GFSJ Industrial Dry Grinder

GFSJ High Effective Dry Grinder

- Powder Size: 12-120mesh

- Capacity: 50-3000kg/h

- Motor Power (KW): 7.5-18.5kw;

- Axis Rotating Speed(r/min):1000-4400;

- Dimension(mm):900*800*158000~5500*1200*3250.

- FOB Unit Price: 1 unit $ 12,000~41,538. More than 5 units: $10,800~37,385 Video

- Application: metal, Medicine, potato, bean, rice, herb, pepper, grain, food, corn, Sugar

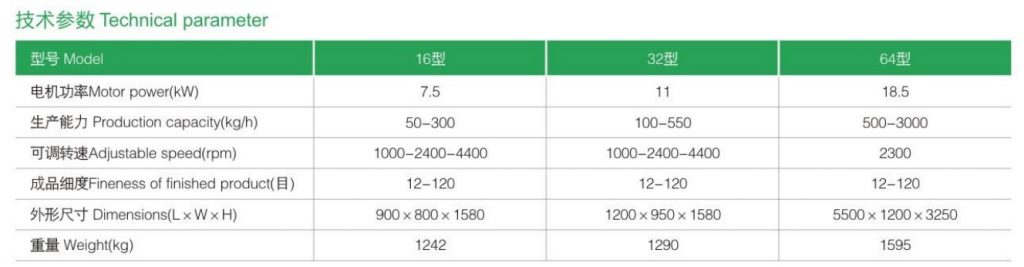

Parameter of Industrial Dust Grinder:

| Model | GFSJ16GFSJGFSJ-G |

| Motor Power(KW) | 7.5 |

| Production Capacity(KG/H) | 50-300 |

| Adjustable Speed(RPM) | 1000-2400-4400 |

| Fineness of Finished Product(Mesh) | 12-120 |

| Dimension(L*W*H)(mm) | 900*800*1580 |

| Weight(KG) | 1242 |

| Model | GFSJ32 |

| Motor Power(KW) | 11 |

| Production Capacity(KG/H) | 100-550 |

| Adjustable Speed(RPM) | 1000-2400-4400 |

| Fineness of Finished Product(Mesh) | 12-120 |

| Dimension(L*W*H)(mm) | 1200*950*1580 |

| Weight(KG) | 1290 |

| Model | GFSJ64 |

| Motor Power(KW) | 18.5 |

| Production Capacity(KG/H) | 500-3000 |

| Adjustable Speed(RPM) | 2300 |

| Fineness of Finished Product(Mesh) | 12-120 |

| Dimension(L*W*H)(mm) | 5500*1200*3250 |

| Weight(KG) | 1595 |

I. Introduction

Brief explanation of what a dry grinder is

A dry grinder is a kitchen appliance used to grind dry food ingredients such as spices, herbs, coffee beans, grains, and nuts into fine powders or coarse particles. Dry grinders typically consist of a motor, a grinding chamber, and a lid with a grinder blade. The motor powers the blade, which rotates inside the grinding chamber to break down the food ingredients into smaller pieces. Dry grinders can be manual or electric, and they come in various sizes and designs, depending on the intended use and capacity. They are commonly used in households, restaurants, and food processing industries to prepare ingredients for cooking, baking, or other culinary purposes.

Importance of dry grinders in various industries

Dry grinders are important tools in many industries due to their ability to efficiently process and prepare dry ingredients. Some of the industries that rely on dry grinders include:

- Food and Beverage Industry: Dry grinders are widely used in the food and beverage industry to grind various dry ingredients such as spices, herbs, grains, and coffee beans. They are used in restaurants, cafes, and bakeries to prepare fresh spices, flours, and coffee grounds for cooking and baking.

- Pharmaceutical Industry: In the pharmaceutical industry, dry grinders are used to grind dry herbs, roots, and other natural ingredients to create powders for use in medicines and supplements.

- Cosmetics Industry: The cosmetics industry uses dry grinders to grind dry ingredients such as minerals, pigments, and botanicals for use in makeup, skincare, and personal care products.

- Chemical Industry: Dry grinders are also used in the chemical industry to grind dry chemicals such as fertilizers, dyes, and pigments for use in various applications.

Overall, dry grinders are essential tools for efficiently and accurately processing dry ingredients in many industries, allowing for consistent quality and faster production times.

II. Literature Review

Historical overview of dry grinders

The history of dry grinders dates back to ancient times when early civilizations used simple grinding tools to process dry ingredients. The first known mechanical grinder was invented by the ancient Greeks in the 3rd century BCE. This grinder, known as a rotary quern, consisted of two circular stones that were manually rotated to grind grains into flour.

During the Middle Ages, water-powered mills were developed, which used the force of water to turn grinding stones and process grains into flour. With the Industrial Revolution in the 18th and 19th centuries, electrically powered mills and grinders were developed, which greatly increased efficiency and production capacity.

In the early 20th century, the first electric coffee grinders were invented, which allowed for easier and faster grinding of coffee beans. As technology continued to improve, the design and functionality of dry grinders evolved, with advancements such as adjustable grinding settings and automatic shutoff features being introduced.

Today, dry grinders come in a wide range of designs and styles, from small manual grinders to large electric models used in commercial kitchens and food processing facilities. While the basic principles of grinding dry ingredients have remained the same, modern dry grinders incorporate advanced technologies to make the process faster, more efficient, and more convenient.

Types of dry grinders and their applications

There are several types of dry grinders available, each with their own unique features and applications. Here are some of the most common types:

- Blade Grinders – Blade grinders are the most basic type of dry grinder, and consist of a simple blade attached to a motor. They are ideal for grinding coffee beans and spices, and are often compact and affordable.

- Burr Grinders – Burr grinders use two revolving abrasive surfaces, or burrs, to crush the dry ingredients. They produce a more consistent grind than blade grinders and are ideal for grinding coffee beans, spices, and grains.

- Mortar and Pestle – The mortar and pestle is a simple, manual tool used for grinding dry ingredients such as herbs and spices. The ingredients are placed in the mortar and crushed with the pestle, which is a heavy tool made of stone, wood, or metal.

- Food Processors – Food processors can also be used as dry grinders, as they typically come with a grinding attachment. They are versatile tools that can grind a wide variety of dry ingredients, including nuts, grains, and spices.

- Electric Grain Mills – Electric grain mills are powerful machines that are designed specifically for grinding grains into flour. They are ideal for home bakers who want to grind their own flour, as well as for commercial bakeries and food processing facilities.

- Commercial Dry Grinders – Commercial dry grinders are heavy-duty machines used in commercial kitchens and food processing facilities. They are designed to grind large quantities of dry ingredients quickly and efficiently, and can be used for a wide variety of applications, including grinding spices, coffee beans, and grains.

Overall, the type of dry grinder chosen will depend on the specific application and the amount of grinding required. Blade grinders and burr grinders are suitable for home use, while mortar and pestles are ideal for smaller quantities. For larger quantities and commercial use, electric grain mills and commercial dry grinders are the best options.

Advantages and disadvantages of dry grinders

Like any kitchen appliance, dry grinders have their own set of advantages and disadvantages. Here are some of the most common advantages and disadvantages of using a dry grinder:

Advantages:

- Speed and Efficiency: Dry grinders are designed to grind dry ingredients quickly and efficiently, which saves time and effort in the kitchen.

- Consistency: Dry grinders can produce a consistent grind, which is important for certain recipes that require uniform texture.

- Customization: Many dry grinders offer adjustable settings, allowing the user to customize the grind size to their specific needs.

- Versatility: Dry grinders can be used to grind a wide variety of dry ingredients, including coffee beans, spices, grains, and nuts.

- Cost-Effective: Many dry grinders are affordable, making them an accessible option for home cooks and small businesses.

Disadvantages:

- Noise: Some dry grinders can be loud, which can be a nuisance in the kitchen.

- Heat Generation: Some dry grinders can generate heat, which can affect the quality of the ground ingredients, especially if the grinder is used for a long time.

- Capacity: Some dry grinders have limited capacity, which can be a drawback if a large quantity of ingredients needs to be ground.

- Maintenance: Dry grinders require regular cleaning and maintenance to ensure their longevity and prevent the accumulation of debris.

Overall, the advantages of using a dry grinder often outweigh the disadvantages, especially when considering the speed, efficiency, and versatility of the appliance.

| Business Type: | Manufacturer/Factory | Main Products: | Mill, grinder, granulator, mixer, Crushing Equipment |

| Number of Employees: | 100 | Year of Establishment: | 2014.05 |

| Production Capacity | 5000Set/Year | After-sales Service: | Technical Support; on-line teach lessons |

| R&D Capacity: | ODM, OEM | Annual Output Value: | US$5 Million – US$10 Million |

| No. of R&D Staff: | 5 | No. of Production Lines: | 6 |

LK Mixer is a professional manufacturer for grinder, mixer and pulverizer. These machines are widely used in pharmaceutical, cosmetic, health care products and chemical industries. Our main product including granulating machine, grinder, mixer, dryer, etc. All mechanical products in accordance with the China GMP design requirements. And also we have other certifications such as CE, UL for motors.

Business Philosophy

“Quality is the main policy of sales” and “integrity is the principle of success” are the business philosophy of our people. We carry out one-year warranty, lifelong maintenance service, with technical consultation, with material test machine and other services, and long-term supply of equipment. Welcome new and old customers to negotiate cooperation!

Certifications:

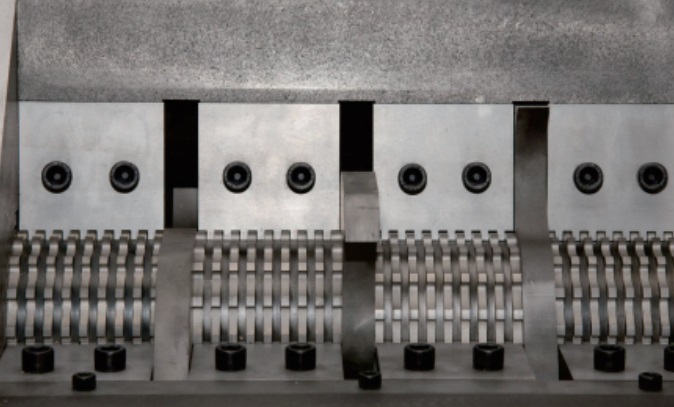

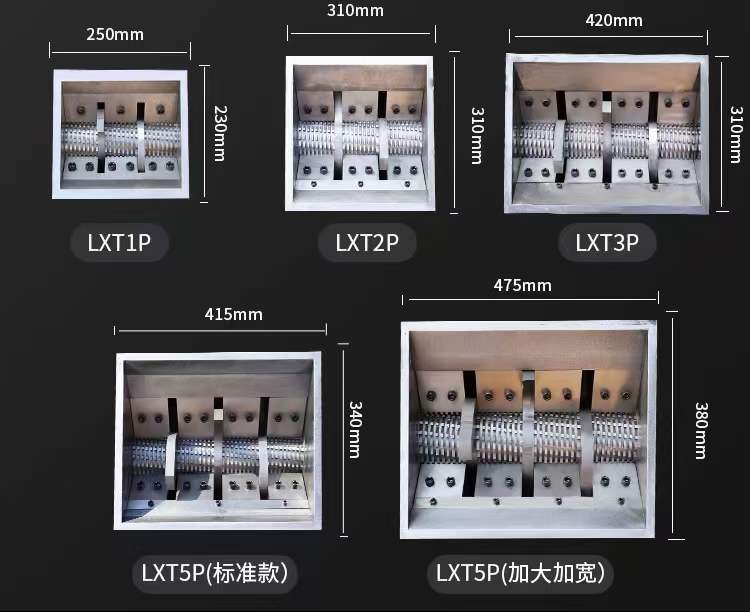

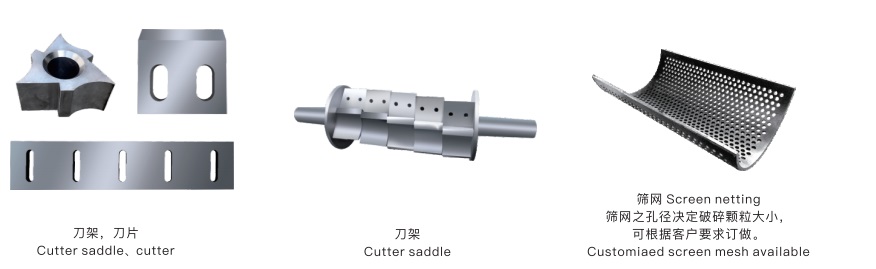

Cutting Knife Type Pictures:

Electric Cabinet with UL Certification

Cyclone Processor and Motors:

Spare Parts:

Small Machine Packing:

Small machine packed with export fumigation-free wooden cases, goes with bulk shipment or in container.

When packing small machines for sea shipment, it is important to take measures to ensure that the machines are protected from damage during transit. Here are some general steps that a manufacturer may follow when packing small machines for sea shipment:

- Clean and dry the machine: Before packing, the machine should be thoroughly cleaned and dried to prevent any moisture or debris from causing damage during transit.

- Disassemble the machine: If possible, the machine should be disassembled into its component parts to reduce its overall size and make it easier to pack.

- Wrap the machine in protective material: The machine should be wrapped in a layer of protective material, such as bubble wrap or foam, to protect it from scratches and impact during transit.

- Place the machine in a sturdy box: The wrapped machine should then be placed in a sturdy box that is appropriate for the size and weight of the machine. The box should be made of durable material, such as corrugated cardboard or plywood, and should be able to withstand the rigors of sea transit.

- Add packing material: The box should be filled with packing material, such as packing peanuts or air pillows, to provide cushioning and prevent the machine from shifting during transit.

- Seal the box: The box should be securely sealed with high-quality packing tape to prevent it from opening during transit.

- Label the box: The box should be clearly labeled with the machine’s name, weight, and any other relevant information, as well as the destination address and contact information.

Overall, the goal is to pack the small machine in a way that will protect it from damage during transit and ensure that it arrives at its destination in good condition. It is important to follow proper packing procedures and use high-quality packing materials to minimize the risk of damage during sea shipment.

Large Machine Packing:

Packing a large machine for sea shipment can be a complex and challenging task. However, with careful planning and attention to detail, it is possible to pack a large machine for sea shipment in a way that will ensure that it arrives at its destination in good condition. Here are some general steps that a manufacturer may follow when packing up a large machine for sea shipment:

- Clean and prepare the machine: Before packing, the machine should be thoroughly cleaned and prepared. All fluids, such as oil or coolant, should be drained, and any loose or detachable parts should be removed.

- Disassemble the machine: If possible, the machine should be disassembled into its component parts to reduce its overall size and make it easier to pack. Each part should be carefully labeled and numbered to ensure that it can be easily reassembled at the destination.

- Protect delicate parts: Delicate or fragile parts should be wrapped in protective material, such as bubble wrap or foam, to protect them from damage during transit.

- Build a custom crate: A custom crate should be built around the machine to provide a secure and sturdy enclosure. The crate should be made of durable material, such as plywood, and should be designed to fit the machine snugly. The crate should also include braces or supports to prevent the machine from shifting during transit.

- Add cushioning material: The crate should be filled with cushioning material, such as packing peanuts or air pillows, to provide extra protection and prevent the machine from moving or shifting during transit.

- Securely fasten the machine: The machine should be securely fastened to the crate to prevent it from moving or shifting during transit. This may involve using straps, bolts, or other fasteners to hold the machine in place.

- Seal and label the crate: The crate should be securely sealed with high-quality packing tape, and should be clearly labeled with the machine’s name, weight, and any other relevant information. The destination address and contact information should also be clearly marked on the crate.

Overall, packing a large machine for sea shipment requires careful planning and attention to detail. It is important to use high-quality materials and follow proper packing procedures to ensure that the machine arrives at its destination in good condition. A professional packing and shipping company may be consulted to ensure that the machine is properly packed and prepared for sea shipment.

Customer Side Machine Groups Showcase Videos:

Dust Collector Shipment

Shipment – Packing Method

Two Large Industrial Grinder Ready to Ship

Domestic Shipment Show Case:

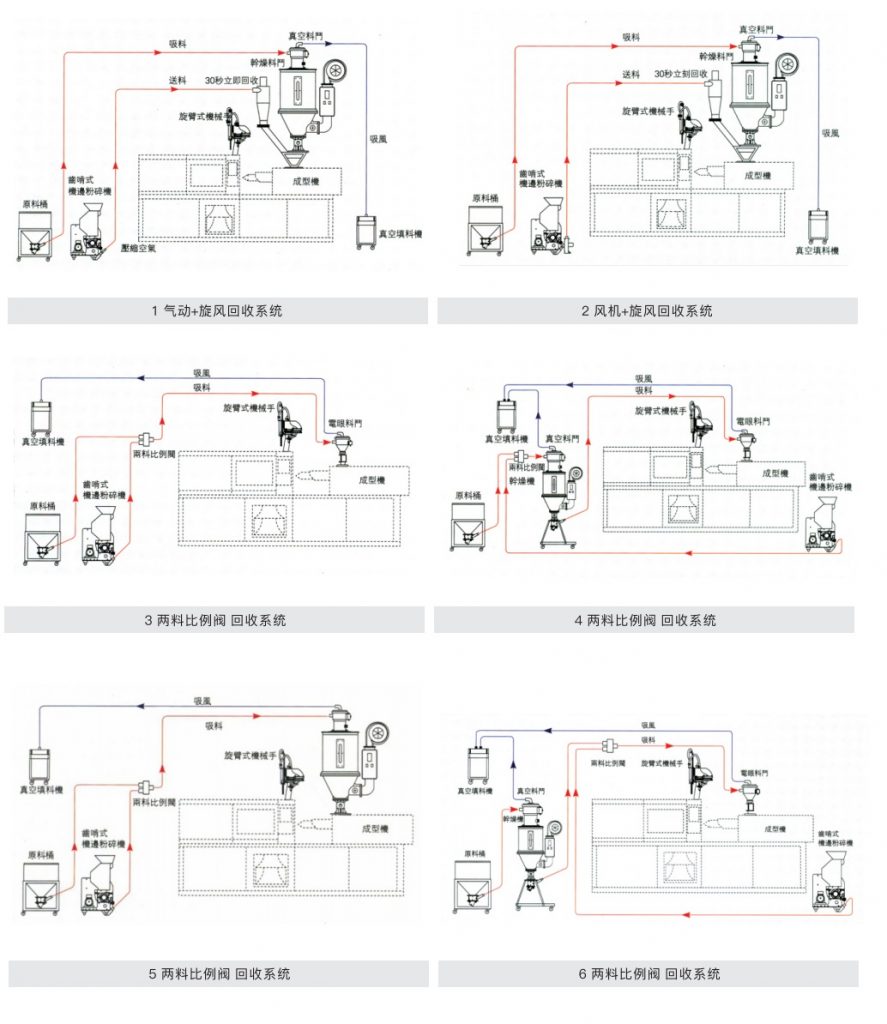

Installation Layout:

Maintenance and Safety Measures

Proper maintenance practices for the machine

Proper maintenance practices are essential for ensuring the efficient and safe operation of a universal grinder. Here are some maintenance practices that should be followed:

- Regular cleaning – The machine should be cleaned regularly to remove any debris, dust, or coolant that may accumulate on the machine’s surfaces. This can be done using a soft brush, air hose, or a cleaning solution.

- Lubrication – The machine’s moving parts should be lubricated regularly to reduce friction and wear. The manufacturer’s recommendations for lubrication intervals and types should be followed.

- Inspection – The machine should be inspected regularly for any signs of wear, damage, or misalignment. Any issues should be addressed immediately to prevent further damage or safety hazards.

- Replacement of worn or damaged parts – Worn or damaged parts should be replaced immediately with genuine parts from the manufacturer.

- Calibration – The machine should be calibrated regularly to ensure that it is operating within the specified tolerances and accuracy.

- Operator training – Proper operator training is essential for ensuring the safe and efficient operation of the machine. Operators should be trained on the proper operation, maintenance, and safety procedures for the machine.

- Record keeping – A maintenance log should be kept to track the machine’s maintenance history, including cleaning, lubrication, inspection, and repairs. This can help identify any trends or issues that need to be addressed.

Following these maintenance practices can help ensure the safe and efficient operation of a universal grinder, prolong its lifespan, and reduce the risk of downtime and costly repairs.

Safety measures for operators and workers

Safety measures for operators and workers are crucial when using a universal grinder. Here are some safety measures that should be followed:

- Personal protective equipment (PPE) – Operators and workers should wear appropriate PPE, including safety glasses, hearing protection, gloves, and safety shoes.

- Machine guards – The machine should be equipped with proper machine guards to prevent access to the grinding wheel during operation. The guards should be in good condition and properly installed.

- Lockout/tagout procedures – Lockout/tagout procedures should be followed to ensure that the machine is not accidentally started or energized during maintenance or repair.

- Training – Operators and workers should receive proper training on the safe operation of the machine, including the use of PPE, machine guards, and lockout/tagout procedures.

- Inspection – The machine should be inspected regularly for any signs of wear, damage, or misalignment that may pose a safety hazard.

- Proper use of grinding wheels – Operators should ensure that the grinding wheel is properly installed, dressed, and aligned. The grinding wheel should not be overloaded or forced into the material being ground.

- Proper handling of coolant – If coolant is used, operators should ensure that it is properly mixed, applied, and contained. Coolant should not be allowed to accumulate on the floor, as it can create a slipping hazard.

- Emergency procedures – Emergency procedures should be established and communicated to all operators and workers in case of an accident or injury.

Following these safety measures can help prevent accidents and injuries when using a universal grinder. It is important to prioritize safety and ensure that all operators and workers are trained and informed about the potential hazards of the machine.

Industrial Dry and Wet Grinder:

A dry grinder and a wet grinder are two types of kitchen appliances that are used for different purposes. A dry grinder is used to grind dry ingredients such as spices, coffee beans, nuts, and grains. It operates without any water or liquid, making it perfect for dry ingredients. On the other hand, a wet grinder is used to grind wet ingredients such as soaked grains, lentils, and vegetables to make batter, chutneys, and masalas. It uses water or other liquids to help with the grinding process. Wet grinders are commonly used in Indian cuisine, where wet masalas and batters are frequently prepared. Both types of grinders are handy kitchen appliances that save time and effort in the kitchen.

Industrial Dry Spice Grinder:

A dry spice grinder is a kitchen appliance that is used to grind dry spices and herbs. It is a must-have tool for any home cook or professional chef who loves to use freshly ground spices for flavoring their dishes. A dry spice grinder typically consists of a small container with a rotating blade at the bottom. The blade chops and grinds the spices into a fine powder or a coarse texture, depending on the desired result.

Dry spice grinders come in various shapes and sizes, from handheld manual grinders to electric grinders with multiple settings. Some models also come with detachable containers for easy cleaning and storage. The most common spices that are ground using a dry spice grinder include black pepper, cumin, coriander, cinnamon, and nutmeg.

Using freshly ground spices instead of pre-ground ones adds a burst of flavor to any dish. A dry spice grinder allows you to customize the texture and coarseness of the spice blend to suit your recipe. It is a versatile tool that can also be used to grind coffee beans, nuts, and grains.

Best China Automatic Industrial Electric Dry Herb Grinder:

A dry herb grinder is a tool used to grind dried herbs and spices, such as oregano, thyme, basil, rosemary, and more. The grinder is designed to break down the herb into smaller, more manageable pieces, which can then be used in cooking, baking, or even for medicinal purposes.

Most dry herb grinders have a cylindrical shape, with two interlocking halves that are held together by magnetic or screw-on fastenings. The top half usually has sharp teeth, while the bottom half has a collection chamber that holds the ground herbs. The grinder is operated by twisting the two halves in opposite directions, which causes the teeth to shred the herbs into small pieces.

One of the main benefits of using a dry herb grinder is that it helps to release the natural oils and flavors of the herbs. This enhances the aroma and taste of the herbs, making them more potent and flavorful. In addition, grinding the herbs allows them to be more easily incorporated into recipes, as they can be more evenly distributed throughout the dish.

Dry herb grinders come in a variety of materials, such as metal, plastic, and wood. They also come in different sizes, ranging from small pocket-sized grinders to larger tabletop models. When choosing a dry herb grinder, it is important to consider the material, size, and durability of the grinder, as well as any additional features, such as a kief catcher or pollen screen.

Industrial Dry Food Grinder:

A dry food grinder is a kitchen appliance used to grind a variety of dry foods, such as grains, nuts, seeds, and spices, into a fine or coarse powder. This appliance can be a manual or electric device that usually features a motor, blades or burrs, and a hopper where the food is fed into.

Dry food grinders can be used for many purposes, such as grinding coffee beans, making flour from grains, crushing nuts and seeds for nut butter or spreads, and creating spice blends for cooking. They are an essential tool for home cooks and professional chefs who seek to incorporate fresh, high-quality ingredients into their recipes.

The type of dry food grinder chosen will depend on the intended use. A manual grinder, for example, is a good option for grinding small quantities of spices, while an electric grinder can handle larger amounts of food in less time. Some dry food grinders also have adjustable settings for controlling the texture of the grind.

Dry food grinders are typically made from durable materials such as stainless steel, plastic, or ceramic. Some models come with multiple attachments, such as various blades or burrs, to allow for more versatility in the types of foods that can be ground. Care and maintenance of the grinder will vary depending on the model, but most can be easily disassembled for cleaning and some are even dishwasher safe.

Overall, a dry food grinder is an excellent addition to any kitchen for those looking to enhance the taste and quality of their cooking by using fresh, whole ingredients.

Industrial Dry Pepper Grinder

A dry pepper grinder is a kitchen tool designed to grind dried peppercorns into a fine powder or a coarser texture for use in cooking and seasoning dishes. Pepper grinders can be manual or electric, and come in a range of styles, from traditional wooden models to sleek, modern designs.

Pepper grinders are used to release the aromatic oils and flavors of dried peppercorns, which adds a distinctive taste and aroma to food. Peppercorns are available in a range of colors, including black, white, green, and pink, with each color having its own unique flavor and intensity.

Dry pepper grinders generally feature a cylindrical shape, with a mechanism for grinding the peppercorns located at the top or bottom of the grinder. Manual pepper grinders require the user to turn a crank or twist the top to grind the peppercorns, while electric pepper grinders operate with the push of a button.

When choosing a dry pepper grinder, it’s important to consider factors such as the size, material, and durability of the grinder. Some models come with multiple grinding settings, allowing for the adjustment of the coarseness of the grind, while others are designed to hold large quantities of peppercorns for easy refilling.

In addition to peppercorns, dry pepper grinders can also be used to grind other dried spices and herbs, such as cumin, coriander, and fennel. Proper maintenance of the grinder is essential to ensure that it functions properly and lasts a long time. Most pepper grinders can be easily disassembled for cleaning and some are even dishwasher safe.

Overall, a dry pepper grinder is an essential tool in any kitchen, providing the ability to add fresh, flavorful pepper to dishes with ease.

Universal Grinder Youtube Video (See More)

About LKMixer

LKMixer is a professional manufacturer for fertilizer production line, grinder, mixer and granulator, shredder. These machines are widely used in food, pharmaceutical, cosmetic, health care products and chemical industries. The Food materials like Peanut, mushroom, seeds, potato, bean, tobacco, salt, cannabis, tea, Sugar, corn, Coffee, rice, pepper, grain as so on. Grinders have many types such as Pulse Dust Grinder which suitable for zero pollution environment, Turbine Mill which is suitable for coffee bean, 12-120mesh all can meet, Ultrafine Grinding Mill covers 80-200mesh, and also Winnowing Dust Grinder or other grinding machines like SF Hammer. Welcome to contact us for details. Contact us for more information. Proposal, catalog, quotation. Mobile/WhatsApp: +86 18019763531 Tel: +86 21 66037855 Email: sales@lkmixer.com

Contact Us

FAQ(Click and See More)

What is the difference between a cylindrical grinder and a universal grinder?

A cylindrical grinder and a universal grinder are both types of grinding machines, but there are some differences between them.

A cylindrical grinder is a machine tool that is used to shape the outside of an object. It has a wheel that rotates on a horizontal axis and the object is held in place between a center and a chuck. The object is rotated and the grinding wheel removes material from the outside surface of the object. Cylindrical grinders are typically used to create round shapes, such as cylinders or cones, and they are commonly used in manufacturing and metalworking industries.

A universal grinder, on the other hand, is a type of cylindrical grinder that can perform a variety of grinding operations. In addition to the cylindrical grinding capabilities of a standard cylindrical grinder, a universal grinder can also perform internal grinding, centerless grinding, and other types of grinding operations. This is achieved through the use of additional attachments and accessories that can be fitted to the machine.

In summary, while a cylindrical grinder is designed specifically for shaping the outside of an object, a universal grinder is designed to perform a wider range of grinding operations, including internal grinding and centerless grinding.