Grinding Machine Philippines

WFGrinding Machine shipped to Philippines by 2020Y. Feb. LINKER Grinding Machine and Blending machine are well sell in Philippines as its good effect of blending and grinding. High effectiveness, no dead ends, mix evenly. And they are most commonly used for intimate dry mixing of free flowing solids.

Grinding Machine for Sale in Philippines

Top Wheat Grinder Mill for Sale & Price:

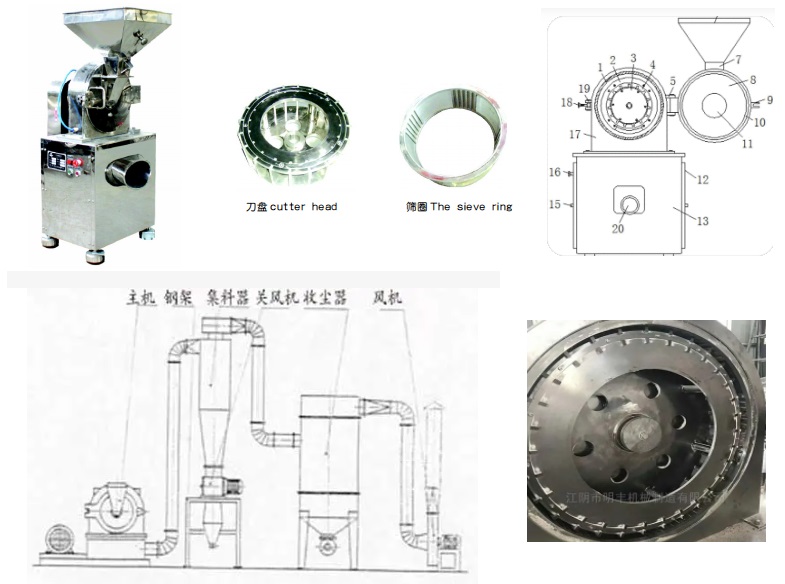

WFJ Turbo Grinder

WF Universal Grinder – Hammer Mill

- Feeding Granularity: 10~15mm;

- Powder Size: 20-150mesh

- Capacity: 60-2000kg/h

- Motor Power (KW): 4-30kw;

- Axis Rotating Speed(r/min):2200~5300;

- Dimension(mm):500*500*1200~1800*1200*2500.

- Price: $ 50-1,179. Video

- Application: metal, Medicine, metal, potato, mushroom, bean, seeds, rice, tea, herb, pepper, grain, food, corn, Sugar, spice,

WF Dust Collector Grinder

- Feeding Granularity: <10mm~<20mm;

- Powder Size: 12~120 mesh;

- Capacity:100~2000kg/h(according different modes and raw materials);

- Motor Power (KW): 11.25~64.25kw;

- Axis Rotating Speed(r/min):1400~3800;

- Price: $ 50-1,179. Video

- Application: Medicine, potato, bean, rice, herb, pepper, corn, grain, food, corn, Sugar

About LKMixer

LKMixer is a professional manufacturer for fertilizer production line, grinder, mixer and granulator, shredder. These machines are widely used in food, pharmaceutical, cosmetic, health care products and chemical industries. The Food materials like Peanut, mushroom, seeds, potato, bean, tobacco, salt, cannabis, tea, Sugar, corn, Coffee, rice, pepper, grain as so on. Grinders have many types such as Pulse Dust Grinder which suitable for zero pollution environment, Turbine Mill which is suitable for coffee bean, 12-120mesh all can meet, Ultrafine Grinding Mill covers 80-200mesh, and also Winnowing Dust Grinder or other grinding machines like SF Hammer. Welcome to contact us for details. Contact us for more information. Proposal, catalog, quotation. Mobile/WhatsApp: +86 18019763531 Tel: +86 21 66037855 Email: sales@lkmixer.com

Contact Us

Grinding Machine Philippines Video

FAQ(Click and See More)

Are you manufacturer?

Yes, our factory produced grinder, mixer, pulverizer for over 20 years.

How to choose the suitable mode?

1. Please provide to us the product material you are use the machine to grinding for.

2. The capacity you request.

3. Consider the layout of your factory, the height width and length of the machine location.

4. If your product material is not normal type, we can arrange trail to estimate the capacity of output.

5. Our sales will recommend the right mode to you.

Is the machine able to have water cooling system?

Yes, water cooling system can customize according to customer request. Many of the machine we producing is with water cooling system.

Do you produce large machine?

Yes, large machine is the major products we are producing. These machine exported to over 30 countries and regions, customer feedback quite good.

Why sometimes larger grinder noise is smaller than the small mode grinder?

Because the medium or small size running speed is faster than larger machine. The noise is decided by the running speed. Also, if there is hole open on the machine, the noise will also larger.

The water cooling system on the grinders do they work?

If we add the water to the water jacket is it air tight?

It is totally ok to use. No leakage.

What is the thickest screen you can provide us?

We can provide 0.5mm, 1mm thickness screens.

Material type of screen: SUS304 stainless steel.

You can choose another type of screen, also stainless steel, like the follow video shows, the screen have 2 layers, one layer large hole, another layer 40mesh as you request. This two layers are welded together. this kind of screen is more cheap to save the cost.

Do you have certification for motors?

Yes, we have CCC, GB, EN, IEC, UL certification for motors.

All of the new grinders need emergency shut off. So if the door on the grinder is open the machine will not start.

ok, it is no problem, we can add emergency shut off, if the main grinder door open, the machine can not start, and if the machine in running and the main grinder door open, the machine will stop, but the running of the machine can not stop immediately because of the iterance. The rotating of the spindle will stop slowly after the machine shut down because of inertia, so it is still dangerous to open the door in running of machine.

Why Choose Us?

We have 20 years manufacturing experiences; 15600 cubic meters factory area; 5000sets annual capacity; 55 professional engineers;

Can you support OEM?

– Yes, OEM or ODM. Machine can be customized according to customer detail requirement, including capacity and voltages, motor certifications.

– Drawing and raw materials also can be customized.

What are our main products?

Our products includs powder grinding mills, classifiers, coating machines, mixing machines, etc.

What after-sale services?

– 7*24 customer service online;

– 7*24 engineers online services;

– 12 months warranty services.

How long time is our production time?

Normally 60 to 90 days after receive the deposit payment.

What services do you provide?

– We offer full services covers whole process of your new project. Including your factory feasibility assessment, process flow chart, preliminary factory machines layout and factory building planning, project budget estimation, project time schedule arrangements, etc.

– We supply sample processing tests as to your detail product. To estimate the capacity of machine, this helps you controls better to the capacity and get to know more accuracy of quantity of machine you need to book. In our test station where are equipped with our various machine products,this is also help you compare performances of different types of machines or process.

– For large machine. If neccessary, we can assign engineers to the your project site and offer on-site technical instruction and supervision during the machine installation, commissioning and test run.

Warranty Period?

– Warranty period is 12 months after installation.

– We offer lifetime service for our machine products after the delivery, and will follow up the machine status with our clients after the successful machine installation in our clients’ factories.

For details, please contact our project consultants, thank you.

What payment terms do we offer?

– 50% by T/T deposit payment.

– 50% balance by T/T before shipment.

Packing method and shipment ways?

– For machines, we ship with export wooden box and pallet suitable for long time boat transportation in standard containers or Bulk by sea.

– For spare parts, wooden Case and pallet for delivery by air.

How to choose the right models?

– Choose small or large ? Calculate your current customer capacity request, this is to get a estimate capacity needs. To think about you only for small quantity use or large quantity. Do you want to expand your customer base so that need to expand your capacity in near future? If yes, you can order larger machine instead of small machine. If not, smaller one is more suitable for you.

– Choose single or whole group? Single machine is cheaper and easy to move from here to there, space location are also easy. Whole group machine including material feeder, main machine, cyclone sperator and rotary valve. Whole group machine not easy to move cause of link of each portions. But whole group also advantages such as easy to dust collect, save manpower. Think about clearly what you want, we would know which is right to choose.

– If you think about your customers and volume, you’ll be off to a good start in knowing what you need from your grinder.

How to calculate the Quantity of machine that I need?

If you are a large factory request several machine. You may think the question of quantity that you need to purchase. This question actually we have already talked when we previously discussed how much the grinder can produce in an hour.

Based on the capacity of how much kg/hour that we can get, it’s very each to calculate the quantity of machine that you may need finally.

One of the questions that may pay attention here is, how many hour you plan to work per day? If you plan to work 24 hours non-stop, you need to have cooling water system definitely to cool down the machine. And the working hour also need to be calculated into your capacity calculation.

Automatically material feeder helps to feed the raw material automatically, so that no need to stop and refill the hopper frequently. Cyclone Seperator helps output material quickly, vibrating table screener helps screen out the qualified fineness material. All these portion run automatically will significantly help improve the efficiency and capacity.

A good rule of thumb to remember is that a larger capacity usually also means a higher level of speed.

How to design my factory layout?

Right size is definitely important for grinder business.

If your business is small, you may not have the space to accommodate a large grinder. Read keep in mind, While, that a smaller grinder doesn’t have to mean that it’s not able output as much as a bigger one.

On the contrary, if you have a lot of space, you may require different things from your grinder.

For example, you may want to have dust collector and material feeder for your environment production and operation convenience.

Do you inspect the finished products?

Yes. 100% of inspection for each step of products will be carried out by QC department until shipping.

What detail information do you want to know if we want to get a quotation?

a). The size of your products before grinding and after grinding, by mesh or mm or um.

b). The application for your products. This machine is used for food or chemical or pharmaceutical? The more detail the better.

c). If any special packing methods that you need.

d). Raw material is 304 or 316 that you request.

e). The motor if need any certification or not.

f). If need to customize voltage or not, how much voltage, 380V 440V? or any.