Dust Collector Grinder 60-3000kg/h 20-120 mesh WFD

WFJ Series Pulse Dust Grinder Group

- Production Capacity:60-3000kg/h

- Feeding Size: 6-15mm

- Crushing fineness:20-120mesh

- Spindle speed:1500-4500mm

- Crushing Motor power: 4-55kw

- Machine Weight:580-6000kg

| Mode | 1 Unit (FOB USD) | 5 Units (FOB USD) |

| WFJ-400 | 12000 | 10800 |

| WFJ-600 | 17538 | 15785 |

| WFJ-800 | 28615 | 25754 |

| WFJ-1000 | 46154 | 41538 |

| WFJ-1200 | 52615 | 47354 |

WFJ Dust Collector Grinder Introduction:

This Dust Collector Grinder machine is suitable for pharmaceutical, chemical, food, magnetic materials, powder, etc., is crushing, vacuuming and continuous discharge as one of the new generation of grinding equipment.

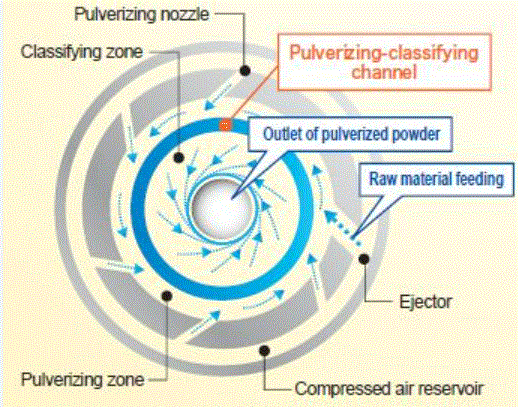

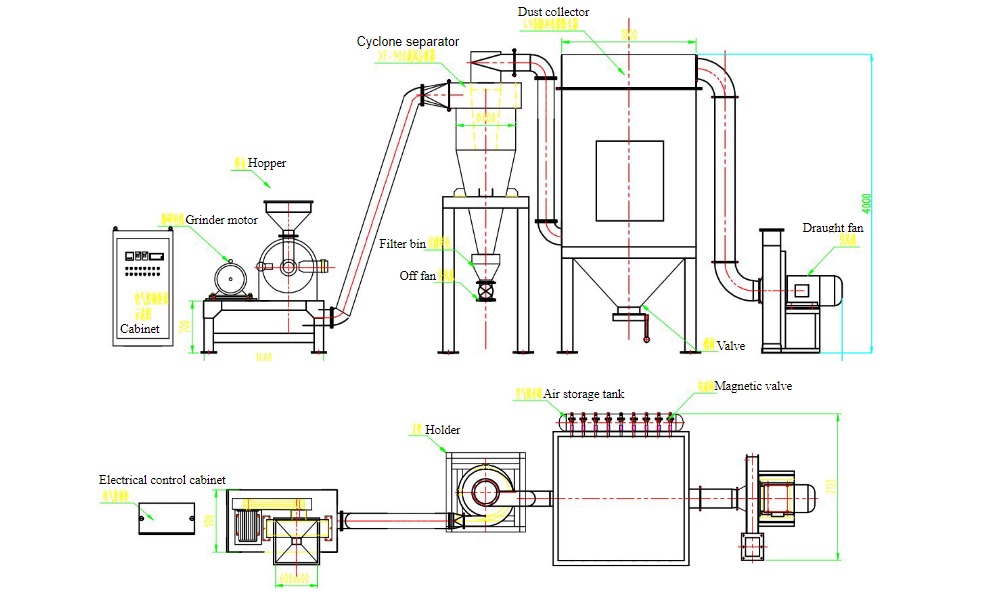

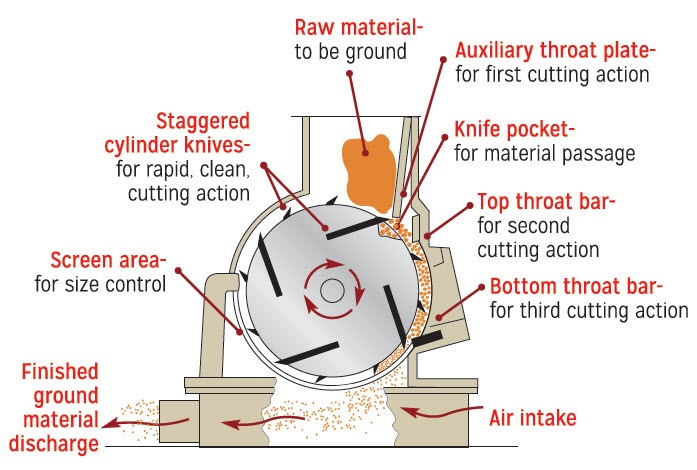

WFJ Dust Collector Grinder Working Principle:

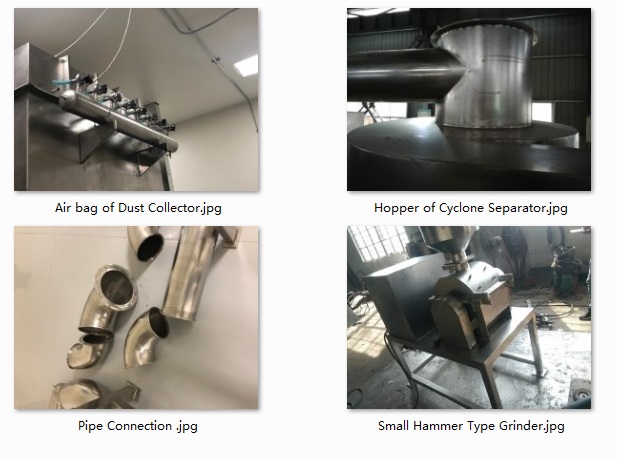

The machine consists of mill, cyclone separator, dust boxes and pulse a few fans and other major components. The aircraft is the use of activity and fixed gear chainring relative motion between the plate so that the material was crushed by the teeth impact, friction and impact between the material to obtain crushed, crushed by the rotating centrifuge good material and fan of gravity, into the whirlwind Separator discharge, and then by the fan off, dust into the pulse dust box, through the filter cartridges and recycling, crushing fineness sieve adjustment. Machine according to GMP standard design, all with stainless steel, no dust in the production process.

WFJ Dust Collector Grinder Technical Parameters:

| Model | 2 0 B Ⅳ、Ⅴ、Ⅵ | 3 0 B Ⅳ、Ⅴ、Ⅵ | 4 0 B Ⅳ、Ⅴ、Ⅵ | 6 0 B Ⅳ、Ⅴ、Ⅵ | 8 0 B Ⅳ、Ⅴ、Ⅵ | 1 0 0 B Ⅳ、Ⅴ、Ⅵ |

| Production Capacity | 60-150 | 100-400 | 160-800 | 400-1500 | 600-2000 | 1000-3000 |

| Spindle speed (r/min) | 4500 | 3800 | 3400 | 2800 | 2200 | 1500 |

| Feeding Size (mm) | 6 | 6 | 10 | 12 | 15 | 15 |

| Crushing fineness (mesh) | 20-120 | 20-120 | 20-120 | 20-120 | 20-120 | 20-120 |

| Crushing Motor (kw) | 4 | 5.5 | 11 | 22 | 37 | 55 |

| Dust collecting motor (KW) | 2.2 | 3 | 4 | 7.5 | 15 | 18.5 |

| Discharge Motor (kw) | 0.37 | 0.55 | 0.55 | 0.75 | 1.5 | 2.2 |

| Dimension(mm) | 3000 × 850 × 2300 | 3500 × 850 × 2380 | 5830× 1100× 2800 | 5830 × 1300× 3150 | 8550 × 2120× 4000 | 9980 × 1280× 2800 |

| Weight (kg) | 580 | 880 | 1200 | 2000 | 3000 | 6000 |

Pulse Dust Grinder Knife

Pulse Dust Grinder Screen:

Screen Material: Support 304, 316 stainless steel screen customization.

Screen mesh: Support mesh size customization.

Shipment Picture:

About LKMixer

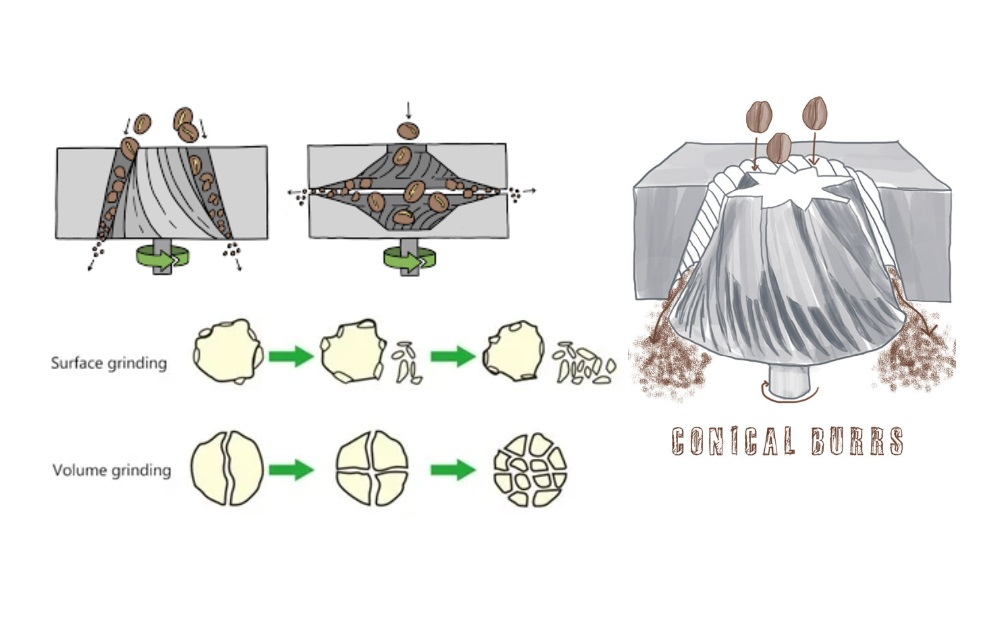

LKMixer is a professional manufacturer for fertilizer production line, grinder, mixer and granulator, shredder. These machines are widely used in food, pharmaceutical, cosmetic, health care products and chemical industries. The Food materials like Peanut, mushroom, seeds, potato, bean, tobacco, salt, cannabis, tea, Sugar, corn, Coffee, rice, pepper, grain as so on. Grinders have many types such as Pulse Dust Grinder which suitable for zero pollution environment, Turbine Mill which is suitable for coffee bean, 12-120mesh all can meet, Ultrafine Grinding Mill covers 80-200mesh, and also Winnowing Dust Grinder or other grinding machines like SF Hammer. Welcome to contact us for details. Contact us for more information. Proposal, catalog, quotation. Mobile/WhatsApp: +86 18019763531 Tel: +86 21 66037855 Email: sales@lkmixer.com

Contact Us

Food Grinder:

| Mode/Item | WF- universal grinder | FL Series Air Cooled Crusher | B Series Vacuum mill group | WF series pulse dust grinder group | WFJ dyadic type turbine pulveriger | GFSJ series High Efficient Mill | WFJ-Chinese medicine grinder | WF-winnowing dust grinder | SF – hammer mill | CSJ Series High Coarse Crusher |

| food grinder | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| cereal | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| corn | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| rice | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| Millet | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| chili | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| Sunflower | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| ginger | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| Wheat oil | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| soybean | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| white sugar | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| salt | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| starch, | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| oat, | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| flour | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| pea, | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| lentils | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| green beans, | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| spices, | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| Flavors and Fragrances | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| sweetener | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| dried fruit | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| potato chips, | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| crumbled bread, | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| cocoa powder, | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| potato flour | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| coffee, | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| milk powder | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| onion | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| lotus seeds | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| glucose | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| oat husk | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| husk | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| star anise | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| nut | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| coffee beans | √ | √ | √ | √ | √ | √ | √ | √ | √ | |

| root class | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| Diameter | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| black pepper | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| soybean meal | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| garlic | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| dehydrated vegetables | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| hawthorn | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| garlic slices | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| dried ginger | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| saccharin | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| food | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| shrimp skin | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| pumpkin powder | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| seasoning | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

Recommend Reading

- Licorice root powder benefits

- Licorice Flavored Spice Types

- Carrot Processing Line Drying Grinding

- Green Bean Production Line

- Spice Pepper Drying Grinding Production Line

Recommend Products

Recover

Air Cooled Crusher

- Production Capacity:30-2200kg/h

- Feeding Size: ≤ 5 or ≤ 10

- Crushing fineness:30-120mm

Recouperate

High Coarse Crusher

- Production Capacity:10-2200kg/h

- Feeding Size:≤ 100

- Crushing fineness:0.5-20

Recover

Universal Grinder

- Production Capacity:20-3500kg/h

- Feeding Size:6-15mm

- Crushing fineness:10-150mm

Recouperate

Pulse Dust Grinder

- Production Capacity:20-3500kg/h

- Feeding Size:6-15mm

- Crushing fineness:10-150mm