Industrial Bean Grinder

Industrial Large Bean Grinder:

I. Introduction

Brief explanation of what a bean grinder is

An industrial bean grinder is a powerful machine specifically designed for grinding beans, such as coffee beans, into fine particles. It is commonly used in industries and large-scale operations where large quantities of beans need to be processed efficiently and consistently. The primary purpose of an industrial bean grinder is to break down the beans into a desired particle size, which is crucial for various applications, especially in the food and beverage industry.

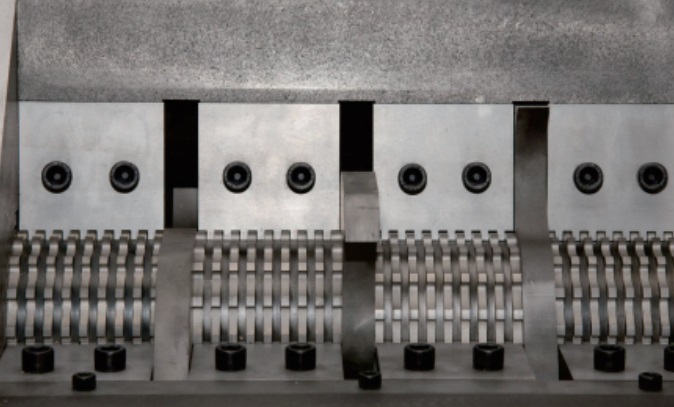

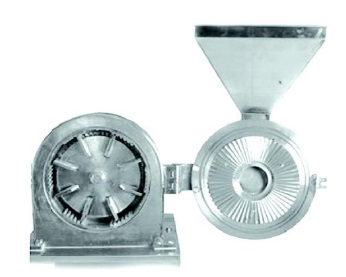

At its core, an industrial bean grinder consists of a motor, a grinding chamber, and a set of burrs or blades. The motor provides the necessary power to rotate the burrs or blades at high speeds, creating the grinding action. The grinding chamber, often made of durable materials like stainless steel, houses the beans and contains the rotating burrs or blades. These burrs or blades are strategically positioned to ensure thorough and uniform grinding of the beans.

The process of grinding beans in an industrial grinder begins with loading the beans into the hopper, which is a container located on top of the grinder. The beans then pass through a series of mechanisms that regulate their flow into the grinding chamber. Once inside, the beans come into contact with the rotating burrs or blades, which rapidly pulverize them into smaller particles. The resulting ground beans, also known as coffee grounds, exit the grinder through a chute or spout and can be collected in a container or conveyed to the next stage of the production process.

One of the key features of an industrial bean grinder is its ability to control the particle size of the ground beans. This is achieved by adjusting the distance between the burrs or blades, which determines the fineness or coarseness of the grind. The particle size is crucial because it directly affects the extraction process when brewing coffee or preparing other bean-based products. Different brewing methods, such as espresso, drip coffee, or French press, require specific grind sizes to achieve the desired flavor and aroma.

In addition to controlling particle size, industrial bean grinders often offer other customizable settings to meet specific production needs. These may include adjustable grinding speed, automated dosing for precise portioning, and programmable settings for different bean types or blends. Some advanced models may even feature built-in sensors or monitoring systems to ensure consistency in grind quality and prevent overheating or clogging.

Industrial bean grinders are widely used in the food and beverage industry, including coffee shops, roasteries, and large-scale production facilities. They play a vital role in ensuring the quality and consistency of the final product. By precisely grinding beans to the desired particle size, industrial grinders contribute to enhancing flavor extraction, aroma release, and overall beverage quality. They also help maximize efficiency by reducing processing time and labor requirements compared to manual or smaller-scale grinding methods.

Overall, an industrial bean grinder is a robust and efficient machine designed for heavy-duty bean grinding applications. With its ability to control particle size and various customizable settings, it enables businesses to produce consistent, high-quality coffee grounds or other bean-based products on a large scale. Whether it’s a busy coffee shop serving freshly brewed cups of coffee or a production facility producing packaged ground coffee for distribution, an industrial bean grinder is a critical component in achieving excellence in taste and meeting the demands of consumers.

II. Literature Review

Historical overview of bean grinders

Bean grinders have a long and fascinating history that dates back centuries. Throughout different civilizations and eras, humans have sought ways to harness the flavors and aromas locked within coffee beans and other types of beans. The evolution of bean grinders reflects our quest for the perfect cup of coffee and the advancement of technology over time.

The story of bean grinders begins in the ancient world. As early as the 9th century, coffee beans were being cultivated and enjoyed in the Arab world. The earliest grinding method involved pounding the beans with a mortar and pestle to achieve a coarse grind. This method was labor-intensive and time-consuming, but it allowed people to release the flavors and aromas of the beans.

As coffee spread to different regions, new grinding techniques emerged. In the 14th century, Persians introduced a more sophisticated grinder known as the “bowl mill.” This grinder consisted of a bowl-shaped vessel with a handle and a stationary stone grinder inside. By rotating the handle, the beans were crushed between the stone and the bowl, resulting in a finer grind compared to the mortar and pestle method.

The 17th century brought further advancements in bean grinding technology. In Europe, coffee houses became popular gathering places, and demand for freshly ground coffee grew. Inventors began designing mechanical devices to streamline the grinding process. One notable invention was the manual grinder, also known as a “hand mill” or “box mill.” This device featured a crank handle that rotated a set of grinding burrs, allowing for a more efficient and consistent grind.

The Industrial Revolution of the 18th and 19th centuries revolutionized many aspects of daily life, including bean grinding. The invention of steam power and the development of mechanical engineering led to the creation of steam-powered bean grinders. These early industrial grinders used steam engines to drive the grinding mechanism, significantly increasing grinding capacity and reducing the reliance on manual labor.

With the advent of electricity in the late 19th century, electric bean grinders emerged. These grinders featured electric motors that replaced steam power, making them more convenient and accessible to the masses. Electric grinders quickly gained popularity and became a common household appliance. They offered adjustable settings for grind size, allowing users to customize their coffee experience.

In the 20th century, advancements in materials and technology led to the development of more efficient and versatile bean grinders. Steel burrs replaced stone grinders, providing better durability and precision in grinding. Electric grinders became more compact, affordable, and user-friendly, enabling people to enjoy freshly ground coffee in the comfort of their homes.

In recent decades, the demand for specialty coffee and the rise of coffee culture have driven further innovation in bean grinding. High-end coffee shops and professional baristas started using advanced grinders that featured precise grind size adjustments and programmable settings for different brewing methods. These grinders ensure consistency and quality in the coffee extraction process, resulting in superior flavors and aromas.

Today, bean grinders come in various forms, from manual hand grinders to semi-automatic and fully automatic electric grinders. The market offers a wide range of options to cater to different preferences and needs. Modern bean grinders often incorporate advanced technologies like digital displays, timers, and built-in scales for accurate measurements. Some even connect to smartphone apps for enhanced control and customization.

The historical journey of bean grinders showcases our ongoing pursuit of the perfect cup of coffee. From ancient pounding methods to the cutting-edge technology of today, bean grinders have evolved to meet the demands of coffee lovers worldwide. These machines continue to play a vital role in unlocking the rich flavors and aromas hidden within coffee beans, enabling us to savor every sip of this beloved beverage.

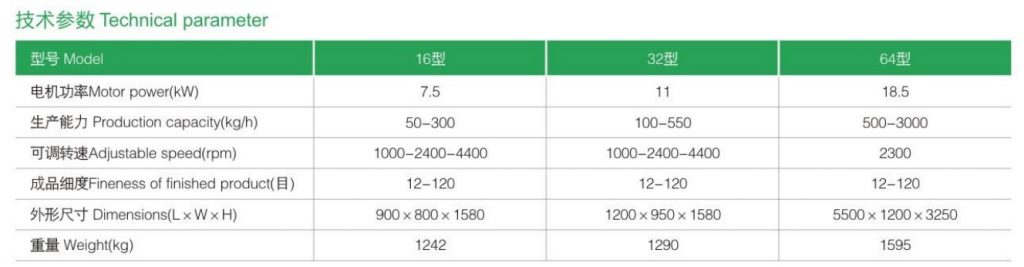

Parameter of Industrial Dust Grinder:

| Model | GFSJ16GFSJGFSJ-G |

| Motor Power(KW) | 7.5 |

| Production Capacity(KG/H) | 50-300 |

| Adjustable Speed(RPM) | 1000-2400-4400 |

| Fineness of Finished Product(Mesh) | 12-120 |

| Dimension(L*W*H)(mm) | 900*800*1580 |

| Weight(KG) | 1242 |

| Model | GFSJ32 |

| Motor Power(KW) | 11 |

| Production Capacity(KG/H) | 100-550 |

| Adjustable Speed(RPM) | 1000-2400-4400 |

| Fineness of Finished Product(Mesh) | 12-120 |

| Dimension(L*W*H)(mm) | 1200*950*1580 |

| Weight(KG) | 1290 |

| Model | GFSJ64 |

| Motor Power(KW) | 18.5 |

| Production Capacity(KG/H) | 500-3000 |

| Adjustable Speed(RPM) | 2300 |

| Fineness of Finished Product(Mesh) | 12-120 |

| Dimension(L*W*H)(mm) | 5500*1200*3250 |

| Weight(KG) | 1595 |

| Business Type: | Manufacturer/Factory | Main Products: | Mill, grinder, granulator, mixer, Crushing Equipment |

| Number of Employees: | 100 | Year of Establishment: | 2014.05 |

| Production Capacity | 5000Set/Year | After-sales Service: | Technical Support; on-line teach lessons |

| R&D Capacity: | ODM, OEM | Annual Output Value: | US$5 Million – US$10 Million |

| No. of R&D Staff: | 5 | No. of Production Lines: | 6 |

LK Mixer is a professional manufacturer for grinder, mixer and pulverizer. These machines are widely used in pharmaceutical, cosmetic, health care products and chemical industries. Our main product including granulating machine, grinder, mixer, dryer, etc. All mechanical products in accordance with the China GMP design requirements. And also we have other certifications such as CE, UL for motors.

Business Philosophy

“Quality is the main policy of sales” and “integrity is the principle of success” are the business philosophy of our people. We carry out one-year warranty, lifelong maintenance service, with technical consultation, with material test machine and other services, and long-term supply of equipment. Welcome new and old customers to negotiate cooperation!

Certifications:

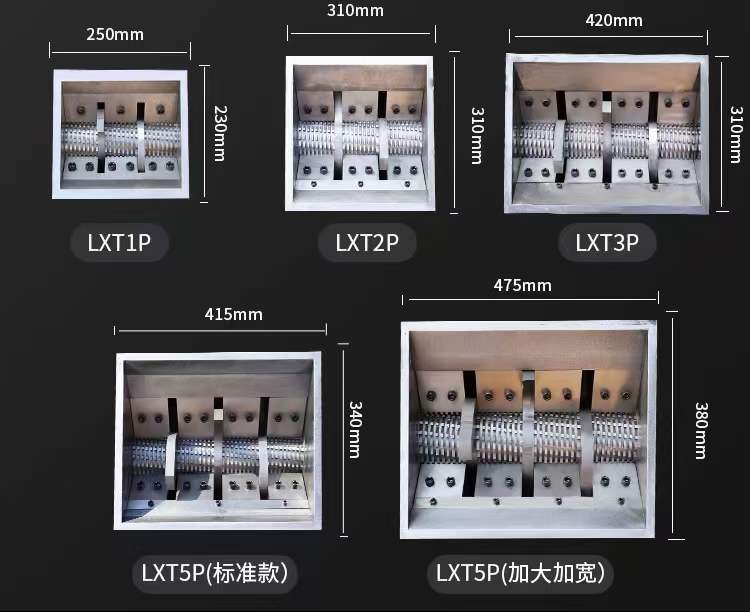

Cutting Knife Type Pictures:

Electric Cabinet with UL Certification

Cyclone Processor and Motors:

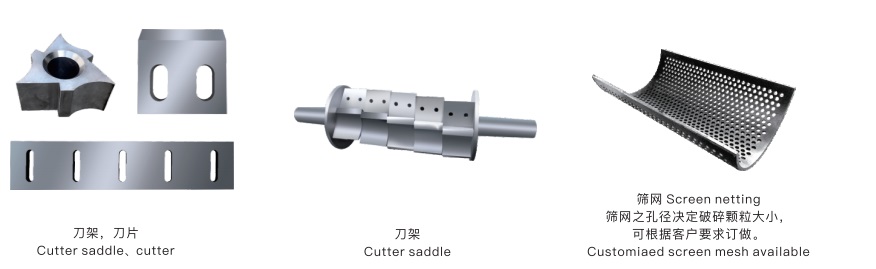

Spare Parts:

Small Machine Packing:

Small machine packed with export fumigation-free wooden cases, goes with bulk shipment or in container.

When packing small machines for sea shipment, it is important to take measures to ensure that the machines are protected from damage during transit. Here are some general steps that a manufacturer may follow when packing small machines for sea shipment:

- Clean and dry the machine: Before packing, the machine should be thoroughly cleaned and dried to prevent any moisture or debris from causing damage during transit.

- Disassemble the machine: If possible, the machine should be disassembled into its component parts to reduce its overall size and make it easier to pack.

- Wrap the machine in protective material: The machine should be wrapped in a layer of protective material, such as bubble wrap or foam, to protect it from scratches and impact during transit.

- Place the machine in a sturdy box: The wrapped machine should then be placed in a sturdy box that is appropriate for the size and weight of the machine. The box should be made of durable material, such as corrugated cardboard or plywood, and should be able to withstand the rigors of sea transit.

- Add packing material: The box should be filled with packing material, such as packing peanuts or air pillows, to provide cushioning and prevent the machine from shifting during transit.

- Seal the box: The box should be securely sealed with high-quality packing tape to prevent it from opening during transit.

- Label the box: The box should be clearly labeled with the machine’s name, weight, and any other relevant information, as well as the destination address and contact information.

Overall, the goal is to pack the small machine in a way that will protect it from damage during transit and ensure that it arrives at its destination in good condition. It is important to follow proper packing procedures and use high-quality packing materials to minimize the risk of damage during sea shipment.

Large Machine Packing:

Packing a large machine for sea shipment can be a complex and challenging task. However, with careful planning and attention to detail, it is possible to pack a large machine for sea shipment in a way that will ensure that it arrives at its destination in good condition. Here are some general steps that a manufacturer may follow when packing up a large machine for sea shipment:

- Clean and prepare the machine: Before packing, the machine should be thoroughly cleaned and prepared. All fluids, such as oil or coolant, should be drained, and any loose or detachable parts should be removed.

- Disassemble the machine: If possible, the machine should be disassembled into its component parts to reduce its overall size and make it easier to pack. Each part should be carefully labeled and numbered to ensure that it can be easily reassembled at the destination.

- Protect delicate parts: Delicate or fragile parts should be wrapped in protective material, such as bubble wrap or foam, to protect them from damage during transit.

- Build a custom crate: A custom crate should be built around the machine to provide a secure and sturdy enclosure. The crate should be made of durable material, such as plywood, and should be designed to fit the machine snugly. The crate should also include braces or supports to prevent the machine from shifting during transit.

- Add cushioning material: The crate should be filled with cushioning material, such as packing peanuts or air pillows, to provide extra protection and prevent the machine from moving or shifting during transit.

- Securely fasten the machine: The machine should be securely fastened to the crate to prevent it from moving or shifting during transit. This may involve using straps, bolts, or other fasteners to hold the machine in place.

- Seal and label the crate: The crate should be securely sealed with high-quality packing tape, and should be clearly labeled with the machine’s name, weight, and any other relevant information. The destination address and contact information should also be clearly marked on the crate.

Overall, packing a large machine for sea shipment requires careful planning and attention to detail. It is important to use high-quality materials and follow proper packing procedures to ensure that the machine arrives at its destination in good condition. A professional packing and shipping company may be consulted to ensure that the machine is properly packed and prepared for sea shipment.

Customer Side Machine Groups Showcase Videos:

Dust Collector Shipment

Shipment – Packing Method

Two Large Industrial Grinder Ready to Ship

Domestic Shipment Show Case:

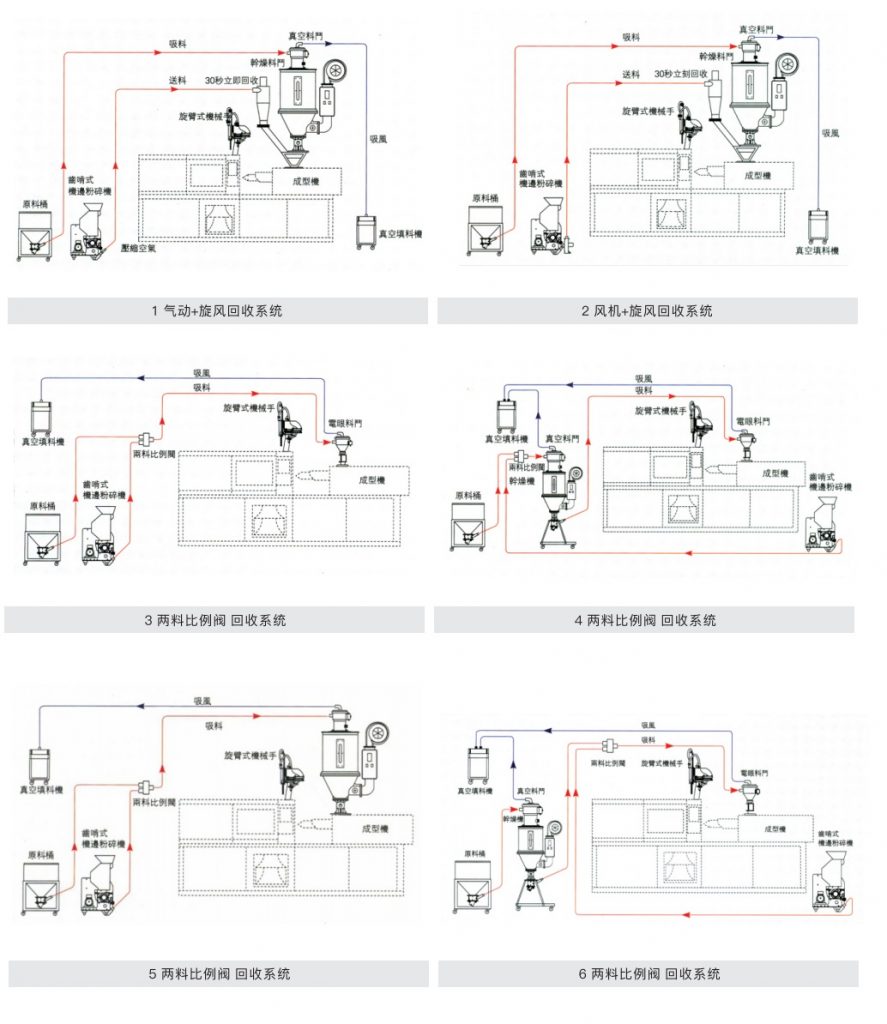

Installation Layout:

Maintenance and Safety Measures

Proper maintenance practices for the machine

Proper maintenance practices are essential for ensuring the efficient and safe operation of a universal grinder. Here are some maintenance practices that should be followed:

- Regular cleaning – The machine should be cleaned regularly to remove any debris, dust, or coolant that may accumulate on the machine’s surfaces. This can be done using a soft brush, air hose, or a cleaning solution.

- Lubrication – The machine’s moving parts should be lubricated regularly to reduce friction and wear. The manufacturer’s recommendations for lubrication intervals and types should be followed.

- Inspection – The machine should be inspected regularly for any signs of wear, damage, or misalignment. Any issues should be addressed immediately to prevent further damage or safety hazards.

- Replacement of worn or damaged parts – Worn or damaged parts should be replaced immediately with genuine parts from the manufacturer.

- Calibration – The machine should be calibrated regularly to ensure that it is operating within the specified tolerances and accuracy.

- Operator training – Proper operator training is essential for ensuring the safe and efficient operation of the machine. Operators should be trained on the proper operation, maintenance, and safety procedures for the machine.

- Record keeping – A maintenance log should be kept to track the machine’s maintenance history, including cleaning, lubrication, inspection, and repairs. This can help identify any trends or issues that need to be addressed.

Following these maintenance practices can help ensure the safe and efficient operation of a universal grinder, prolong its lifespan, and reduce the risk of downtime and costly repairs.

Safety measures for operators and workers

Safety measures for operators and workers are crucial when using a universal grinder. Here are some safety measures that should be followed:

- Personal protective equipment (PPE) – Operators and workers should wear appropriate PPE, including safety glasses, hearing protection, gloves, and safety shoes.

- Machine guards – The machine should be equipped with proper machine guards to prevent access to the grinding wheel during operation. The guards should be in good condition and properly installed.

- Lockout/tagout procedures – Lockout/tagout procedures should be followed to ensure that the machine is not accidentally started or energized during maintenance or repair.

- Training – Operators and workers should receive proper training on the safe operation of the machine, including the use of PPE, machine guards, and lockout/tagout procedures.

- Inspection – The machine should be inspected regularly for any signs of wear, damage, or misalignment that may pose a safety hazard.

- Proper use of grinding wheels – Operators should ensure that the grinding wheel is properly installed, dressed, and aligned. The grinding wheel should not be overloaded or forced into the material being ground.

- Proper handling of coolant – If coolant is used, operators should ensure that it is properly mixed, applied, and contained. Coolant should not be allowed to accumulate on the floor, as it can create a slipping hazard.

- Emergency procedures – Emergency procedures should be established and communicated to all operators and workers in case of an accident or injury.

Following these safety measures can help prevent accidents and injuries when using a universal grinder. It is important to prioritize safety and ensure that all operators and workers are trained and informed about the potential hazards of the machine.

About LKMixer

LKMixer is a professional manufacturer for fertilizer production line, grinder, mixer and granulator, shredder. These machines are widely used in food, pharmaceutical, cosmetic, health care products and chemical industries. The Food materials like Peanut, mushroom, seeds, potato, bean, tobacco, salt, cannabis, tea, Sugar, corn, Coffee, rice, pepper, grain as so on. Grinders have many types such as Pulse Dust Grinder which suitable for zero pollution environment, Turbine Mill which is suitable for coffee bean, 12-120mesh all can meet, Ultrafine Grinding Mill covers 80-200mesh, and also Winnowing Dust Grinder or other grinding machines like SF Hammer. Welcome to contact us for details. Contact us for more information. Proposal, catalog, quotation. Mobile/WhatsApp: +86 18019763531 Tel: +86 21 66037855 Email: sales@lkmixer.com

Contact Us

Bean Grinder Youtube Video (See More)

FAQ(Click and See More)

What is the best way to grind beans?

When it comes to grinding beans, the best method depends on your personal preferences and the brewing method you intend to use. Different grind sizes yield different flavors and extraction levels, so finding the right grind size for your preferred brewing method is essential. Here, we’ll explore some common brewing methods and the corresponding grind sizes that generally work well.

Drip Coffee Maker: Drip coffee makers are a popular choice for many households. For this method, a medium grind is usually recommended. The coffee grounds should be similar in texture to granulated sugar. This grind size allows water to flow through the grounds at a steady rate, resulting in a well-balanced cup of coffee.

French Press: French press brewing involves steeping coffee grounds in water and then pressing the plunger to separate the grounds from the liquid. For a French press, a coarse grind is ideal. The coarseness allows for a slower extraction, resulting in a rich and full-bodied cup of coffee. The grounds should resemble coarse sea salt to prevent sediment from seeping through the plunger.

Espresso Machine: Espresso machines require a fine grind to maximize extraction in a short amount of time. The grounds should have a consistency similar to table salt. The fine grind allows for a higher surface area, facilitating the rapid extraction of flavors and the formation of a rich, concentrated shot of espresso.

Pour-Over: Pour-over brewing involves manually pouring hot water over coffee grounds in a filter. This method offers a lot of control over the brewing process. A medium-fine grind is generally recommended for pour-over methods like V60 or Chemex. The grounds should be slightly finer than granulated sugar. This grind size promotes a balanced extraction, allowing for a clean and flavorful cup of coffee.

Aeropress: The Aeropress is a versatile brewing method that allows for various grind sizes depending on your desired outcome. For a standard brew, a medium grind is a good starting point, similar to drip coffee. However, the beauty of the Aeropress lies in its flexibility, so you can experiment with different grind sizes to find the flavor profile that suits your taste preferences.

Remember, these recommendations are guidelines, and you can always adjust the grind size to fine-tune your coffee’s flavor. Additionally, it’s essential to grind your beans just before brewing to ensure freshness and optimal flavor extraction. Pre-ground coffee can quickly lose its aroma and flavor.

Investing in a quality burr grinder is also highly recommended. Burr grinders offer more precise and consistent grind sizes compared to blade grinders, resulting in a better extraction and a tastier cup of coffee.

Ultimately, the best way to grind beans is the one that suits your taste buds and brewing method. Experimenting with different grind sizes and techniques will help you discover the perfect balance of flavors, unlocking the full potential of your beans and enhancing your coffee experience.

What is a coffee bean grinder called?

A coffee bean grinder is simply called a “coffee grinder.” This device is specifically designed to grind coffee beans into smaller particles, allowing for the extraction of flavors and aromas when brewing coffee. Coffee grinders come in various forms, from manual hand grinders to electric grinders, and they play a crucial role in achieving a fresh and flavorful cup of coffee.

The term “coffee grinder” is a generic name that encompasses different types and models of grinders available on the market. Let’s explore some of the common types of coffee grinders:

Manual Coffee Grinder: A manual coffee grinder, also known as a hand grinder, requires physical effort to grind the coffee beans. It typically consists of a handle connected to a grinding mechanism, such as burrs or blades. By rotating the handle, the user grinds the beans to the desired consistency. Manual grinders are often compact, portable, and suitable for travelers or those who prefer a more hands-on approach to grinding coffee.

Electric Blade Grinder: An electric blade grinder operates with the help of a motor and features a spinning blade that chops the coffee beans into smaller pieces. Blade grinders are relatively affordable and straightforward to use. However, they tend to produce an inconsistent grind size due to the nature of the chopping action. This can result in uneven extraction and affect the overall flavor of the coffee.

Electric Burr Grinder: Electric burr grinders are considered the gold standard for grinding coffee beans. They use two burrs, either conical or flat, to crush the beans into precise and consistent particle sizes. The burrs can be adjusted to control the grind size, allowing for customization based on brewing preferences. Electric burr grinders are known for producing a more uniform grind, which contributes to better flavor extraction and a higher-quality cup of coffee.

Within the realm of coffee grinders, there are various brands and models that offer different features and capabilities. Some advanced electric burr grinders have built-in scales, timers, and programmable settings for precise and convenient grinding. These features provide greater control over grind size and brewing consistency, ensuring an exceptional coffee experience.

It’s worth noting that coffee grinders are not limited to grinding coffee beans alone. They can also be used to grind other types of beans, such as spices or grains, depending on the specific design and functionality of the grinder.

In summary, a coffee bean grinder is commonly referred to as a “coffee grinder.” This versatile device is available in manual and electric versions, with electric burr grinders being the preferred choice among coffee enthusiasts. By grinding coffee beans to the desired consistency, coffee grinders play a vital role in unlocking the flavors and aromas of the beans, ultimately resulting in a delicious and satisfying cup of coffee.

How do you use a bean grinder?

Using a bean grinder is a straightforward process that can be easily mastered with a few simple steps. Whether you have a manual or electric grinder, the general procedure remains largely the same. Here’s a step-by-step guide on how to use a bean grinder:

Set Up: Begin by setting up your bean grinder in a suitable location. Ensure it is on a stable surface and close to a power source if you have an electric grinder. If you have a manual grinder, place it on a clean and sturdy countertop.

Adjust the Grind Size: Depending on the type of grinder you have, you may have the option to adjust the grind size. Consider the brewing method you’ll be using and refer to the grinder’s manual or instructions to understand how to adjust the grind size. Typically, you can adjust a dial or knob to make the grind coarser or finer. Coarser grinds are suitable for methods like French press, while finer grinds are ideal for espresso machines. Experiment with different settings to find your desired grind size.

Measure the Beans: Measure the desired amount of coffee beans that you want to grind. The ideal ratio is usually one to two tablespoons of coffee beans per six ounces of water, but you can adjust the amount based on your preference for a stronger or milder cup of coffee. Remember that it’s best to grind the beans just before brewing to preserve the freshness and flavors.

Load the Beans: Open the hopper or bean reservoir on top of the grinder and pour in the measured coffee beans. Avoid overloading the grinder to prevent uneven grinding or damage to the machine. If you have a manual grinder, you may need to remove a top compartment or lid to access the grinding chamber.

Start Grinding: Once the beans are loaded, close the hopper or grinding chamber securely. If you have an electric grinder, plug it into a power source. For manual grinders, ensure all components are assembled correctly. Hold the grinder firmly or secure it in place, depending on the design, and initiate the grinding process.

Grind Time: For electric grinders, simply press the power button or switch to start the grinding process. The grinder will automatically grind the beans for the predetermined duration. If you have a manual grinder, use the handle or crank to rotate the grinding mechanism. Continue grinding until you achieve the desired grind size.

Check the Consistency: After grinding, inspect the coffee grounds to ensure they have the desired consistency. Different brewing methods require specific grind sizes, so check for uniformity. Adjust the grinder settings and repeat the grinding process if necessary.

Collect the Grounds: Open the grinder’s chute, spout, or container to access the ground coffee. Most grinders have a built-in receptacle, while others may require attaching a separate container. Carefully collect the freshly ground coffee, making sure none is wasted or spilled.

Brew and Enjoy: With your coffee beans ground to perfection, it’s time to brew and savor your cup of coffee. Choose your preferred brewing method, such as a coffee maker, French press, or espresso machine, and follow the instructions for that specific brewing technique.

Clean and Maintain: After using the grinder, clean it thoroughly according to the manufacturer’s instructions. Empty any remaining coffee grounds, wipe the surfaces, and remove any residue or oils that may have accumulated. Regular maintenance will ensure the longevity and performance of your bean grinder.

By following these steps, you’ll be able to use a bean grinder confidently and consistently produce freshly ground coffee for a delightful and flavorful coffee experience.

What does a coffee bean grinder do?

A coffee bean grinder is a device specifically designed to break down coffee beans into smaller particles. Its primary function is to grind coffee beans to a desired consistency, allowing for the extraction of flavors and aromas when brewing coffee. In essence, a coffee bean grinder transforms whole beans into coffee grounds, which are then used to create a flavorful and enjoyable cup of coffee.

The process of grinding coffee beans is essential because it maximizes the surface area of the beans that comes into contact with water during brewing. This increased surface area allows for a more efficient extraction of the desirable compounds found within the beans, such as oils, flavors, and aromas. Without grinding, the water would only interact with the outer layer of the bean, resulting in a weak and underwhelming cup of coffee.

A coffee bean grinder achieves this by breaking down the beans into smaller particles, thereby exposing a larger surface area. The grinder uses either blades or burrs to accomplish this task. Blade grinders have a spinning blade that chops the beans, while burr grinders have two abrasive surfaces (either conical or flat) that crush the beans between them.

The grind size produced by a coffee bean grinder plays a crucial role in the brewing process. Different brewing methods require specific grind sizes to achieve the desired flavor profile. For instance, a coarse grind is typically used for methods like French press, while a fine grind is preferred for espresso machines. The grind size directly affects the rate of extraction, with finer grounds extracting more quickly than coarser ones.

The ability to adjust the grind size is one of the key features of a coffee bean grinder. By offering different settings or adjustments, the grinder allows users to customize the grind size based on their preferred brewing method. This flexibility empowers coffee enthusiasts to experiment and find the optimal grind size that suits their taste preferences and brewing equipment.

Freshness is another critical aspect of coffee, and grinding beans just before brewing is a crucial step in preserving that freshness. Coffee beans contain volatile compounds that contribute to the aroma and flavor. When the beans are ground, these compounds are released into the air, gradually diminishing the overall freshness of the coffee. By grinding beans on-demand, a coffee bean grinder ensures that the maximum amount of flavor and aroma is retained in the coffee grounds, resulting in a more flavorful and satisfying cup of coffee.

Moreover, owning a coffee bean grinder provides the opportunity to explore a wide range of coffee beans from different origins and roasts. Pre-ground coffee often lacks the complexity and freshness found in freshly ground beans. By grinding beans at home, coffee enthusiasts can experience the nuanced flavors and aromas of various coffees and have greater control over their coffee brewing process.

In summary, a coffee bean grinder is a device that grinds coffee beans to a specific consistency to enhance the flavor and aroma extraction during brewing. It allows users to customize the grind size based on their preferred brewing method, contributing to a more enjoyable and personalized coffee experience. By grinding beans just before brewing, a coffee bean grinder ensures the maximum freshness and flavor retention, unlocking the full potential of the coffee beans and resulting in a delicious cup of coffee.