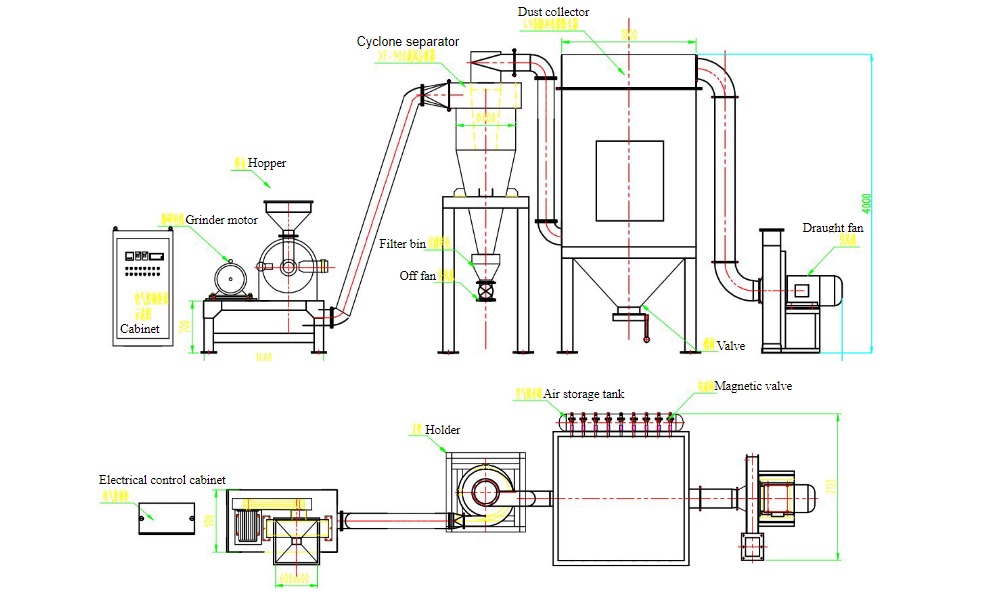

Grinder Application

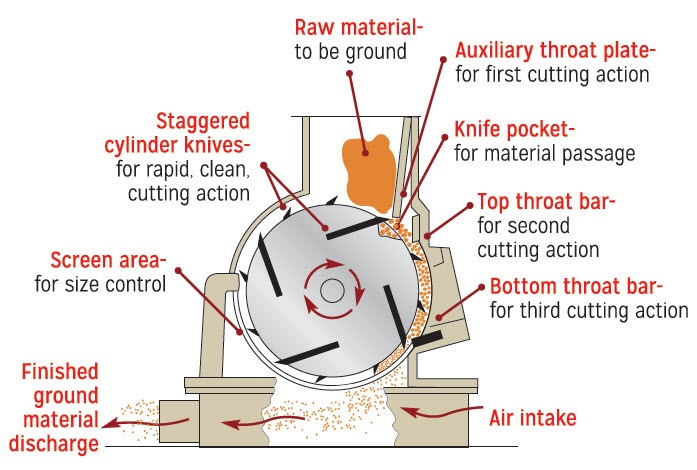

Grinder Application is very wide. Grinding mill, pulverizer and crusher, shredders are all widely used in all industries, such as food , chemical, pharmaceutical, medicine and so on.

Food Processor: (Size and Capacity can be customized)

Plastic recycling Industry:

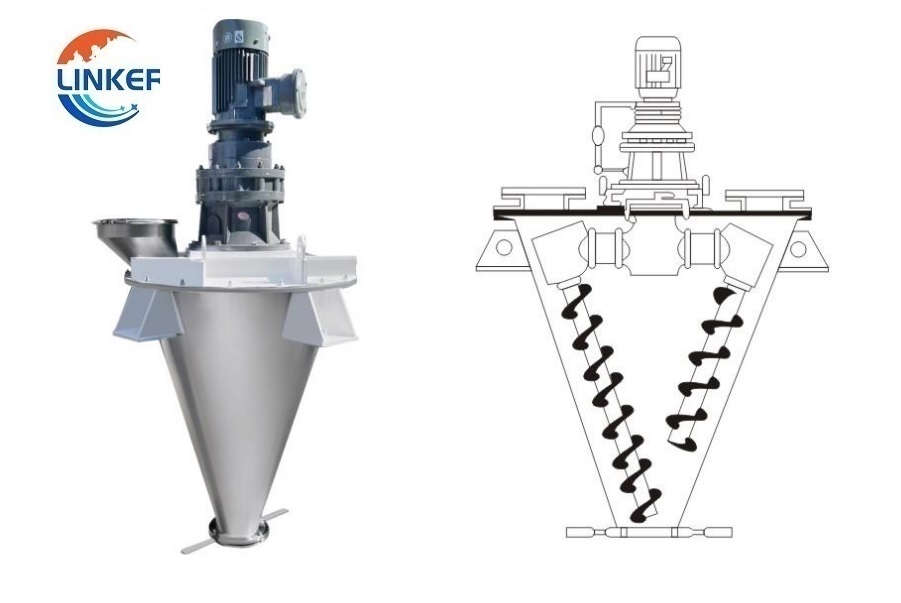

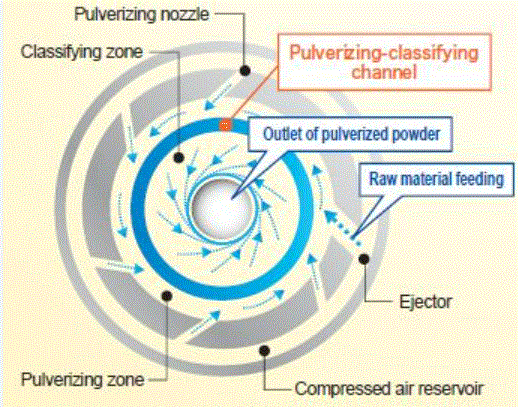

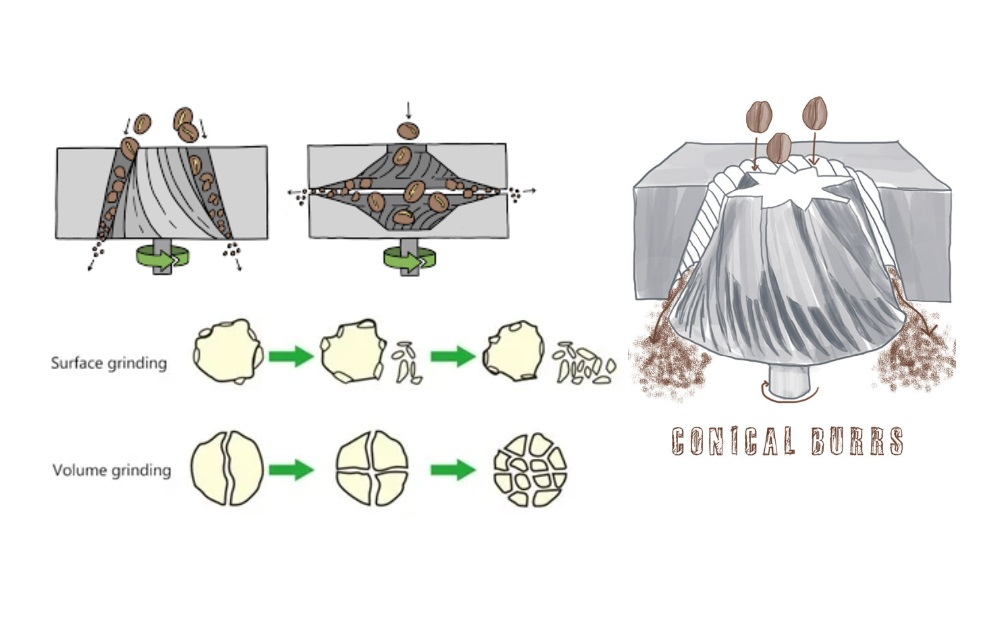

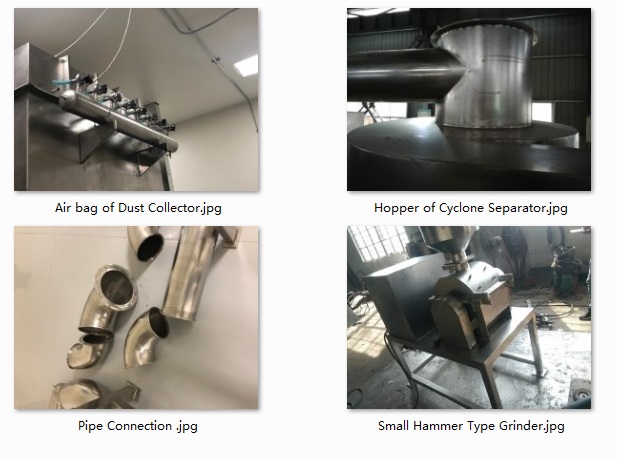

Grinder & pulverizer: (Size and Capacity can be customized)

Plastic Shredder for Sale Video

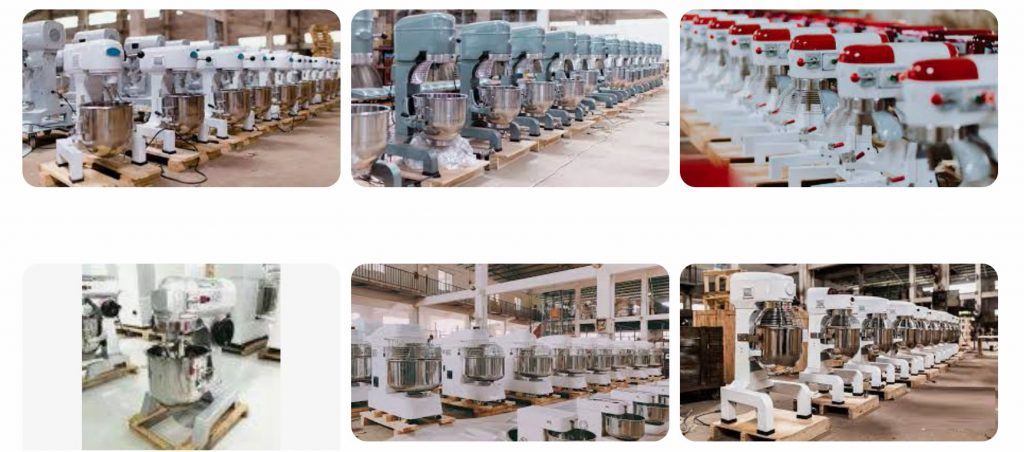

About LKMixer

LKMixer is a professional manufacturer for fertilizer production line, grinder, mixer and granulator, shredder. These machines are widely used in food, pharmaceutical, cosmetic, health care products and chemical industries. The Food materials like Peanut, mushroom, seeds, potato, bean, tobacco, salt, cannabis, tea, Sugar, corn, Coffee, rice, pepper, grain as so on. Grinders have many types such as Pulse Dust Grinder which suitable for zero pollution environment, Turbine Mill which is suitable for coffee bean, 12-120mesh all can meet, Ultrafine Grinding Mill covers 80-200mesh, and also Winnowing Dust Grinder or other grinding machines like SF Hammer. Welcome to contact us for details. Contact us for more information. Proposal, catalog, quotation. Mobile/WhatsApp: +86 18019763531 Tel: +86 21 66037855 Email: sales@lkmixer.com