Date Grinding Machine

- Capacity: 15-1500kg/h;

- Output granule Size: 60-320mesh;

- Application: Pharmaceuticals, Nutraceuticals, Food Products, Chemicals, Fertilizer, Stucco, Clay, Potting Soils.

- Notice: This is just an example. Please contact with our sales for choosing the right model.

- Price: $50~15,300.

- Certification: CE or UL Certification

Date Grinding Machine for Sale:

Date Grinding Machine is used to crush the dry Date into powder or granule, the powder size or granule size can be adjusted according to customer request, different granule or powder size use different machine type and model. LKMixer we have many different model for different materials. We can also customize the whole production line including the drying machine, conveyor, feeder, vibrating Screen. Please contact us for detail proposal and price.

Customization Date Grinding Machine According to your Capacity:

We can customize the capacity according to your special requirement, we can also customize the vacuum feeder connect with your production line (the dimension and width of feeder), for detail contact with our sales for proposal and price.

Videos of Date Grinding Machine:

We have many model of Date Grinding Machine, here show some example:

Product Information

What is Date Grinding Machine?

As we all know, the Pneumatic vacuum feeder utilizes compressed air to generate high vacuum through a vacuum generator, facilitating the delivery of materials without the need for a mechanical vacuum pump. It have many advantages, such as a simple structure, small volume, maintenance-free operation, low noise, convenient control, elimination of static electricity from materials, and compliance with GMP requirements. The high vacuum generated by the vacuum generator prevents the layering phenomenon of conveyed materials and ensures the homogeneity of mixed materials’ ingredients. It is the preferred equipment for automatic loading in machinery such as tablet presses, blenders, capsule filling machines, dry granulators, packaging machines, pulverizers, vibrating screens, etc.

Technical parameters of Date Grinding Machine:

| Model | Capacity | Input granule Particle(mm) | Output particle (mesh) | Power(KW) |

| LKJB-350 | – | – | – | – |

| LKJB-450 | 100-500 | <100*20 | 10-60 | 30.25 |

| LKJB-550 | 150-700 | <100*20 | 10-60 | 41.75 |

| LKJB-650 | 200-1100 | <100*20 | 10-60 | 60.75 |

| LKJB-850 | 300-1500 | <100*20 | 10-60 | 74.25 |

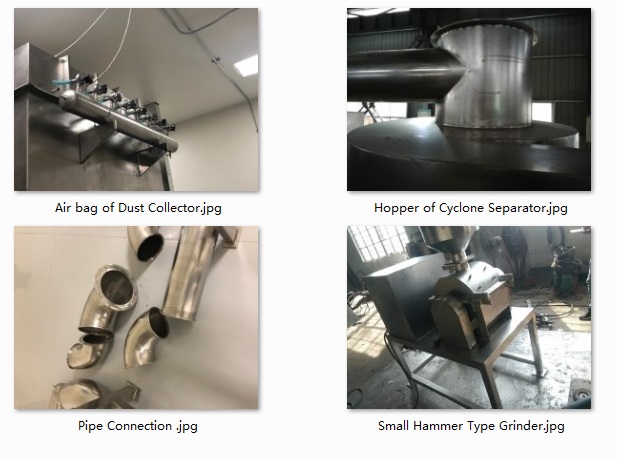

Pictures of Ginger Garlic Grinding Machine:

Feature and Benefits of Date Grinding Machine:

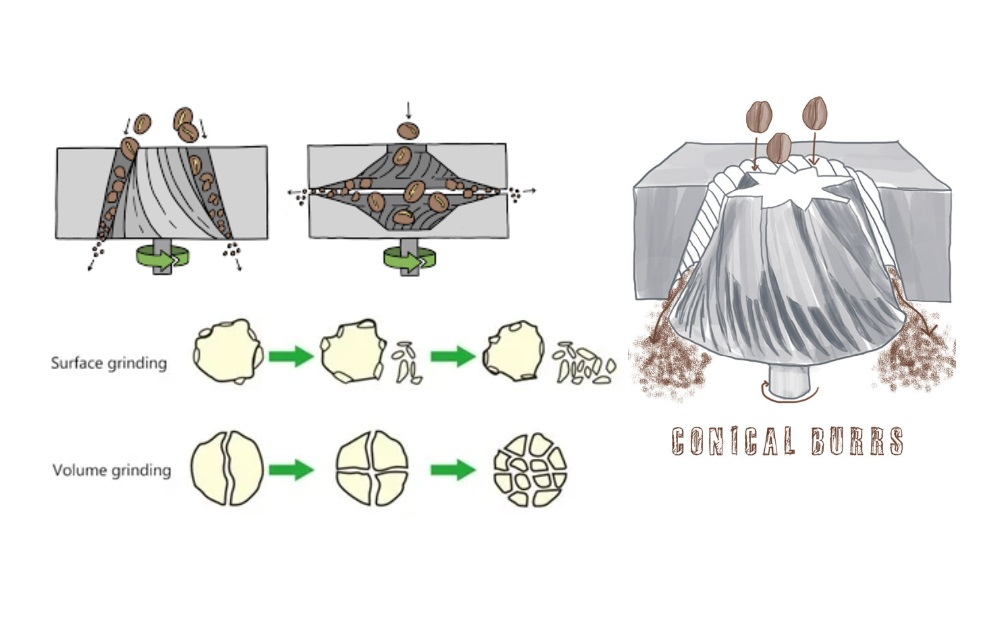

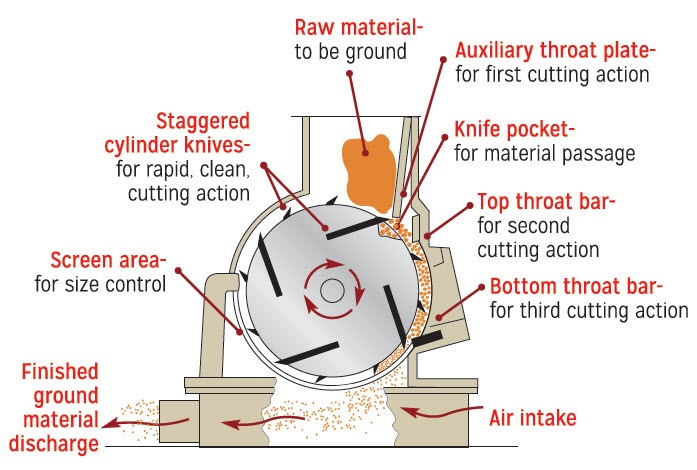

With the Compact design, and compared to the micro-grinding unit, this machine has more pre-processing hammer for coarse crushing, so that large particles of material can be directly crushed, continuous crushing process, no dust. Fine powder trapped by dust traps can be effectively recovered, reducing the material loss rate.

Application of Date Grinding Machine:

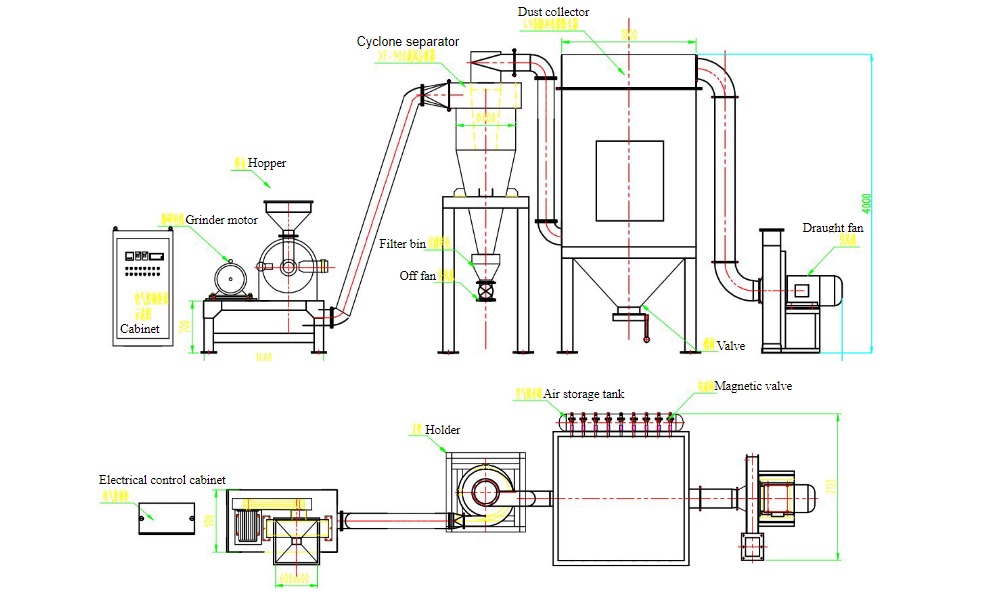

The Garlic Grinding Machine is composed of a hammer host, an ultra-micro host, a cyclone separator, and an impulse dust box. It has a variety of properties such as no screen, no mesh, uniform discharge particle size, etc. The production process is continuous and can directly load large particles crushed into fine powder. This machine is applied in such trades as pharmaceutical, chemical, and foodstuff. It can crush chili, pepper, black pepper, white pepper, green pepper, cinnamon, cumin, bandits, pepper, cinnamon, nutmeg, cardamom, red yeast rice, red pepper, garlic, star anise, cloves, Amomum Tsaoko, geraniol, turmeric ginger, fennel, anise, angelica, and other materials with a high content of oil or fiber. Besides, the material can be fed into the machine directly without coarse crushing. It has the features of big capacity, not changing the color, and maintaining the physico-chemical characteristics of the material.

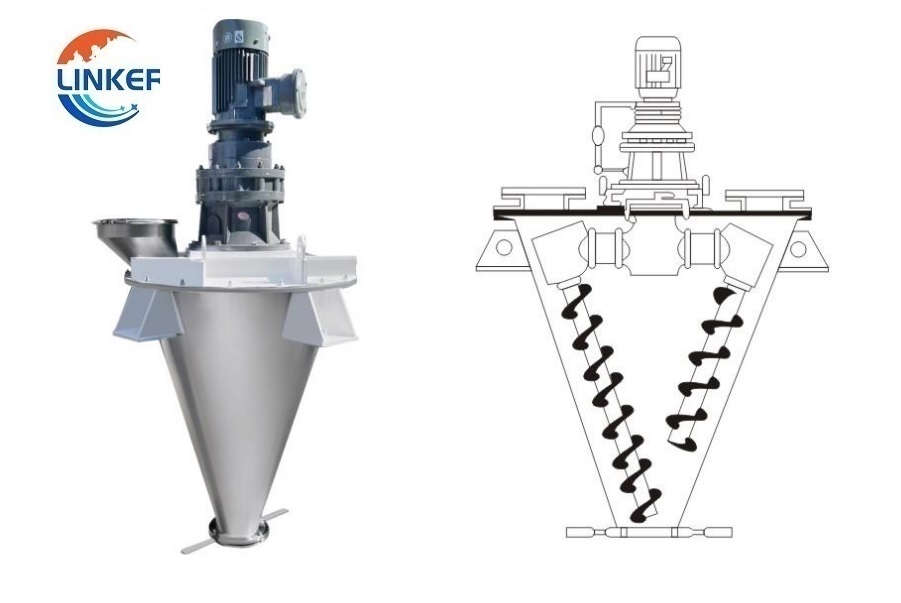

Working Principle of Date Grinding Machine:

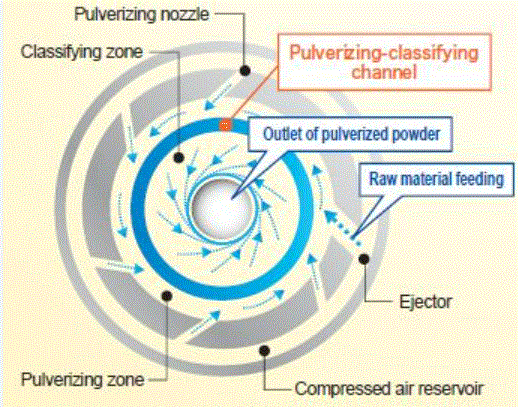

It makes use of the high-speed relative movement of the movable fluted disc and the fixed disc to crush the materials through the comprehensive effect of striking and friction of the fluted disc. The crushed material flows into the cyclone separator by the gravitation of blower and rotating centrifugal force, then discharges through gate blower. At the same time, the dust come into the pulse dust-evaluator box, filtrated and recycled by the filter cylinder.

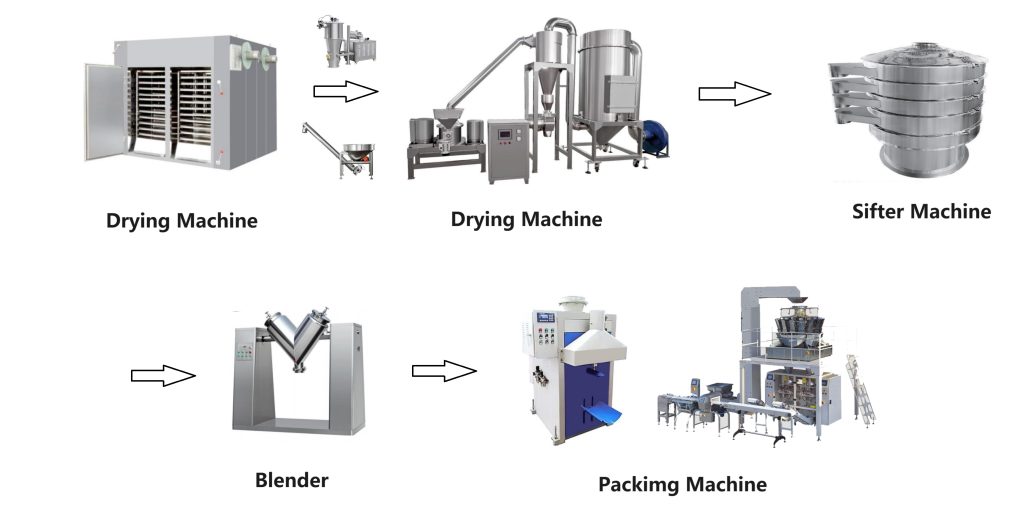

Production Line Customization Solution:

LINKER is a manufacturer of grinding and mixing machine. We can customize whole automatic production line according to customer special request. According to your special material, capacity requirement and motor and electric cabinet certification requirement, we can customize semi-auto or fully automatic production line for our customer. Please contact us for detail proposal and quotation.

Drying Machine + Grinding Machine + Sifter Machine + Mixing Machine + Packing Machine:

Production Line Customization Videos(See More Videos):

Fertilizer Production Line

Blending Production Line

Wheat Flour Production Line

Factory Information

Factory Information

| Business Type: | Manufacturer/Factory | Main Products: | Mill, grinder, granulator, mixer, Crushing Equipment |

| Number of Employees: | 100 | Year of Establishment: | 2014.05 |

| Production Capacity | 5000 Set/Year | After-sales Service: | Technical Support; on-line teach lessons |

| R&D Capacity: | ODM, OEM | Annual Output Value: | US$5 Million – US$10 Million |

| No. of R&D Staff: | 5 | No. of Production Lines: | 6 |

LK Mixer is a professional manufacturer for grinder, mixer and pulverizer, granulator. These machines are widely used in pharmaceutical, cosmetic, health care products and chemical industries. Our main product including granulating machine, grinder, mixer, dryer, etc. All mechanical products in accordance with the China GMP design requirements. And also we have other certifications such as CE, UL for motors.

Business Philosophy: “Quality is the main policy of sales” and “integrity is the principle of success” are the business philosophy of our people. We carry out one-year warranty, lifelong maintenance service, with technical consultation, with material test machine and other services, and long-term supply of equipment. Welcome new and old customers to negotiate cooperation!

Certifications:

Small Machine Packing:

Small machine packed with export fumigation-free wooden cases, goes with bulk shipment or in container.

Large Machine Packing:

Shipment Show Case: Small grinder machine ship for Masala, Pakistan, Kenya, Nepal, India…

Normal Problems that May Meet:

Motor instruction

This series of motors can continuously output rated exciting force when the following conditions are met.

- vibration acceleration: not more than 7g (g: acceleration of gravity)

- ambient temperature: not more than 40℃

- altitude: not more than 1000m

- Power frequency: 50Hz

- Voltage: 380V or customization

- temperature rise: less than 80K (resistance method)

- Preparation before installation: 1, check whether the motor sign is in line with the requirements; 2, with 500 volts megohm meter to measure the insulation resistance, its value should be dried stator winding, drying temperature can not exceed 120℃; 3, check the fasteners of the motor, beware of loosening; 4, check the motor surface for damage and deformation; 5, check whether the rotation is flexible, if there is an anomaly, should be excluded; 6, check the power supply, whether there is a lack of phase, and no-load operation for 5 minutes.

Installation and adjustment

- The motor should be fastened on the mounting surface, and the mounting surface must be smooth and flat; 2, the motor can be installed horizontally; 3, the motor lead adopts four-core rubber cable YZ-500V, the lead cable is not allowed to have a sharp break when connecting the power supply, and is reliably fixed with the vibrating body; 4, the motor should have reliable grounding, the motor has a grounding device, the lead end is marked, and the solid bolt can also be used to ground.

- Adjustment of exciting force.

- Try to start two vibration motors, which require the two vibration motors to run at equal speed in reverse. If it runs in the same direction, replace any two-phase power supply wiring of one of the vibration motors.

- the trial operation time of the vibrating screen shall not be less than 8 hours, and the trial operation can be tested by naked eye observation and instrument detection. The vibrating screen should start smoothly, quickly, work vibration is stable and reliable, no special noise, the various technical performance parameters of the vibrating screen meet the requirements of the drawing, and the vibrating screen box shall not produce lateral swing.

Use and maintenance - The machine shall be equipped with electrical protection device.

- In the early stage of operation, check the anchor bolt at least once a day to prevent loosening.

- when the motor rotation direction does not meet the requirements, adjust the phase sequence of the power supply.

- the motor should ensure good lubrication, every two weeks or so to add lithium grease (ZL-3) once, refueling, through the oil cup to add an appropriate amount of lithium grease. When sealed bearings are used, the motor is not equipped with oil cups.

- the machine has been running for 1500 hours, should check the bearing, if there is serious damage should be replaced immediately.

- When the machine is used again after being stopped for a long time, the insulation resistance should be measured for 500 volt megohm meter measurement, which should be greater than 0.5 megohm.

Daily maintenance - Before starting:

(1) Check the coarse mesh and fine mesh for damage

(2) Whether each group of bunches is locked - When starting:

(1) Pay attention to any abnormal noise

(2) Whether the current is stable

(3) There is no difference in vibration - after use: clean up after each use.

- Regular maintenance: Check the coarse mesh, fine mesh and spring regularly for fatigue and damage, whether the parts of the fuselage are damaged due to vibration, and the parts that need to add lubricating oil must be lubricated.

Warranty of Machine:

We provide one year warranty for all our machine, but not including the man-made damage. We can provide free spare parts if damage in one year in normal operation. 24hours stand by to solve urgent problems. 3 days of spare parts provide by express. Please specially notice for the motor connection. it should be connect in right way to prevent the motor burnt, take special notice of running machine safely. Machine need to be clean and maintained frequently.

Maintenance of machine:

Before installation, verify the site foundation with the screen installation drawing, ensuring the flatness error of the embedded steel plate is less than 3mm. Following the sequence of sieve installation from bottom to top, adjust each link to a preliminary qualified state before proceeding with the next link installation.

Next, install the screen and adjust its relative position. Ensure that the primary and secondary vibration damping springs are vertical, with the motor axis positioned 3-5mm lower than the axis of the exciter. Subsequently, spot weld the motor bracket, spring base, and embedded steel plate. It is imperative that the two motors rotate in opposite directions, and the exciter eccentric blocks are in the same phase.

Allow the vibrating screen to run for 4-6 hours without a load, ensuring the screen body operates smoothly, without rocking or emitting abnormal sounds. Additionally, inspect the fastening status of the screen plate and exciter.

About LKMixer

LKMixer is a professional manufacturer for fertilizer production line, grinder, mixer and granulator, shredder. These machines are widely used in food, pharmaceutical, cosmetic, health care products and chemical industries. The Food materials like Peanut, mushroom, seeds, potato, bean, tobacco, salt, cannabis, tea, Sugar, corn, Coffee, rice, pepper, grain as so on. Grinders have many types such as Pulse Dust Grinder which suitable for zero pollution environment, Turbine Mill which is suitable for coffee bean, 12-120mesh all can meet, Ultrafine Grinding Mill covers 80-200mesh, and also Winnowing Dust Grinder or other grinding machines like SF Hammer. Welcome to contact us for details. Contact us for more information. Proposal, catalog, quotation. Mobile/WhatsApp: +86 18019763531 Tel: +86 21 66037855 Email: sales@lkmixer.com

Contact Us

FAQ(Click and See More)

Why Choose Us?

We have 20 years manufacturing experiences; 15600 cubic meters factory area; 5000sets annual capacity; 55 professional engineers;

What’s your main market?

South America: Brazil, Colombia, Peru, Bolivia, Uruguay, Paraguay ;Romania;

USA with UL Certification

Middle East: Saudi, Arabia, Oman, Turkey

Europe: Russia, Australia, Belarus, Ukraine, Poland

Can you support OEM?

– Yes, OEM or ODM. Machine can be customized according to customer detail requirement, including capacity and voltages, motor certifications.

– Drawing and raw materials also can be customized.

What after-sale services?

– 7*24 customer service online;

– 7*24 engineers online services;

– 12 months warranty services.

WHAT kind of MACHINE YOUR COMPANY HAVE?

CAN YOU GIVE ME GUIDE ON OTHER MACHINE ? TO FULL MY PRODUCTION LINE

YES ! Our f have factory build more than 20 years now, we can design and customize whole line, besides of the grinding machine, mixing machine, we can also fully support to provide the washing machine, cutting machine, drying machine, packing machine, filling machine. Though we are not producing these machine, but our brother companies co-work together for over 20 years, we have rich experience in providing you a full effective production line, fully automatically or semi-automatically.

HOW TO VISIT YOUR COMPANY?

Our Factory located in Jiangsu Province, very near to Shanghai, you can fly to Shanghai Pudong Airport, we pick you up and take you by car 2 hours ride, can reach our factory, welcome your visit.

WHAT’S YOUR BEFORE & AFTER SERVICE ?

1) Before your purchasing, we need to know your detail request, such as what kind of material you want to grind and mixing, what final product powder or granule you want to reach. Because different material and powder sizes request of different machine to do. We can provide professional advice and rich experience help to choose machine. Most of the products we have already did before for other customer, trail test or run mass production, so we knows which machine is best in performance of grinding and mixing. This is of very importance in helping you choose the right model. We also wish this can help our customer a lot. Even the material we didn’t do before, we will prepare the same material and to do the trail test and send video to you for your reference.

2) One Year guarantee of machine quality. If the machine have problem within one year, we will send you the spare parts to you for replacement, but this not including the damage caused by human causes. We also have 24 hours on line guide for customer, if you have operation difficulty, we will guide by video and on line communication with our engineer for your emergency debug.

3) For small machine, we sell with whole machine, it’s no need to install, and easy to operation, no problems for operation. While for large machine, its’s also not difficult to install with video guideline, but if you need, we can assign our technicians to go abroad, the round ticket, food and residents will be paid by customer.

HOW ABOUT YOUR PAYMENT TERM?

Our payment term is T/T. 50% payment in advance, rest of 50% payment finish before the goods shipped. When we finish the machine production we will do trail test and run the machine take videos for your green light. You pay the rest of 50% payment then.

Rotary sifter VS fixed sifter:

The first process of combined alkali production involves washing and refining solid salt, with the grinding washing process serving as an example.

During transportation, raw materials become mixed with debris, especially stones, which enter the system along with the raw materials. If not promptly addressed, this situation is likely to increase the content of finished insoluble matter. Stones are prone to blocking the pump, disrupting the fluid transport of solid materials, and may even lead to complete pipeline blockages, thereby posing a threat to production. Workers often have to clean the pump, increasing their labor intensity.

To address this issue, it is necessary to employ screening methods to remove debris such as stones. In the past, a fixed screen was utilized, positioned at the outlet of the raw material slurry flow. However, operating this fixed screen was inconvenient, with poor working conditions. Workers had to manually remove stones every half hour, risking cuts from sharp iron and enduring the harsh conditions, particularly in cold winters. Furthermore, the fixed screen’s performance was inconsistent; excessive stone buildup could block the pump, leading to wasted labor and filler, detrimental to pump service life. Additionally, changing the pump would result in water expansion and loss.

Nowadays, rotary sieves are employed, with a cylindrical sieve welded at the outlet of the ball mill and rotating with the body. Rotary sieves offer easy operation, automatically removing stones and improving working conditions. They provide stable stone removal, completely eliminating the need for pump cleaning, thereby reducing the content of finished insoluble matter.