Industrial Food Grinding Machine

With the continuous development of Industrial Food Grinding Machine technology, food grinder, as an important processing equipment, is more and more favored by the food industry. Food grinder can finely grind a variety of ingredients into granules or colloids, widely used in food, pharmaceutical, cosmetics and other fields.

The principle and classification of food grinder

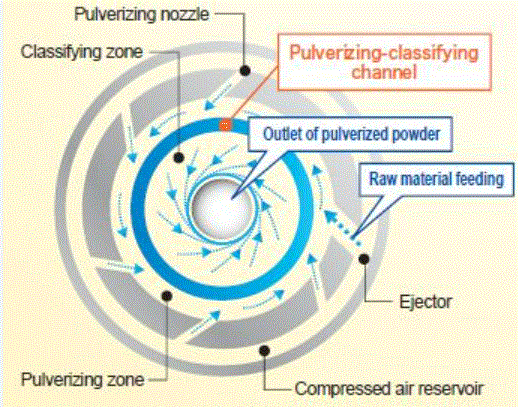

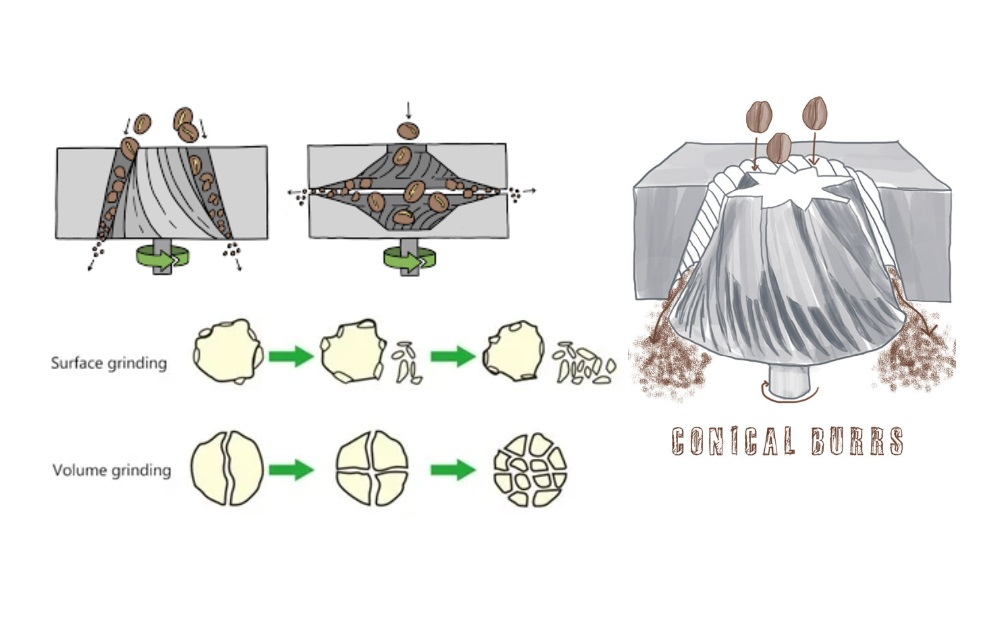

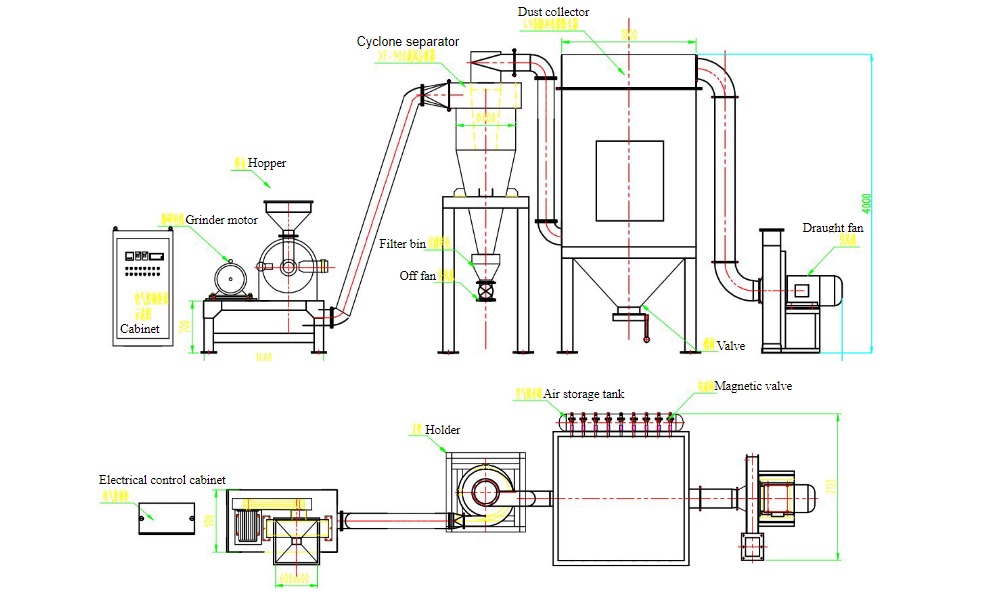

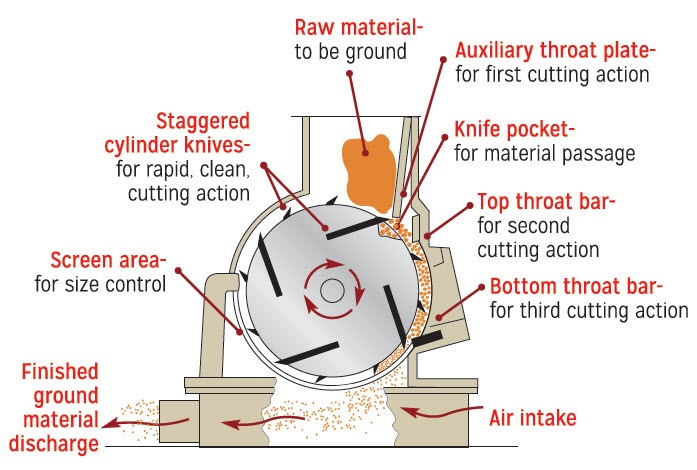

The Food Grinding Machine is a kind of equipment that uses the shear force between the high-speed rotating blade and the stator to grind the material into a glue. According to the different structure and working principle, it can be divided into plate type, cone form, tooth form and other types. Among them, the flat grinding machine has the characteristics of high grinding efficiency and easy maintenance, and is widely used in food processing.

Industrial Food Grinding Machine:

The advantages of food grinder

High grinding efficiency: The Food Grinding Machine can quickly grind the food into a granular or colloidal shape, greatly shortening the production cycle.

Processing health: In food processing, due to the shear force generated by the high-speed rotation of the blade and the stator, the microorganisms in the food can be completely eliminated during the processing, thus ensuring the health and safety of the product.

Easy maintenance: The maintenance of the Food Grinding Machine is relatively simple, and only requires regular cleaning and maintenance.

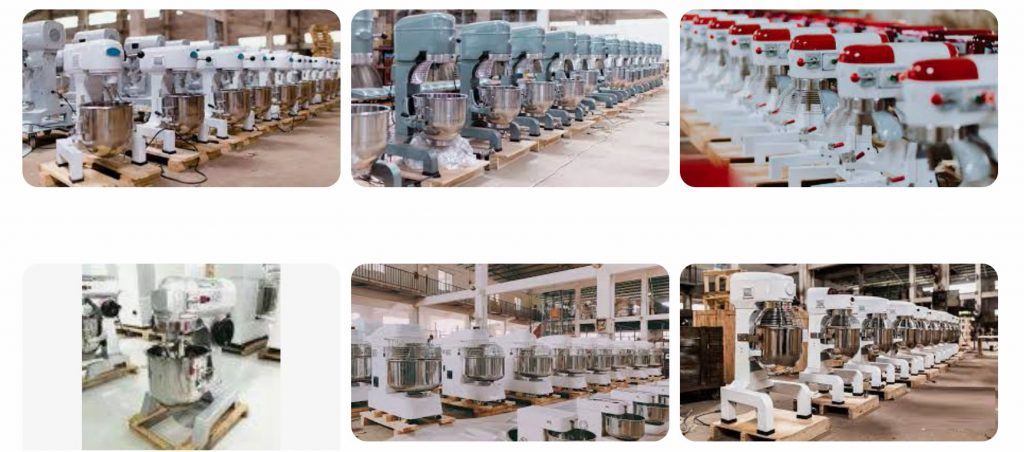

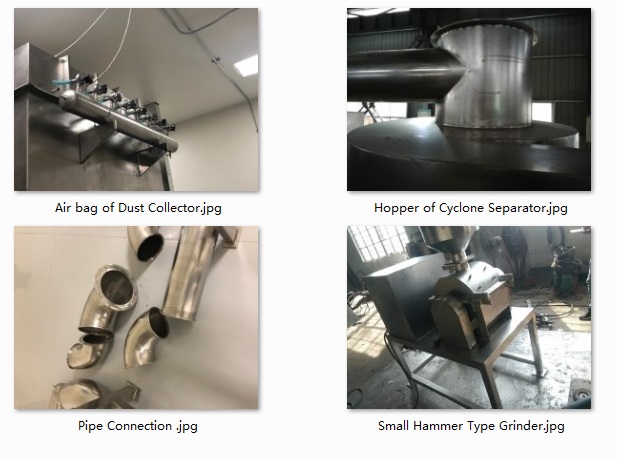

Domestic Shipment Show Case:

Customer Side Machine Groups Showcase Video:

FAQ (Click and See More)

Our products includs powder grinding mills, classifiers, coating machines, mixing machines, etc.

– We offer full services covers whole process of your new project. Including your factory feasibility assessment, process flow chart, preliminary factory machines layout and factory building planning, project budget estimation, project time schedule arrangements, etc.

– We supply sample processing tests as to your detail product. To estimate the capacity of machine, this helps you controls better to the capacity and get to know more accuracy of quantity of machine you need to book. In our test station where are equipped with our various machine products,this is also help you compare performances of different types of machines or process.

– For large machine. If neccessary, we can assign engineers to the your project site and offer on-site technical instruction and supervision during the machine installation, commissioning and test run.

Normally 60 to 90 days after receive the deposit payment.

– 50% by T/T deposit payment.

– 50% balance by T/T before shipment.

– For machines, we ship with export wooden box and pallet suitable for long time boat transportation in standard containers or Bulk by sea.

– For spare parts, wooden Case and pallet for delivery by air.

We send engineers to the clients’ project site and offer on-site technical instruction and supervision during the machine installation, commissioning and test run.

– Warranty period is 12 months after installation.

– We offer lifetime service for our machine products after the delivery, and will follow up the machine status with our clients after the successful machine installation in our clients’ factories.

For details, please contact our project consultants, thank you.

About LKMixer

LKMixer is a professional manufacturer for fertilizer production line, grinder, mixer and granulator, shredder. These machines are widely used in food, pharmaceutical, cosmetic, health care products and chemical industries. The Food materials like Peanut, mushroom, seeds, potato, bean, tobacco, salt, cannabis, tea, Sugar, corn, Coffee, rice, pepper, grain as so on. Grinders have many types such as Pulse Dust Grinder which suitable for zero pollution environment, Turbine Mill which is suitable for coffee bean, 12-120mesh all can meet, Ultrafine Grinding Mill covers 80-200mesh, and also Winnowing Dust Grinder or other grinding machines like SF Hammer. Welcome to contact us for details. Contact us for more information. Proposal, catalog, quotation. Mobile/WhatsApp: +86 18019763531 Tel: +86 21 66037855 Email: sales@lkmixer.com