiral will collect the material from both sides to the center, the inner spiral will transport the material from the center to both sides, which can make the material form more eddy currents in the flow. The mixing speed is accelerated and the mixing uniformity is improved.

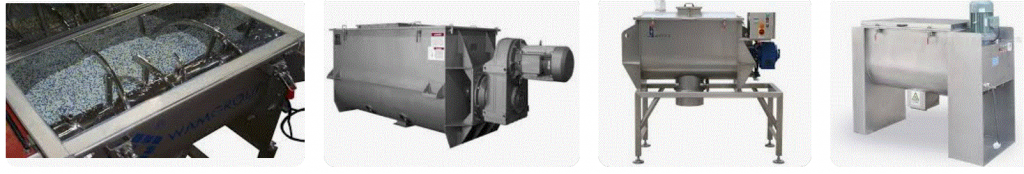

4, horizontal ribbon mixer is a new type of mixing equipment with high efficiency, high uniformity, high loading coefficient, low energy consumption, low pollution and low crushing.

5, the product has a wide range of application, can be powder and powder, powder and liquid mixing, especially can mix paste, thick or large proportion of materials (such as putty, real stone paint, metal powder and other products). It is widely used in pharmaceutical, food, pesticides, dyes, chemicals, plastics, ceramics, coatings, putty, mortar and other fields.

First, the role of the ribbon mixer

Ribbon mixer is a kind of mixing equipment suitable for all kinds of powder and granular materials, mainly used for mixing dry powder, wet powder and viscous liquid paste. The equipment adopts the working principle of double rotation, through the rotation of the inner and outer two helices at different speeds, the material produces a strong cutting, friction and shearing effect in the container, so as to achieve the uniform mixing of the material.

Second, the structural characteristics of the screw belt mixer

The main structure of the ribbon mixer consists of a rotating shaft, a shell, a spiral blade and a bearing. The double-layer spiral blade can realize the relative rotation of multiple layers and increase the mixing effect. The inner wall of the equipment container is smooth without dead corners and easy to clean. At the same time, for the mixing needs of different materials, the equipment can also use blades of different shapes, rotation speeds and positions to meet different mixing effects.

advantage - Good mixing effect

The screw blade design of the screw belt mixer is unique, which can realize the rapid and uniform mixing of materials, and the mixing effect is more thorough. Therefore, the ribbon mixer is the ideal equipment for mixing viscous and easily aggregated materials. - Easy to operate

The screw belt mixer adopts a fully enclosed design, will not produce leakage and flying phenomenon, to ensure the clean and safe working environment; High degree of automation, only a small amount of manual operation is required to successfully complete the production. - Easy maintenance

The internal structure of the screw belt mixer is simple, and the cleaning and maintenance is very convenient, which makes the maintenance cost of the equipment reduced and the service life longer.

Horizontal Ribbon Blender

- The mixing space is in the form of a horizontal U-shaped drum, and there is an overall screw belt shaft in the body of the drum. The motor reducer is located on the end face of the main equipment. 2, the mixture is relatively stable, and the damage to the crystal is small. 3, when the equipment is mixed, all the materials are in the overall motion state, and the power requirements are high. 4. The mixing time is relatively short. 5, China’s domestic use of the maximum 30 cubic meters. 6, mainly used with powder and powder or with viscous materials mixed, you can spray a lot of liquid into the material when mixing, the whole process of mixing the material can reflect the solid powder can also reflect the viscous, the application of thickened powder, gray surface, paint and so on.

In summary, the Ribbon Blender is an efficient and uniform mixing equipment, which is suitable for material mixing in many industries. The advantages of good mixing effect, simple operation and easy maintenance are widely used in chemical, food, medicine, daily chemical, agrochemical, feed, rubber and plastic industries, and play an important role in various industrial fields to help achieve uniform mixing of materials, improve product quality, but also improve production efficiency and process controllability. With the continuous development of the industry, the application field of the ribbon mixer will also continue to expand, ushering in a broader market prospect. If you need to mix and process in the production process, then the ribbon mixer is your first choice.

About LKMixer

LKMixer is a professional manufacturer for fertilizer production line, grinder, mixer and granulator, shredder. These machines are widely used in food, pharmaceutical, cosmetic, health care products and chemical industries. The Food materials like Peanut, mushroom, seeds, potato, bean, tobacco, salt, cannabis, tea, Sugar, corn, Coffee, rice, pepper, grain as so on. Grinders have many types such as Pulse Dust Grinder which suitable for zero pollution environment, Turbine Mill which is suitable for coffee bean, 12-120mesh all can meet, Ultrafine Grinding Mill covers 80-200mesh, and also Winnowing Dust Grinder or other grinding machines like SF Hammer. Welcome to contact us for details. Contact us for more information. Proposal, catalog, quotation. Mobile/WhatsApp: +86 18019763531 Tel: +86 21 66037855 Email: sales@lkmixer.com

Contact Us

Blender Videos

You may also interest in:

FAQ(Click and See More)

Why Choose Us?

We have 20 years manufacturing experiences; 15600 cubic meters factory area; 5000sets annual capacity; 55 professional engineers;

What’s your main maket?

South America: Brazil, Colombia, Peru, Bolivia, Uruguay, Paraguay ;Romania;

USA with UL Certification

Middle East: Saudi, Arabia, Oman, Turkey

Europe: Russia, Australia, Belarus, Ukraine, Poland

Can you support OEM?

– Yes, OEM or ODM. Machine can be customized according to customer detail requirement, including capacity and voltages, motor certifications.

– Drawing and raw materials also can be customized.

What after-sale services?

– 7*24 customer service online;

– 7*24 engineers online services;

– 12 months warranty services.

WHAT kind of MACHINE YOUR COMPANY HAVE?

CAN YOU GIVE ME GUIDE ON OTHER MACHINE ? TO FULL MY PRODUCTION LINE

YES ! Our f have factory build more than 20 years now, we can design and customize whole line, besides of the grinding machine, mixing machine, we can also fully support to provide the washing machine, cutting machine, drying machine, packing machine, filling machine. Though we are not producing these machine, but our brother companies co-work together for over 20 years, we have rich experience in providing you a full effective production line, fully automatically or semi-automatically.

HOW TO VISIT YOUR COMPANY?

Our Factory located in Jiangsu Province, very near to Shanghai, you can fly to Shanghai Pudong Airport, we pick you up and take you by car 2 hours ride, can reach our factory, welcome your visit.

WHAT’S YOUR BEFORE & AFTER SERVICE ?

1) Before your purchasing, we need to know your detail request, such as what kind of material you want to grind and mixing, what final product powder or granule you want to reach. Because different material and powder sizes request of different machine to do. We can provide professional advice and rich experience help to choose machine. Most of the products we have already did before for other customer, trail test or run mass production, so we knows which machine is best in performance of grinding and mixing. This is of very importance in helping you choose the right model. We also wish this can help our customer a lot. Even the material we didn’t do before, we will prepare the same material and to do the trail test and send video to you for your reference.

2) One Year guarantee of machine quality. If the machine have problem within one year, we will send you the spare parts to you for replacement, but this not including the damage caused by human causes. We also have 24 hours on line guide for customer, if you have operation difficulty, we will guide by video and on line communication with our engineer for your emergency debug.

3) For small machine, we sell with whole machine, it’s no need to install, and easy to operation, no problems for operation. While for large machine, its’s also not difficult to install with video guideline, but if you need, we can assign our technicians to go abroad, the round ticket, food and residents will be paid by customer.

HOW ABOUT YOUR PAYMENT TERM?

Our payment term is T/T. 50% payment in advance, rest of 50% payment finish before the goods shipped. When we finish the machine production we will do trail test and run the machine take videos for your green light. You pay the rest of 50% payment then.