High Speed Grinder GFSJ

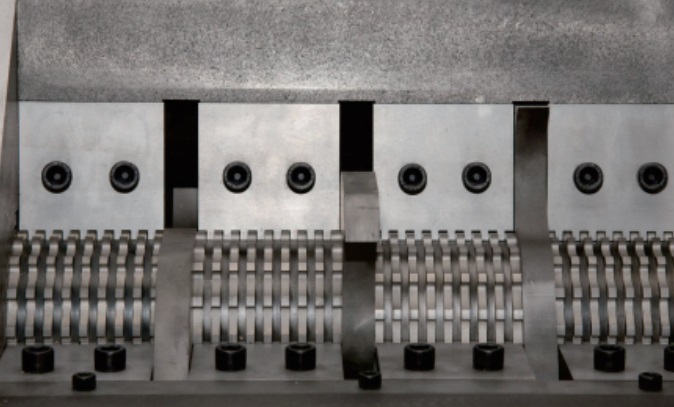

High Speed Grinder

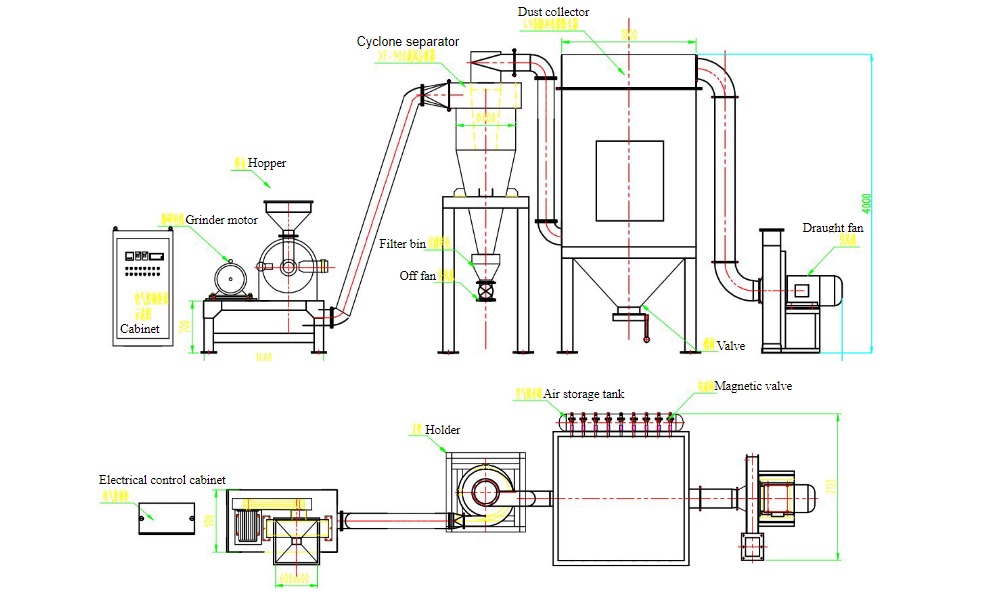

- Motor Power (KW): 1.1~4kw;

- Axis Rotating Speed(r/min):20;

- Dimension(mm):1000*450*1180~1240*610*1670.

- Unit Price of whole group including the grinder, cyclone seperator, dust collection: $ 12,000-41,538.

What is High Speed Grinder?

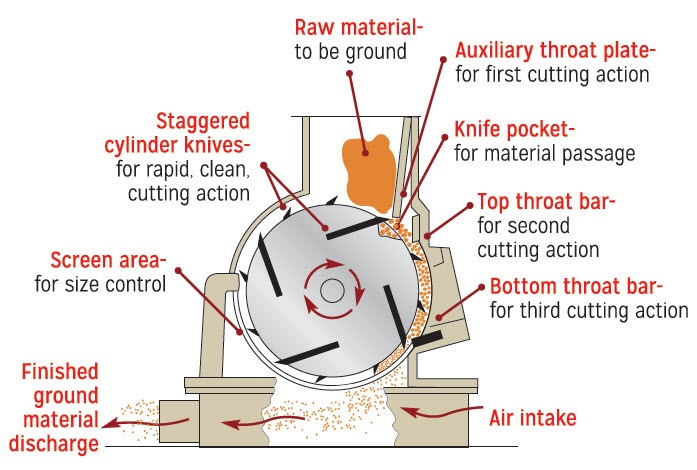

A high speed grinder is a type of power tool used for cutting, grinding, and polishing various materials at high speeds.. It typically features a small, handheld design and a high-powered motor that rotates a grinding wheel or cutting disc at very high speeds. The high speed of the wheel or disc allows for quick and efficient material removal or shaping. These grinders are typically used in industrial and commercial settings, such as manufacturing plants, construction sites, and metalworking shops, but they can also be used by DIY enthusiasts and hobbyists.

High speed grinders come in a variety of shapes and sizes, but they all share a few common features. They typically have a motor that drives a rotating grinding wheel or cutting disc, which is used to remove material from the workpiece. The speed of the grinding wheel or cutting disc can be adjusted to suit the material being worked on and the specific task being performed.

One of the main advantages of high speed grinders is their ability to remove material quickly and efficiently. This makes them ideal for tasks such as grinding, cutting, and shaping metal, stone, and other hard materials. They are also used for smoothing rough surfaces, preparing surfaces for welding or painting, and for removing rust or paint.

High speed grinders can be divided into two main categories: angle grinders and straight grinders. Angle grinders are the most common type of high speed grinder, and they are designed for cutting and grinding materials at a variety of angles. They have a compact, handheld design and are typically used for tasks such as cutting metal pipes, grinding down welds, and shaping metal or stone.

Straight grinders, on the other hand, are designed for precision grinding and cutting tasks. They have a longer, narrow shape and are typically used for tasks such as deburring, sanding, and polishing. Straight grinders are often used in metalworking and woodworking applications, and they can be fitted with a variety of attachments to suit different tasks.

Another important feature of high speed grinders is their safety features. Because they operate at high speeds and generate a significant amount of heat and debris, it is important to take appropriate safety precautions when using a high speed grinder. This may include wearing appropriate personal protective equipment, such as eye protection, gloves, and hearing protection, and ensuring that the workpiece is securely clamped or held in place during use.

In conclusion, high speed grinders are versatile and powerful tools that are essential in many industrial and commercial applications. Whether you are cutting, grinding, or shaping metal, stone, or other hard materials, a high speed grinder can help you get the job done quickly and efficiently. However, it is important to use these tools safely and to follow the manufacturer’s instructions to ensure optimal performance and prevent injury.

Applciation of High Speed Grinder:

High speed grinders are used in a variety of industrial and commercial applications where precision grinding, cutting, and shaping are required. These tools can be used to work with a wide range of materials, including metal, stone, wood, and plastic, making them versatile and essential tools in many industries.

One of the most common applications for high speed grinders is metalworking. High speed grinders are used to cut, shape, and grind metal components in manufacturing plants, repair shops, and construction sites. They are particularly useful for tasks such as deburring, grinding down welds, and preparing metal surfaces for welding or painting.

In the construction industry, high speed grinders are used to cut and shape concrete, stone, and other materials. They can be used to create precise cuts and angles in concrete slabs, as well as to grind down rough surfaces and remove old coatings and sealants. High speed grinders are also used to cut and shape stone for building facades, countertops, and other architectural features.

In the woodworking industry, high speed grinders are used to shape, sand, and polish wood components. They can be used to remove rough edges and splinters, as well as to shape and smooth wooden surfaces. High speed grinders are also used to create intricate designs and patterns in wood, as well as to sharpen and maintain woodworking tools.

High speed grinders are also used in the automotive industry, where they are used to cut and shape metal components for cars, trucks, ev chargers, and other vehicles. They are particularly useful for tasks such as grinding down welds, preparing metal surfaces for painting, and shaping metal parts for custom applications.

In the aerospace industry, high speed grinders are used to shape and cut metal components for airplanes, helicopters, and other aircraft. They can be used to create precision cuts and shapes, as well as to remove excess material and prepare metal surfaces for painting or other treatments.

High speed grinders are also used in the medical industry, where they are used to shape and polish dental and surgical instruments. They are particularly useful for tasks such as sharpening dental drills and creating precision cuts and shapes in surgical tools.

In the food industry, high speed grinders are used to grind, chop, and puree food ingredients for use in commercial kitchens and food production facilities. They are used to create sauces, purees, and other food products, as well as to grind meat and other ingredients for use in sausages, meatballs, and other products.

In conclusion, high speed grinders are essential tools in many industrial and commercial applications, where precision grinding, cutting, and shaping are required. High-speed grinders are commonly used in metalworking, woodworking, and construction industries, as well as in automotive and aerospace manufacturing. They can be used to grind, sand, polish, or cut materials such as metal, wood, plastics, ceramics, and composites. Some common applications include smoothing rough edges, removing excess material, and shaping or cutting various parts. They are versatile and can be used to work with a wide range of materials, making them an indispensable tool in many industries. From metalworking and construction to woodworking, automotive, aerospace, medical, and food industries, high speed grinders play a crucial role in many aspects of modern industry.

It is important to use high-speed grinders safely and with the proper protective equipment, as they can be dangerous if not used correctly. Users should always wear eye and ear protection, as well as gloves and a dust mask if necessary. It is also important to ensure that the tool is properly grounded and that the grinding wheel or cutting disc is securely attached before use.

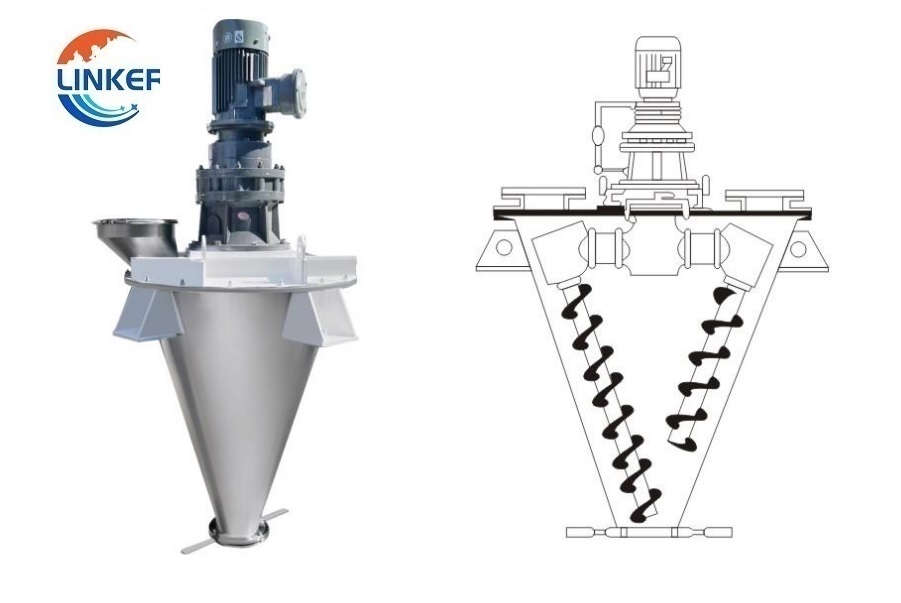

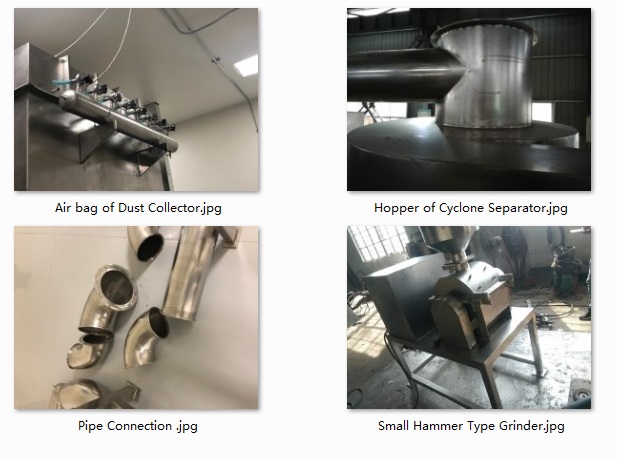

About LKMixer

LKMixer is a professional manufacturer for fertilizer production line, grinder, mixer and granulator, shredder. These machines are widely used in food, pharmaceutical, cosmetic, health care products and chemical industries. The Food materials like Peanut, mushroom, seeds, potato, bean, tobacco, salt, cannabis, tea, Sugar, corn, Coffee, rice, pepper, grain as so on. Grinders have many types such as Pulse Dust Grinder which suitable for zero pollution environment, Turbine Mill which is suitable for coffee bean, 12-120mesh all can meet, Ultrafine Grinding Mill covers 80-200mesh, and also Winnowing Dust Grinder or other grinding machines like SF Hammer. Welcome to contact us for details. Contact us for more information. Proposal, catalog, quotation. Mobile/WhatsApp: +86 18019763531 Tel: +86 21 66037855 Email: sales@lkmixer.com

Contact Us

High Speed Grinder:

Popular Low Speed Grinder for Sale:

Popular Medium Speed Grinder for Sale:

Other Food Grinder for Sale:

Coffee Grinder Youtube Video (More Videos)

Coffee Grinder Youtube Video (Hammer Type is NOT suitable for baked Coffee Bean, because it’s too oil.)

FAQ(Click and See More)

What is a high speed grinder?

A high speed grinder is a type of grinder that is designed to grind materials at a high rate of speed. These grinders are typically used in industrial applications where high productivity and efficiency are essential.

What types of materials can be ground with a high speed grinder?

High speed grinders are capable of grinding a wide range of materials, including metals, plastics, wood, and other organic materials. The exact types of materials that can be ground will depend on the specific grinder and its capabilities.

What are the advantages of using a high speed grinder?

The main advantage of using a high speed grinder is that it can grind materials much faster than traditional grinders, which can help increase productivity and efficiency. Additionally, high speed grinders can often grind materials to a finer degree of accuracy, which can be important in certain applications.

What safety precautions should be taken when using a high speed grinder?

When using a high speed grinder, it is important to wear appropriate safety gear, such as eye protection and gloves, to prevent injury from flying debris. It is also important to follow the manufacturer’s instructions for safe use and maintenance of the grinder.

How should a high speed grinder be maintained?

High speed grinders should be regularly cleaned and maintained to ensure optimal performance and safety. This may include replacing worn or damaged parts, lubricating moving parts, and cleaning the grinder after each use.

Can a high speed grinder be used for precision grinding?

Yes, some high speed grinders are designed for precision grinding and can be used to grind materials to a very high degree of accuracy. However, the specific capabilities of the grinder will depend on the model and manufacturer.

What is the cost of a high speed grinder?

The cost of a high speed grinder will vary depending on the size, capabilities, and manufacturer of the grinder. Industrial-grade high speed grinders can range in price from several thousand to tens of thousands of dollars.