Industrial Cannabis Grinder

Industrial cannabis grinders are specifically designed to process large quantities of cannabis or hemp quickly and efficiently. These grinders are typically used in the cannabis and hemp processing industry, where they are used to grind up raw plant material for further processing or extraction.

Industrial cannabis grinders can come in different sizes and types, including horizontal and vertical grinders. They are usually powered by electricity and may have various features such as different blade types, variable speed settings, and automatic feeding mechanisms.

Some industrial cannabis grinders can process hundreds of pounds of plant material per hour, making them ideal for large-scale production. They are also designed to produce a consistent grind size, ensuring that the processed material is uniform and suitable for further processing or extraction.

Overall, industrial cannabis grinders play an important role in the cannabis and hemp processing industry, allowing for the efficient and consistent processing of large quantities of plant material.

Super Grinder

- Feeding Granularity: <10mm;

- Powder Size: 80-320mesh

- Capacity: 10~2000kg/h according to different material

- Motor Power (KW): 13.37~119kw;

- Axis Rotating Speed(r/min):2000~6200;

- Dimension(mm):4200*1250*2700~8500*2800*4830.

- FOB Unit Price: 1 unit $ 12,000-48,923. More than 5 units: $10,800~44,031 Video

WF Universal Grinder – Hammer Mill

- Feeding Granularity: 10~15mm;

- Powder Size: 20-150mesh

- Capacity: 60-2000kg/h

- Motor Power (KW): 4-30kw;

- Axis Rotating Speed(r/min):2200~5300;

- Dimension(mm):500*500*1200~1800*1200*2500.

- FOB Unit Price: 1 unit $ 2,862~17,538. More than 5 units: $2,585~1,5785 Video

- Application: metal, Medicine, potato, bean, rice, herb, pepper, grain, food, corn, Sugar

WF Dust Collector Grinder

- Feeding Granularity: <10mm~<20mm;

- Powder Size: 12~120 mesh;

- Capacity:100~2000kg/h(according different modes and raw materials);

- Motor Power (KW): 11.25~64.25kw;

- Axis Rotating Speed(r/min):1400~3800;

- FOB Unit Price: 1 unit $ 12,000-64,615. More than 5 units: $10,800~58,154. Video

- Application: Medicine, potato, bean, rice, herb, pepper, grain, food, corn, Sugar

WF Impuse Dust Grinder

- Powder Size: 12~200 mesh;

- Capacity: 10~1500kg/h(according to different mode and raw materials);

- Motor Power (KW): 5.5~22kw;

- Axis Rotating Speed(r/min):2200~5000;

- FOB Unit Price: 1 unit $ 6,462~8,492. More than 5 units: $5,815~7,643. Video

- Application: Medicine, potato, bean, rice, herb, pepper, grain, food, corn, Sugar

GFSJ High Speed Grinder

- Feeding Granularity: <10mm, <15mm;

- Powder Size: 5~80mm;

- Capacity: 10~600kg/h;

- Motor Power (KW): 3~18.5kw;

- Dimension(mm):1050*600*1600~1380*1200*1750.

- FOB Unit Price: 1 whole set unit $ 12,000~41,538. More than 5 whole set units: $10,800~37,385. Video

- Application: Medicine, potato, bean, tea, rice, herb, pepper, grain, food, corn, Sugar

SG Double Shaft Grinder

- Feeding granule size: <5mm;

- Powder Size: 20~40 mesh;

- Capacity: 1~4000kg/h(according to different modes and raw materials);

- Motor Power (KW): 11~15kw;

- FOB Unit Price: 1 unit $ 6,646~10,154. More than 5 units: $5,982~9,138. Video

- Application: Medicine, potato, bean, rice, herb, pepper, grain, food, corn, Sugar

CSJ Coarse Crusher

WFJ Medicine Grinder – Hammer Mill

SF Hammer Mill

WFJ Turbo Grinder

- Feeding Size: 6~15mm;

- Crushing Fineness: 60-150mm;

- Motor Power (KW): 5.5~37kw;

- Axis Rotating Speed(r/min):2200~5500;

- Dimension(mm):550*600*1250~1250*1100*2280.

- FOB Unit Price: 1 whole set including dust collector unit $ 12,000~52,615. More than 5 whole set units: $10,800~47,354. Video

- Application: Medicine, potato, bean, rice, herb, pepper, grain, food, corn, Sugar

B Vacuum Mill

- Feeding Granularity: 10~15mm;

- Powder Size: 20~150 mesh;

- Capacity: 60-2000kg/h (according to mode and different raw material);

- Motor Power (KW): 4~30kw;

- Axis Rotating Speed(r/min):2200~5300;

- Dimension(mm):550*500*1200~1800*1200*2500.

- FOB Unit Price: 1 unit $ 3,692~5,538. More than 5 units: $3,323~4,985. Video

- Application: Medicine, potato, bean, rice, herb, pepper, grain, food, corn, Sugar

FL Airflow Pulverizer Supplier

- Feeding Granularity: <5mm, <10mm;

- Powder Size: 30~120 mesh;

- Capacity: 30~2200kg/h (according to mode and different raw material);

- Motor Power (KW): 4~22kw;

- Axis Rotating Speed(r/min):2200~4200;

- Dimension(mm):550*420*1400~1250*1100*2500.

- FOB Unit Price: 1 unit $ 3,415~4,800. More than 5 units: $3,065~4,320. Video

- Application: Medicine, potato, bean, rice, herb, pepper, grain, food, corn, Sugar

Extra fine cannabis grinder

What is Cannabis Grinder?

A cannabis grinder is a tool used to break up dry cannabis flowers into smaller, more manageable pieces. Grinders are designed to make the grinding process more efficient and to produce a consistent grind size, which can improve the quality of the cannabis material being used. Grinders are commonly used by cannabis enthusiasts, patients, and industry professionals alike, and come in various types, sizes, and materials. Some grinders have multiple compartments that allow for the collection and storage of kief or pollen, while others are designed to be more portable and discreet. Overall, cannabis grinders are an essential tool for anyone who wants to enhance their cannabis experience and get the most out of their cannabis flowers.

Feature:

- Material: Cannabis grinders can be made of various materials including metal, wood, acrylic, and plastic.

- Size: Grinders can come in different sizes and shapes, ranging from small, pocket-sized grinders to large industrial grinders for processing large quantities of cannabis.

- Number of compartments: Some grinders have multiple compartments, including a chamber for grinding the cannabis, and other chambers for collecting and storing kief or pollen.

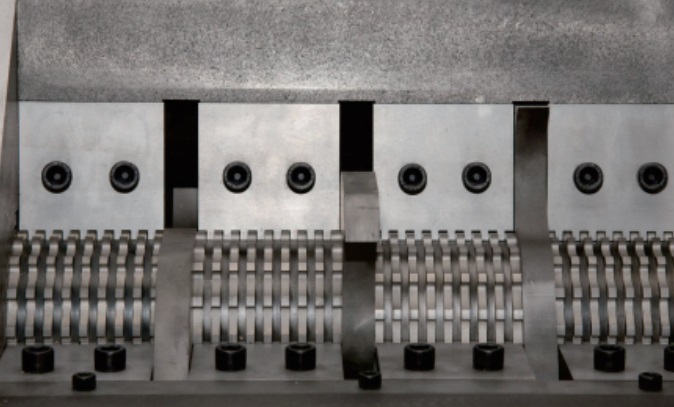

- Grinding teeth: Grinders feature sharp, pointed teeth that are used to break apart the cannabis material into smaller, more manageable pieces.

- Magnetic closure: Many grinders have a magnetic closure to keep the lid securely in place during use.

- Pollen screen: Some grinders have a fine mesh screen to collect kief or pollen, which can be used to enhance the cannabis experience.

- Portability: Some grinders are designed to be portable and discreet, making them easy to carry around in a pocket or bag.

Overall, the features of a cannabis grinder will depend on the specific type and model of grinder, as well as the user’s preferences and needs. Whether you’re looking for a small, portable grinder or a larger industrial grinder for processing large quantities of cannabis, there are many different options available to suit your needs.

| Business Type: | Manufacturer/Factory | Main Products: | Mill, grinder, granulator, mixer, Crushing Equipment |

| Number of Employees: | 100 | Year of Establishment: | 2014.05 |

| Production Capacity | 5000Set/Year | After-sales Service: | Technical Support; on-line teach lessons |

| R&D Capacity: | ODM, OEM | Annual Output Value: | US$5 Million – US$10 Million |

| No. of R&D Staff: | 5 | No. of Production Lines: | 6 |

LK Mixer is a professional manufacturer for grinder, mixer and pulverizer. These machines are widely used in pharmaceutical, cosmetic, health care products and chemical industries. Our main product including granulating machine, grinder, mixer, dryer, etc. All mechanical products in accordance with the China GMP design requirements. And also we have other certifications such as CE, UL for motors.

Business Philosophy

“Quality is the main policy of sales” and “integrity is the principle of success” are the business philosophy of our people. We carry out one-year warranty, lifelong maintenance service, with technical consultation, with material test machine and other services, and long-term supply of equipment. Welcome new and old customers to negotiate cooperation!

Certifications:

Electric Cabinet with UL Certification

Cyclone Processor and Motors:

Spare Parts:

Small Machine Packing:

Small machine packed with export fumigation-free wooden cases, goes with bulk shipment or in container.

When packing small machines for sea shipment, it is important to take measures to ensure that the machines are protected from damage during transit. Here are some general steps that a manufacturer may follow when packing small machines for sea shipment:

- Clean and dry the machine: Before packing, the machine should be thoroughly cleaned and dried to prevent any moisture or debris from causing damage during transit.

- Disassemble the machine: If possible, the machine should be disassembled into its component parts to reduce its overall size and make it easier to pack.

- Wrap the machine in protective material: The machine should be wrapped in a layer of protective material, such as bubble wrap or foam, to protect it from scratches and impact during transit.

- Place the machine in a sturdy box: The wrapped machine should then be placed in a sturdy box that is appropriate for the size and weight of the machine. The box should be made of durable material, such as corrugated cardboard or plywood, and should be able to withstand the rigors of sea transit.

- Add packing material: The box should be filled with packing material, such as packing peanuts or air pillows, to provide cushioning and prevent the machine from shifting during transit.

- Seal the box: The box should be securely sealed with high-quality packing tape to prevent it from opening during transit.

- Label the box: The box should be clearly labeled with the machine’s name, weight, and any other relevant information, as well as the destination address and contact information.

Overall, the goal is to pack the small machine in a way that will protect it from damage during transit and ensure that it arrives at its destination in good condition. It is important to follow proper packing procedures and use high-quality packing materials to minimize the risk of damage during sea shipment.

Large Machine Packing:

Packing a large machine for sea shipment can be a complex and challenging task. However, with careful planning and attention to detail, it is possible to pack a large machine for sea shipment in a way that will ensure that it arrives at its destination in good condition. Here are some general steps that a manufacturer may follow when packing up a large machine for sea shipment:

- Clean and prepare the machine: Before packing, the machine should be thoroughly cleaned and prepared. All fluids, such as oil or coolant, should be drained, and any loose or detachable parts should be removed.

- Disassemble the machine: If possible, the machine should be disassembled into its component parts to reduce its overall size and make it easier to pack. Each part should be carefully labeled and numbered to ensure that it can be easily reassembled at the destination.

- Protect delicate parts: Delicate or fragile parts should be wrapped in protective material, such as bubble wrap or foam, to protect them from damage during transit.

- Build a custom crate: A custom crate should be built around the machine to provide a secure and sturdy enclosure. The crate should be made of durable material, such as plywood, and should be designed to fit the machine snugly. The crate should also include braces or supports to prevent the machine from shifting during transit.

- Add cushioning material: The crate should be filled with cushioning material, such as packing peanuts or air pillows, to provide extra protection and prevent the machine from moving or shifting during transit.

- Securely fasten the machine: The machine should be securely fastened to the crate to prevent it from moving or shifting during transit. This may involve using straps, bolts, or other fasteners to hold the machine in place.

- Seal and label the crate: The crate should be securely sealed with high-quality packing tape, and should be clearly labeled with the machine’s name, weight, and any other relevant information. The destination address and contact information should also be clearly marked on the crate.

Overall, packing a large machine for sea shipment requires careful planning and attention to detail. It is important to use high-quality materials and follow proper packing procedures to ensure that the machine arrives at its destination in good condition. A professional packing and shipping company may be consulted to ensure that the machine is properly packed and prepared for sea shipment.

Customer Side Machine Groups Showcase Videos:

Dust Collector Shipment

Shipment – Packing Method

Two Large Industrial Grinder Ready to Ship

Domestic Shipment Show Case:

How to use a cannabis grinder?

Here are the steps to use a cannabis grinder:

- Break apart the cannabis buds: Before using the grinder, break apart the cannabis buds with your hands, separating the larger stems and leaves from the smaller flower buds.

- Load the grinder: Open the grinder and place the smaller flower buds into the grinder chamber. Do not overfill the grinder as this can cause it to jam.

- Grind the cannabis: Replace the lid on the grinder and twist it back and forth to grind the cannabis. Continue grinding until the desired consistency is achieved.

- Collect the ground cannabis: Once the cannabis is ground to the desired consistency, open the grinder and remove the ground cannabis. Use a small brush or scraper to collect any remaining cannabis from the grinder teeth.

- Use the ground cannabis: The ground cannabis can now be used in various ways, including rolling into a joint, packing into a pipe or vaporizer, or using for cooking or making edibles.

It is important to note that different types of grinders may have slightly different instructions for use. Always consult the manufacturer’s instructions for your specific grinder to ensure proper and safe use.

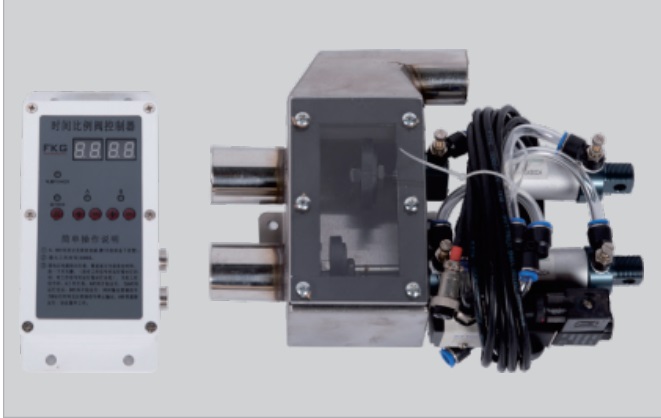

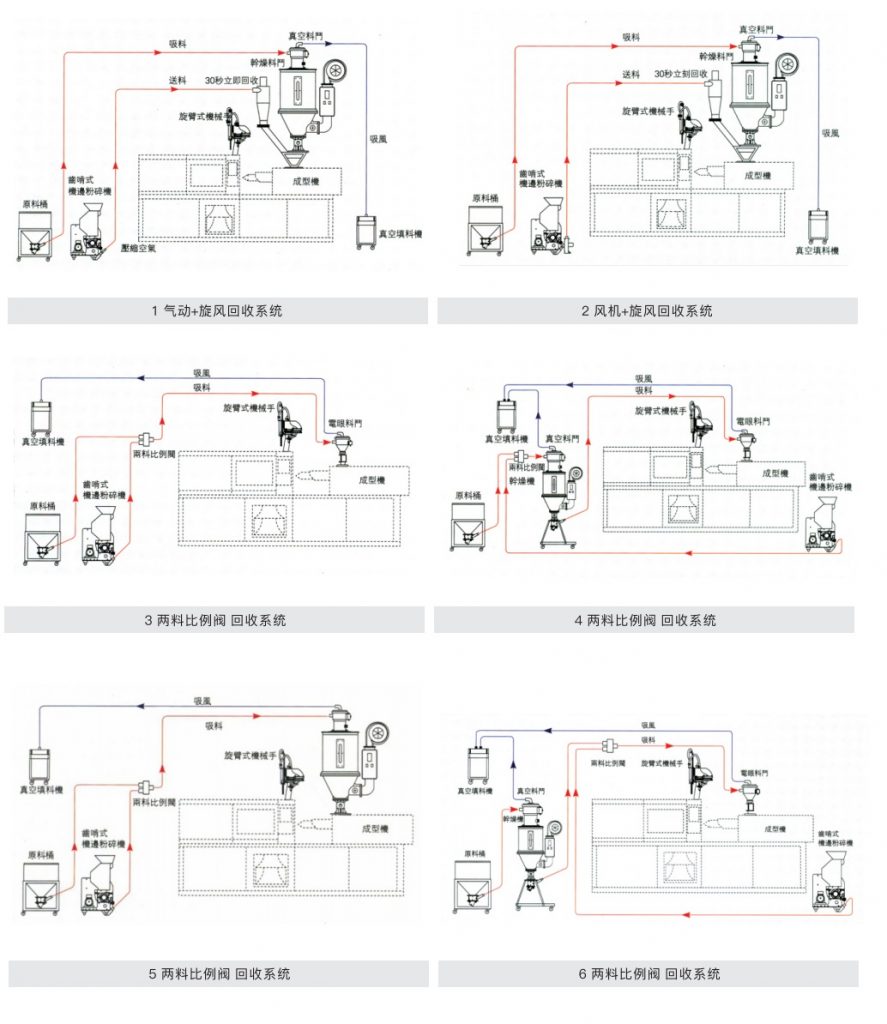

Installation Layout:

How to clean cannabis grinder?

Here are the steps to clean a cannabis grinder:

- Disassemble the grinder: Remove the lid and the chambers from the grinder to expose the teeth and interior surfaces.

- Scrape out any remaining material: Use a small brush, toothbrush, or scraper to remove any remaining cannabis particles or residue from the teeth and interior surfaces of the grinder. Be sure to collect any remaining material for later use.

- Soak the grinder in alcohol: Fill a container with isopropyl alcohol or another cleaning solution and place the disassembled grinder in the solution. Allow the grinder to soak for 20-30 minutes.

- Scrub the grinder: Using a small brush or toothbrush, scrub the teeth and interior surfaces of the grinder to remove any remaining residue or buildup.

- Rinse and dry: Rinse the grinder thoroughly with water to remove any remaining cleaning solution, then pat dry with a clean towel. Allow the grinder to air dry completely before reassembling and using again.

It is important to clean your cannabis grinder regularly to ensure that it functions properly and that the ground cannabis remains fresh and free from contaminants. How often you need to clean your grinder will depend on how frequently you use it and how sticky or oily the cannabis material is that you are grinding.

About LKMixer

LKMixer is a professional manufacturer for fertilizer production line, grinder, mixer and granulator, shredder. These machines are widely used in food, pharmaceutical, cosmetic, health care products and chemical industries. The Food materials like Peanut, mushroom, seeds, potato, bean, tobacco, salt, cannabis, tea, Sugar, corn, Coffee, rice, pepper, grain as so on. Grinders have many types such as Pulse Dust Grinder which suitable for zero pollution environment, Turbine Mill which is suitable for coffee bean, 12-120mesh all can meet, Ultrafine Grinding Mill covers 80-200mesh, and also Winnowing Dust Grinder or other grinding machines like SF Hammer. Welcome to contact us for details. Contact us for more information. Proposal, catalog, quotation. Mobile/WhatsApp: +86 18019763531 Tel: +86 21 66037855 Email: sales@lkmixer.com

Contact Us

SG Double Shaft Grinder for Industrial Seeds Grinder Youtube Video

FAQ(Click and See More)

What is the best method to grind cannabis?

The best method to grind cannabis depends on personal preference and the desired outcome. Here are some common methods for grinding cannabis:

Hand-grinding: This is the most basic and traditional method of grinding cannabis. It involves breaking the cannabis up into small pieces by hand, which can be time-consuming and can result in an inconsistent grind.

Scissors: Another manual method of grinding cannabis is to use a pair of scissors to cut the cannabis into small pieces. This method can be more precise than hand-grinding but can also be time-consuming.

Grinder: Using a grinder is a popular and efficient method of grinding cannabis. Grinders are designed to produce a consistent grind size and can be made of various materials, sizes, and shapes. Simply load the cannabis into the grinder and turn the lid to grind the material into small pieces.

Food processor: For larger quantities of cannabis, a food processor can be used to grind the material quickly and efficiently. This method can produce a finer grind than a traditional grinder, but may also result in more loss of trichomes and kief.

Overall, using a grinder is the most efficient and effective method for grinding cannabis. However, if you prefer a finer or more precise grind, a food processor or scissors may be a better option.

What is an industrial grinder?

An industrial grinder is a heavy-duty machine used to grind materials into smaller pieces or particles. These machines are commonly used in industrial settings such as factories, processing plants, and construction sites. They are designed to handle large volumes of materials quickly and efficiently, and are often equipped with powerful motors, large grinding wheels or blades, and sturdy frames to withstand the demands of heavy-duty use.

Industrial grinders can be used to process a wide range of materials including metal, wood, plastics, and more. They are commonly used in manufacturing and production processes to grind raw materials into smaller pieces or to prepare materials for further processing.

There are many different types of industrial grinders available, each designed for specific applications and materials. Some common types of industrial grinders include angle grinders, bench grinders, surface grinders, and cylindrical grinders. These machines can be operated manually or automatically, and can be powered by electricity, hydraulics, or other energy sources.