My Grinder is Stuck

Customer always calls for help: My Grinder is Stuck, or my grinder always get clog, Why is my grinder hard to turn? Why is my grinder jamming? Why my grinder is not working? If your grinder keeps getting stuck, there are several potential causes that you should investigate. Take coffee bean for example, no matter small coffee bean grinder or large industrial coffee bean grinder, all will meet this problem. The solution are also similar.

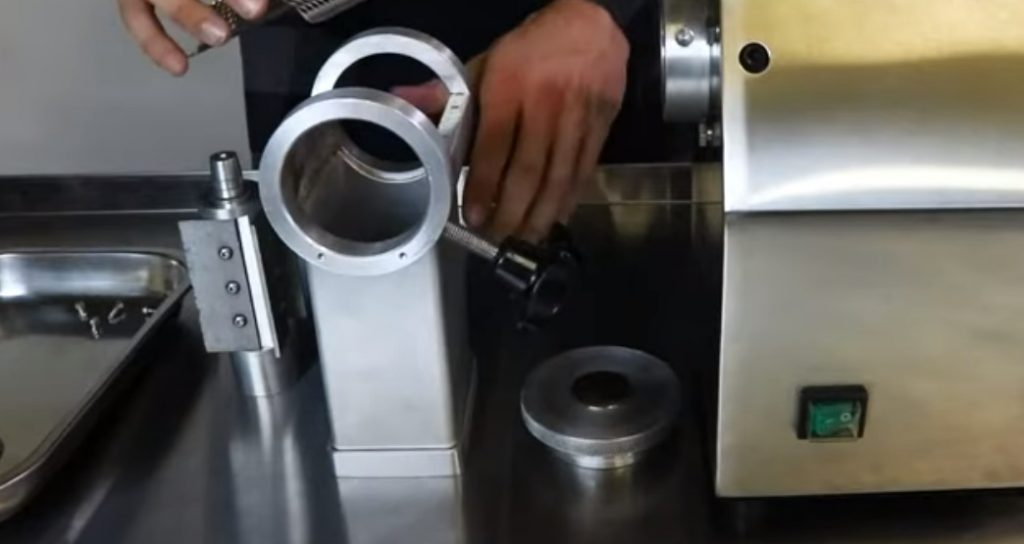

For instance, as following picture shows, when the grinding machine cutting the flax seed for a period of time, the seeds material will stick onto the wall and cutting knife because of oil content:

What Causes a Grinder to Get Stuck?

A grinder can get stuck for several reasons. The most common cause is a buildup of plant matter or debris inside the grinder. As you use your grinder, small pieces of herb or cannabis can get trapped between the teeth, causing it to become clogged. The clogged grinder can make it difficult or even impossible to turn.

Another reason why your grinder may get stuck is that the teeth have become dull or damaged over time. The teeth on a grinder are designed to cut through plant matter with ease. But with prolonged use, the teeth can become blunt or damaged, making it difficult to grind up your herbs. There are also many other problems such as the temperature goes over heat, if you are planning to buy the new machine, you can customize from the very beginning to do best to prevent this issue.

If you didn’t buy the grinder yet. The best way to prevent or reduce the chance of getting stuck is to choose the right grinding machine. That is to say to choose the grinder which is not easy to get stuck:

This is very important, different structure will leads to different effectiveness. If the structure is reasonable, it will be not easy to go stuck. Especially for oily material, it is hard to transport in pipes, and also sticky. When goes through the pipe or screen, the oily material powder is easy to stick on the wall of pipe, and accumulate until stuck the pipe. Many customers feedback their old grinder stuck and ask for improvement in new machine production. This is really important to choose the right model of grinder at the very beginning. For example, baked coffee bean and un-roasted coffee bean should choose the different model. If contains water, choose turbo type of grinder, but if dried material like spices or condiments, should choose the Super fine grinder. We can adopt various method to avoid the stuck of material in the grinding machine or pipe, therefore to increase the output capacity of grinding.

A. For example, Bottom pipe is more easy to get materials clog in grinding process, while side pipe is not easy to get clogged.

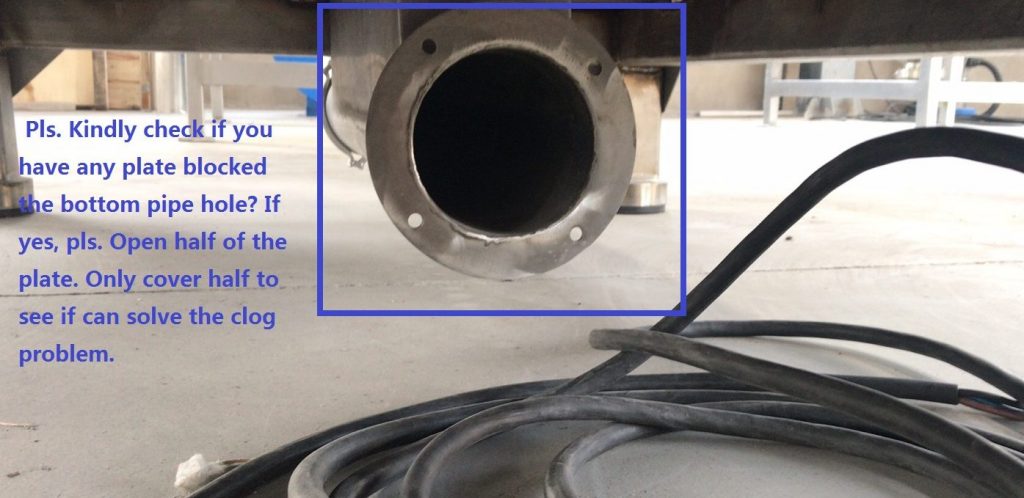

Customer Problem: The bottom pipe is always getting clogged. We will need to have air nozzles added to the bottom pipe and the pipe that goes to the silo. By blasting air every 10 minutes this will prevent the pipes and the silo from getting clogged up. We will need some kind of simple timer attached to the air that will be blasted through the system.

How to solve: We have other customer the same problem as you, because of their material is heavy and easy to be clogged. Please kindly check if you have any plate blocked the bottom pipe hole? If yes, please open half of the plate. Only cover half to see if can solve the clog problem. Other customer opened half of the plate and solved problem, no more clog again. Please kindly ask your engineer to have a try. Maybe can solve the problem and no need to add an air nozzle.

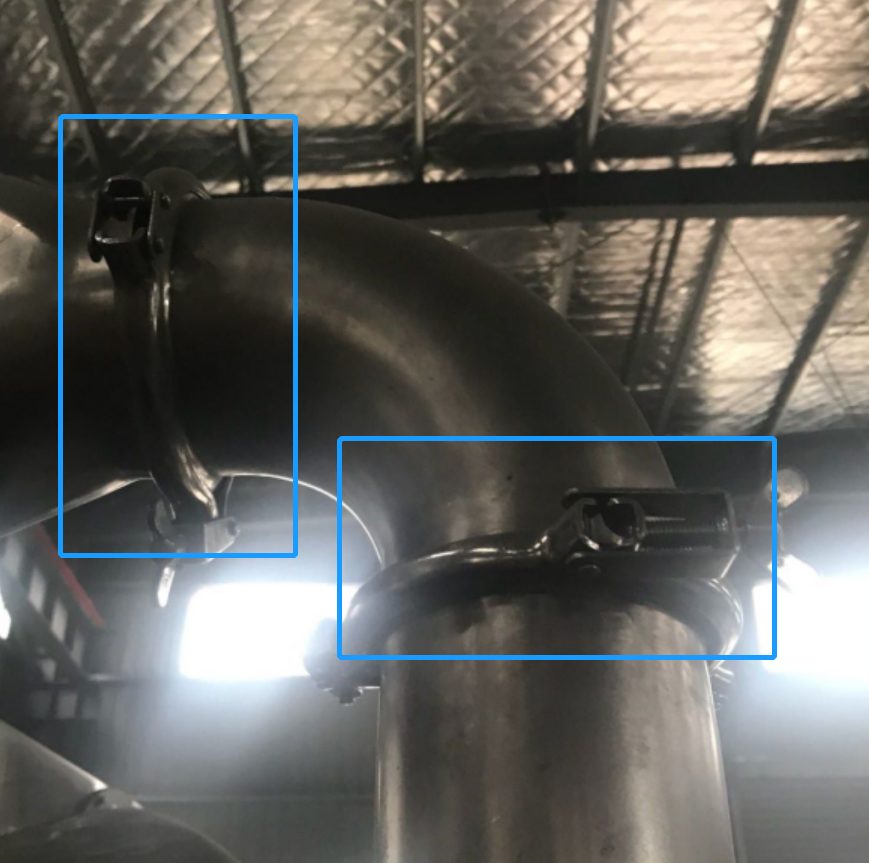

B. To prevent the Clog of output, to use the Air hammer, it taps the cyclone separator every few minutes; it helps prevent discharge block, promote output effectiveness and prevent the stuck of material.

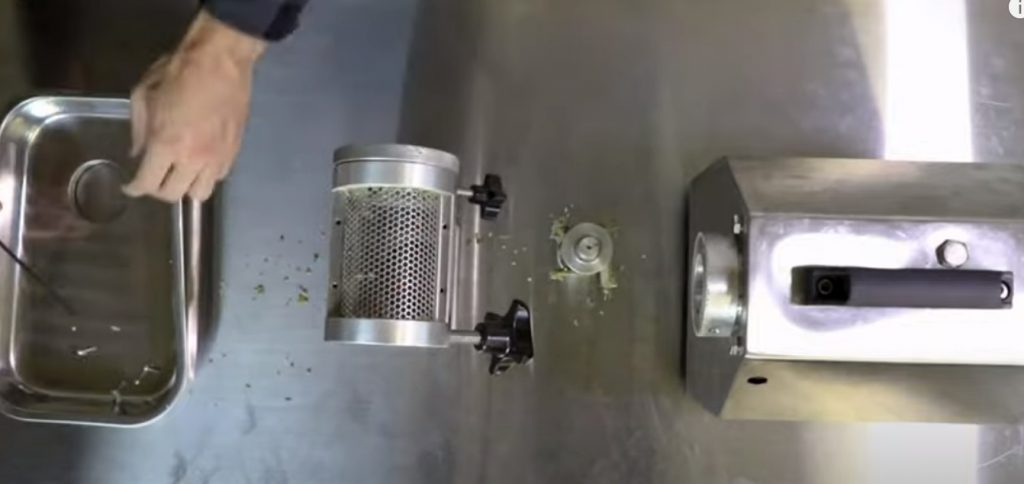

C. To customize the grinder machine easy to take apart and easy to clean:

To know that no matter what kind of mechanical equipment, after a long time of use, it is need to carry out maintenance work. The crusher and grinder equipment are the same. Therefore, it is necessary for us to follow up the corresponding cleaning work, many users may not be very understanding of this. They may ask why do you need to clean your crusher equipment regularly? Because the machine will produce some dust and material residue in the process of production work, and these dust and material residue may accumulate and settle inside the equipment, such as ventilation pipes, crushing chambers, component surfaces, etc., which will directly affect the use of the equipment. More serious, it may cause a series of failures and problems. So we need to cleaning the machine at regular intervals.

Under normal circumstances, every time the production work of the machine needs to be cleaned up for a week. After a month, large-scale maintenance is needed. If the grinder is a long time and high intensity production work, then you need to shorten the maintenance and maintenance cycle appropriately. And before each production work is ready to start, Firstly, let the staff conduct a comprehensive inspection of the equipment to ensure that the machine is in a good state of production work, to ensure that the subsequent production work can be carried out smoothly without encountering problems. Here we also list down some solution for solving the stuck:

All the pipes are connected by quick valve, this makes the whole machine easy to take apart for cleaning. and the cyclone separator can be taken apart.

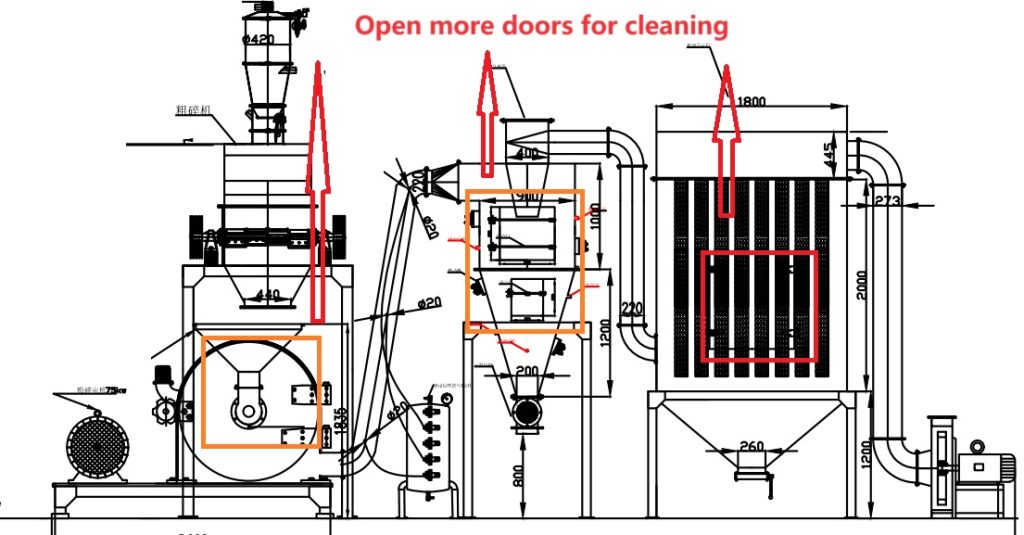

D. To open more doors for cleaning, open doors for cleaning the material is more easy to clean when pipes get stuck.

Doors can opened at the door of grinding head, dust collector and cyclone separator. For the pipe can separated to be several items.

Grinder not easy to stuck for sale: Contact us to customize your grinding machine.

II. The Second Solution is: Clean the Grinder (Click to see more about how to clean grinder)

Often, a grinder gets stuck because it’s clogged with plant matter or debris. Disassemble the grinder and clean it thoroughly with a brush or toothbrush. Make sure to remove all debris from the teeth, screen, and walls. You can also use a small, soft-bristled brush to sweep away any remaining plant matter.

To clean your grinder, start by disassembling it into its various parts. You should be able to separate the top, middle, and bottom sections of the grinder. Remove the lid and use a toothbrush or a small brush to remove any debris or plant matter that may be stuck on the teeth or in the crevices.

You can also use rubbing alcohol to help remove any stubborn debris. Soak the grinder in rubbing alcohol for a few minutes, then use a brush to scrub away any remaining plant matter. Rinse the grinder thoroughly with warm water and let it dry completely before reassembling it.

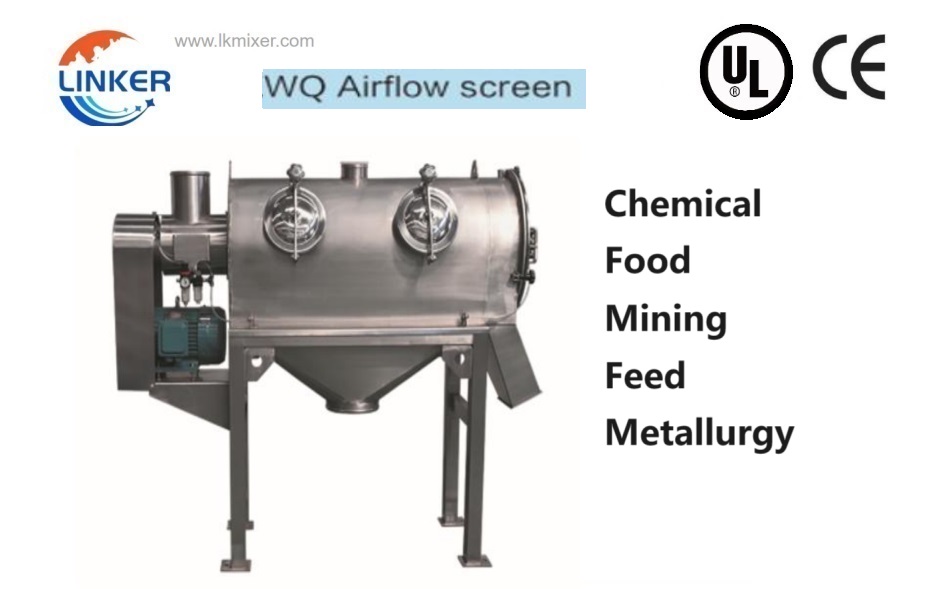

About LKMixer

LKMixer is a professional manufacturer for fertilizer production line, grinder, mixer and granulator, shredder. These machines are widely used in food, pharmaceutical, cosmetic, health care products and chemical industries. The Food materials like Peanut, mushroom, seeds, potato, bean, tobacco, salt, cannabis, tea, Sugar, corn, Coffee, rice, pepper, grain as so on. Grinders have many types such as Pulse Dust Grinder which suitable for zero pollution environment, Turbine Mill which is suitable for coffee bean, 12-120mesh all can meet, Ultrafine Grinding Mill covers 80-200mesh, and also Winnowing Dust Grinder or other grinding machines like SF Hammer. Welcome to contact us for details. Contact us for more information. Proposal, catalog, quotation. Mobile/WhatsApp: +86 18019763531 Tel: +86 21 66037855 Email: sales@lkmixer.com

Contact Us

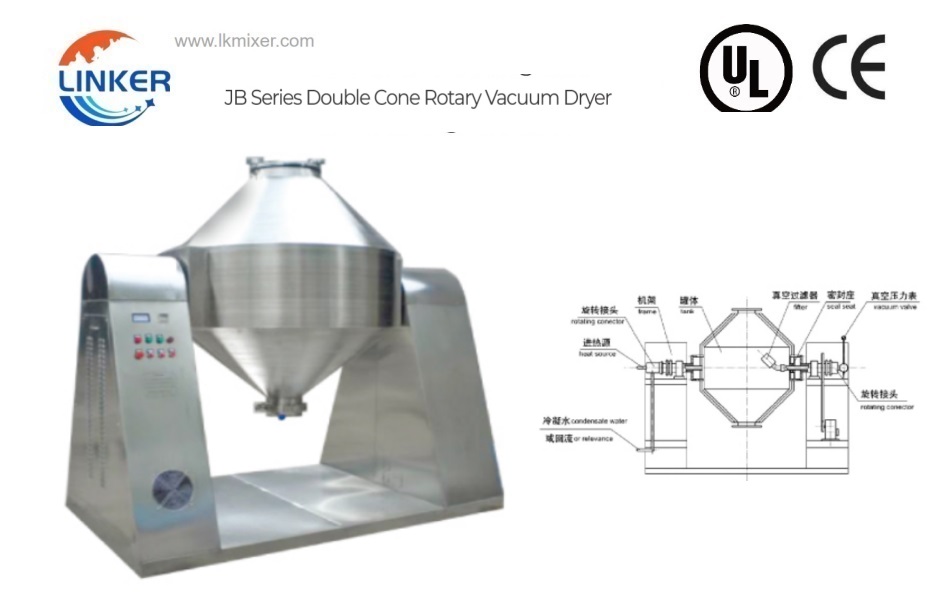

III. The Third Solution: Freeze the Grinder (To add Air cool system or Liquid nitrogen freezing system):

There are 3 ways of cooling down the grinder: water cooling system; air cooling system and liquid nitrogen freezing system. You can choose the right one if the grinder gets too hot. When machines goes too hot, the metal can expand, causing the grinding wheel to get stuck. Another method to fix a stuck grinder is to place it in the freezer for 15-20 minutes. The cold temperature can cause any stuck plant matter to become brittle, making it easier to remove. Once the grinder is cold, tap it gently on a hard surface to loosen any remaining debris. You can also use a soft-bristled brush to sweep away the debris.

Freezing the grinder can also help you collect any material that may be stuck to the grinder’s walls. material is a concentrated form of cannabis that contains high levels of THC. It’s the powdery substance that collects in the bottom chamber of a grinder.

When you freeze the grinder, any material that’s stuck to the walls will become brittle and easier to collect. Use a small brush or a toothbrush to remove the material gently. You can then use the kief to sprinkle on top of your bowl or add to your joint to increase its potency.

Add Air cool system:

Cryogenic Grinding Machine

IV. The Fourth Solution: Tap the Grinder, add air hammer is actually tap the grinder to prevent clog to some extents. This is a way to reduce the clog, but not the solution of solve the root cause.

After freezing, tap the grinder gently on a hard surface to loosen any remaining debris. Hold the grinder upside down and tap the bottom gently against a hard surface. This will help to dislodge any stubborn plant matter that’s stuck inside.

You can also use a soft-bristled brush to sweep away any remaining debris. Be careful not to apply too much pressure as this can damage the teeth or screen.

V. Use a Tool

If tapping and brushing don’t work, you can use a tool like a toothpick or needle to remove any stubborn plant matter. Be careful not to damage the machine.

If you already bought the grinder, but it keeps getting stuck, you need to check the reason why it goes stuck and remove the problems: (here takes herb grinder for example)

A grinder is an essential tool for any cannabis or herb enthusiast. It’s designed to grind up your buds or herbs into small, uniform pieces that are perfect for rolling into joints or packing into bowls. However, there may be times when your grinder gets stuck, and you find it challenging to turn. In this article, we’ll explore what causes a grinder to get stuck and what you can do to fix it. If your grinder is stuck and you’re having difficulty turning it, there are several things you can try to fix it.

Grinding is a crucial part of many industrial processes, and a grinder is an essential tool for many businesses. Grinders are used to remove excess material from workpieces, sharpen blades and tools, and create fine finishes on surfaces. However, one of the most common problems with grinders is that they can get stuck, which can cause significant downtime and lost productivity.

To identify the cause of your grinder getting stuck, it’s important to start by inspecting the machine and its components. Here are some steps you can take to troubleshoot the issue:

1. To Check the Grinding Wheel and grinding knife, screens:

The grinding wheel and grinding knife are the most critical components of a grinder, and it’s often the source of problems when the machine gets stuck. If the cutting knife is dull or worn, it can’t efficiently grind the material, leading to increased friction and heat buildup. As a result, the wheel can get stuck or even break. Inspect the grinding wheel carefully and look for signs of wear or damage, such as cracks or chips. If the wheel is worn or damaged, it should be replaced immediately.

Clean the Grinding Wheel, change the cutting knife and screens:

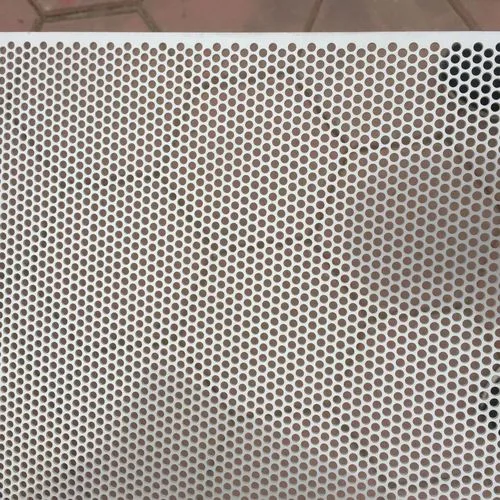

Another common reason for a grinder to get stuck is that the wheel is clogged with debris, such as metal shavings or dust. This debris can accumulate over time and impede the grinder’s ability to grind effectively. To clean the wheel, turn off the grinder and unplug it from the power source. Use a wire brush or compressed air to remove any debris from the wheel’s surface. Be sure to wear protective gear, such as gloves and eye protection, when cleaning the wheel.

Screens are used to filter, this is insert in machine wheel, to change it on time can avoid the clog.

Check for Overheating

As mentioned before, There are 3 ways of cooling down the grinder: water cooling system; air cooling system and liquid nitrogen freezing system. This is especially common when grinding. Check the grinder’s manual to see if it has a recommended duty cycle or if there are any other precautions you should take to prevent overheating. Also, make sure that the grinder has proper ventilation to help dissipate heat. You can use cooling fan or air cool system to cool down the machine.

Check the Grinding Wheel Type

The type of grinding wheel you’re using can also impact how well the grinder operates. For example, if you’re trying to grind a hard material with a soft grinding wheel, the wheel will wear down quickly and get stuck. Make sure that you’re using the correct type of grinding wheel for the material being ground.

Check the Bearings (Click to see more about the Safety of running grinder)

The bearings in a grinder are responsible for supporting the grinding wheel and keeping it running smoothly. Over time, the bearings can wear down or become damaged, causing the wheel to get stuck. To check the bearings, turn off the grinder and unplug it from the power source. Use a wrench to remove the grinding wheel and inspect the bearings for signs of wear or damage. If the bearings are worn or damaged, they should be replaced.

Clean the Pipes:

Clean each pipes to make sure no clog and accumulate of material on wall of pipes.

All in All, If you still in researching process of buying new grinding machine, please be patient to find the very right model. Actually material clog mostly happen when you grind in very large quantity and especially the oily material easy goes stuck. If your material is not oily material, this problem should not be the critical issue. If you already have grinding machine and always goes stuck, you need to know the reason and improve the machine if possible, and keeps cleaning the machine to make it more efficiently.

How to Customize Grinder not easy go stuck:

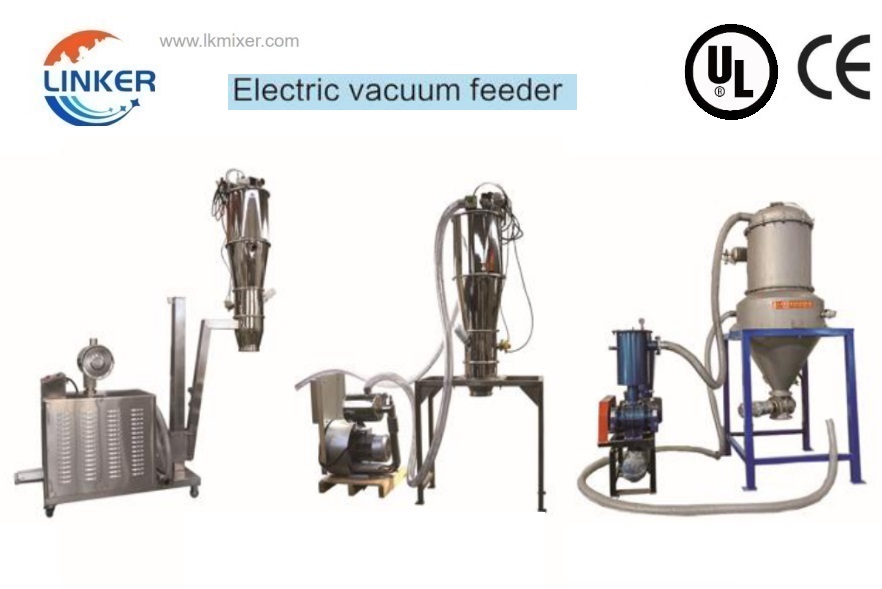

We can customize the capacity according to your special requirement, we can also customize the vacuum feeder connect with your production line (the dimension and width of grinder), for detail contact with our sales for proposal and price.

Videos of Grinder Machine:

Many model of Grinder, the universal grinder is suitable to cut the materials into 12-120mesh, the high efficient grinder is useful, but cost a little bit higher than universal. The super fine grinder can grind into 100mesh to 320mesh. Customer can choose according to your own requirement. here show some example: