Industrial Salt Grinder

An industrial salt grinder is a specialized piece of equipment used in industries such as food processing, chemical manufacturing, and pharmaceutical production. These grinders are designed to handle large quantities of salt and are typically much larger than consumer-grade salt grinders. Industrial salt grinders may use a variety of grinding mechanisms, including rollers, blades, or hammer mills, depending on the application. They are often made of durable materials such as stainless steel or cast iron to withstand the rigors of heavy use. Industrial salt grinders may also be equipped with features such as adjustable settings, dust collection systems, and safety guards to ensure efficient and safe operation.

Super Grinder

- Feeding Granularity: <10mm;

- Powder Size: 80-320mesh

- Capacity: 10~2000kg/h according to different material

- Motor Power (KW): 13.37~119kw;

- Axis Rotating Speed(r/min):2000~6200;

- Dimension(mm):4200*1250*2700~8500*2800*4830.

- FOB Unit Price: 1 unit $ 12,000-48,923. More than 5 units: $10,800~44,031 Video

WF Universal Grinder – Hammer Mill

- Feeding Granularity: 10~15mm;

- Powder Size: 20-150mesh

- Capacity: 60-2000kg/h

- Motor Power (KW): 4-30kw;

- Axis Rotating Speed(r/min):2200~5300;

- Dimension(mm):500*500*1200~1800*1200*2500.

- FOB Unit Price: 1 unit $ 2,862~17,538. More than 5 units: $2,585~1,5785 Video

- Application: metal, Medicine, potato, bean, tea, rice, herb, pepper, grain, food, corn, Sugar

WF Dust Collector Grinder

- Feeding Granularity: <10mm~<20mm;

- Powder Size: 12~120 mesh;

- Capacity:100~2000kg/h(according different modes and raw materials);

- Motor Power (KW): 11.25~64.25kw;

- Axis Rotating Speed(r/min):1400~3800;

- FOB Unit Price: 1 unit $ 12,000-64,615. More than 5 units: $10,800~58,154. Video

- Application: Medicine, potato, bean, rice, herb, pepper, grain, food, corn, Sugar

WF Impuse Dust Grinder

- Powder Size: 12~200 mesh;

- Capacity: 10~1500kg/h(according to different mode and raw materials);

- Motor Power (KW): 5.5~22kw;

- Axis Rotating Speed(r/min):2200~5000;

- FOB Unit Price: 1 unit $ 6,462~8,492. More than 5 units: $5,815~7,643. Video

- Application: Medicine, potato, bean, rice, herb, pepper, grain, food, corn, Sugar

GFSJ High Speed Grinder

- Feeding Granularity: <10mm, <15mm;

- Powder Size: 5~80mm;

- Capacity: 10~600kg/h;

- Motor Power (KW): 3~18.5kw;

- Dimension(mm):1050*600*1600~1380*1200*1750.

- FOB Unit Price: 1 whole set unit $ 12,000~41,538. More than 5 whole set units: $10,800~37,385. Video

- Application: Medicine, potato, bean, tea, rice, herb, pepper, grain, food, corn, Sugar

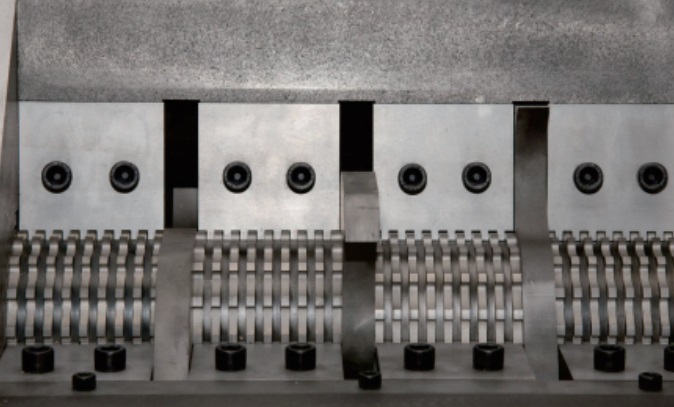

SG Double Shaft Grinder

- Feeding granule size: <5mm;

- Powder Size: 20~40 mesh;

- Capacity: 1~4000kg/h(according to different modes and raw materials);

- Motor Power (KW): 11~15kw;

- FOB Unit Price: 1 unit $ 6,646~10,154. More than 5 units: $5,982~9,138. Video

- Application: Medicine, potato, bean, rice, herb, pepper, grain, food, corn, Sugar

CSJ Coarse Crusher

WFJ Medicine Grinder – Hammer Mill

SF Hammer Mill

WFJ Turbo Grinder

- Feeding Size: 6~15mm;

- Crushing Fineness: 60-150mm;

- Motor Power (KW): 5.5~37kw;

- Axis Rotating Speed(r/min):2200~5500;

- Dimension(mm):550*600*1250~1250*1100*2280.

- FOB Unit Price: 1 whole set including dust collector unit $ 12,000~52,615. More than 5 whole set units: $10,800~47,354. Video

- Application: Medicine, potato, bean, rice, herb, pepper, grain, food, corn, Sugar

B Vacuum Mill

- Feeding Granularity: 10~15mm;

- Powder Size: 20~150 mesh;

- Capacity: 60-2000kg/h (according to mode and different raw material);

- Motor Power (KW): 4~30kw;

- Axis Rotating Speed(r/min):2200~5300;

- Dimension(mm):550*500*1200~1800*1200*2500.

- FOB Unit Price: 1 unit $ 3,692~5,538. More than 5 units: $3,323~4,985. Video

- Application: Medicine, potato, bean, rice, herb, pepper, grain, food, corn, Sugar

FL Airflow Pulverizer Supplier

- Feeding Granularity: <5mm, <10mm;

- Powder Size: 30~120 mesh;

- Capacity: 30~2200kg/h (according to mode and different raw material);

- Motor Power (KW): 4~22kw;

- Axis Rotating Speed(r/min):2200~4200;

- Dimension(mm):550*420*1400~1250*1100*2500.

- FOB Unit Price: 1 unit $ 3,415~4,800. More than 5 units: $3,065~4,320. Video

- Application: Medicine, potato, bean, rice, herb, pepper, grain, food, corn, Sugar

Electric salt and pepper grinder

I. Introduction

Background information on salt and its uses:

Salt is a mineral substance composed primarily of sodium chloride (NaCl), which is essential for human life. Salt has been used for thousands of years as a food preservative, flavor enhancer, and seasoning. It is also used in the manufacturing of various products such as soap, detergents, and fertilizers. In addition, salt is used in the chemical industry for the production of chlorine, soda ash, and other important chemicals.

In the food industry, salt is a crucial ingredient used to enhance the flavor and taste of different foods. It is used to cure meats, preserve fish, and pickle vegetables. Salt is also used in the baking industry to control yeast growth and in the production of cheese, butter, and other dairy products. In addition, salt is used as a seasoning in various cuisines around the world.

Salt is also an important commodity in the world economy, with many countries producing and exporting it. The largest producers of salt are China, the United States, India, and Germany. The global salt market is expected to continue growing due to increasing demand from the food and chemical industries, as well as from the growing population.

Importance of salt grinding in the industry:

Salt grinding is an important process in the industrial production of salt. It is the process of breaking down salt crystals into smaller particles to make them more suitable for use in different industries. The process of grinding salt is crucial for ensuring that the salt is of the desired particle size and uniformity, which is important for the proper functioning of various equipment and machinery.

In the food industry, the particle size of salt can affect the taste and texture of the food product. For instance, a larger particle size can result in a gritty texture, while a smaller particle size can dissolve quickly, leading to a saltier taste. Grinding salt to a specific particle size ensures consistency in flavor and texture of the food product, which is important for customer satisfaction.

In the chemical industry, salt is used in the production of different chemicals such as chlorine and soda ash. The particle size of salt is crucial for the proper functioning of the equipment used in the production process. For example, fine particles of salt can clog equipment, while larger particles can damage machinery. Therefore, grinding salt to a specific particle size is important for the efficient and safe production of chemicals.

In summary, salt grinding is an essential process in the industrial production of salt. It ensures that the salt is of the desired particle size and uniformity, which is important for the proper functioning of various equipment and machinery in different industries.

II. Literature Review

History and development of salt grinders:

Salt has been used for thousands of years as a food preservative and seasoning, and early civilizations used various methods to grind salt crystals. One of the earliest salt grinders was the mortar and pestle, which was used to grind salt crystals by hand. In ancient times, this method was used extensively in the Mediterranean region, and the mortar and pestle continued to be used in various cultures for centuries.

In the Middle Ages, salt was ground using a simple device called a quern. A quern was a hand-operated grinder made of two stones – a lower stationary stone called a quern stone and an upper stone called a handstone that was rotated by hand. The salt crystals were placed between the two stones and ground to a desired consistency.

In the 19th century, the invention of the steel roller mill revolutionized the salt grinding process. The roller mill was a mechanized device that used a series of steel rollers to grind salt crystals into a fine powder. This method allowed for the mass production of salt and made it more affordable and accessible to the masses.

In the 20th century, the salt grinding process continued to evolve with the introduction of new technologies such as the hammer mill and impact mill. These machines used high-speed rotating blades to grind salt crystals into smaller particles, which made the process more efficient and cost-effective.

Today, salt grinders come in various shapes and sizes, from simple handheld grinders to large industrial machines. They are used in different industries such as food, chemical, and pharmaceuticals, and are designed to grind salt crystals to a specific particle size and consistency.

Types of industrial salt grinders:

There are various types of industrial salt grinders available in the market, each with its own unique features and specifications. The most common types of industrial salt grinders are:

- Hammer Mills: Hammer mills are used to grind salt crystals by using high-speed rotating blades to break them down into smaller particles. They are often used in the food industry to grind salt for seasoning and flavoring, as well as in the chemical industry for the production of different chemicals.

- Roller Mills: Roller mills are similar to hammer mills, but they use a series of rollers instead of blades to grind salt crystals. They are often used in the production of table salt, as well as in the chemical industry for the production of various chemicals.

- Pin Mills: Pin mills use high-speed rotating pins to grind salt crystals into fine particles. They are often used in the food industry for grinding spices, herbs, and other dry ingredients.

- Impact Mills: Impact mills use high-speed rotating blades to grind salt crystals into fine particles. They are often used in the chemical industry for the production of different chemicals.

- Burr Mills: Burr mills use two revolving abrasive surfaces to grind salt crystals. They are often used in the food industry for grinding coffee beans, nuts, and spices.

- Grinders with Screens: Grinders with screens use a screen to separate the salt crystals into different particle sizes. They are often used in the food industry to ensure consistent particle size in spices and other dry ingredients.

In addition to these types of industrial salt grinders, there are also specialized grinders designed for specific industries such as the pharmaceutical industry.

Key features and specifications of industrial salt grinders:

Industrial salt grinders are designed to meet the specific needs of different industries, and they come with different features and specifications depending on their intended use. The key features and specifications of industrial salt grinders include:

- Grinding Capacity: The grinding capacity of an industrial salt grinder refers to the amount of salt it can grind in a given time. The grinding capacity varies depending on the type and size of the grinder.

- Particle Size: The particle size of salt crystals after grinding is an important specification for industrial salt grinders. Different industries require different particle sizes, and grinders are designed to produce specific particle sizes.dddddd

- Material of Construction: Industrial salt grinders are made of different materials, including stainless steel, carbon steel, and aluminum. The material of construction depends on the intended use and the type of salt being ground.

- Motor Power: The motor power of an industrial salt grinder determines its grinding capacity and efficiency. High-powered motors are required for grinding large volumes of salt quickly and efficiently.

- Grinding Mechanism: Industrial salt grinders use different grinding mechanisms such as hammer mills, roller mills, and pin mills. The grinding mechanism affects the particle size and consistency of the ground salt.

- Ease of Cleaning: Industrial salt grinders should be easy to clean and maintain to ensure optimal performance and longevity. Grinders that are difficult to clean may become clogged or contaminated, which can affect the quality of the ground salt.

- Safety Features: Industrial salt grinders should have safety features such as guards and emergency stop buttons to prevent accidents and injuries.

- Cost: The cost of industrial salt grinders varies depending on their features, specifications, and size. Higher-capacity and specialized grinders tend to be more expensive.

Overall, the key features and specifications of industrial salt grinders depend on the specific needs of the industry and the intended use of the grinder.

About LKMixer

LKMixer is a professional manufacturer for fertilizer production line, grinder, mixer and granulator, shredder. These machines are widely used in food, pharmaceutical, cosmetic, health care products and chemical industries. The Food materials like Peanut, mushroom, seeds, potato, bean, tobacco, salt, cannabis, tea, Sugar, corn, Coffee, rice, pepper, grain as so on. Grinders have many types such as Pulse Dust Grinder which suitable for zero pollution environment, Turbine Mill which is suitable for coffee bean, 12-120mesh all can meet, Ultrafine Grinding Mill covers 80-200mesh, and also Winnowing Dust Grinder or other grinding machines like SF Hammer. Welcome to contact us for details. Contact us for more information. Proposal, catalog, quotation. Mobile/WhatsApp: +86 18019763531 Tel: +86 21 66037855 Email: sales@lkmixer.com

Contact Us

| Business Type: | Manufacturer/Factory | Main Products: | Mill, grinder, granulator, mixer, Crushing Equipment |

| Number of Employees: | 100 | Year of Establishment: | 2014.05 |

| Production Capacity | 5000Set/Year | After-sales Service: | Technical Support; on-line teach lessons |

| R&D Capacity: | ODM, OEM | Annual Output Value: | US$5 Million – US$10 Million |

| No. of R&D Staff: | 5 | No. of Production Lines: | 6 |

LK Mixer is a professional manufacturer for grinder, mixer and pulverizer. These machines are widely used in pharmaceutical, cosmetic, health care products and chemical industries. Our main product including granulating machine, grinder, mixer, dryer, etc. All mechanical products in accordance with the China GMP design requirements. And also we have other certifications such as CE, UL for motors.

Business Philosophy

“Quality is the main policy of sales” and “integrity is the principle of success” are the business philosophy of our people. We carry out one-year warranty, lifelong maintenance service, with technical consultation, with material test machine and other services, and long-term supply of equipment. Welcome new and old customers to negotiate cooperation!

Certifications:

Electric Cabinet with UL Certification

Cyclone Processor and Motors:

Spare Parts:

Small Machine Packing:

Small machine packed with export fumigation-free wooden cases, goes with bulk shipment or in container.

When packing small machines for sea shipment, it is important to take measures to ensure that the machines are protected from damage during transit. Here are some general steps that a manufacturer may follow when packing small machines for sea shipment:

- Clean and dry the machine: Before packing, the machine should be thoroughly cleaned and dried to prevent any moisture or debris from causing damage during transit.

- Disassemble the machine: If possible, the machine should be disassembled into its component parts to reduce its overall size and make it easier to pack.

- Wrap the machine in protective material: The machine should be wrapped in a layer of protective material, such as bubble wrap or foam, to protect it from scratches and impact during transit.

- Place the machine in a sturdy box: The wrapped machine should then be placed in a sturdy box that is appropriate for the size and weight of the machine. The box should be made of durable material, such as corrugated cardboard or plywood, and should be able to withstand the rigors of sea transit.

- Add packing material: The box should be filled with packing material, such as packing peanuts or air pillows, to provide cushioning and prevent the machine from shifting during transit.

- Seal the box: The box should be securely sealed with high-quality packing tape to prevent it from opening during transit.

- Label the box: The box should be clearly labeled with the machine’s name, weight, and any other relevant information, as well as the destination address and contact information.

Overall, the goal is to pack the small machine in a way that will protect it from damage during transit and ensure that it arrives at its destination in good condition. It is important to follow proper packing procedures and use high-quality packing materials to minimize the risk of damage during sea shipment.

Large Machine Packing:

Packing a large machine for sea shipment can be a complex and challenging task. However, with careful planning and attention to detail, it is possible to pack a large machine for sea shipment in a way that will ensure that it arrives at its destination in good condition. Here are some general steps that a manufacturer may follow when packing up a large machine for sea shipment:

- Clean and prepare the machine: Before packing, the machine should be thoroughly cleaned and prepared. All fluids, such as oil or coolant, should be drained, and any loose or detachable parts should be removed.

- Disassemble the machine: If possible, the machine should be disassembled into its component parts to reduce its overall size and make it easier to pack. Each part should be carefully labeled and numbered to ensure that it can be easily reassembled at the destination.

- Protect delicate parts: Delicate or fragile parts should be wrapped in protective material, such as bubble wrap or foam, to protect them from damage during transit.

- Build a custom crate: A custom crate should be built around the machine to provide a secure and sturdy enclosure. The crate should be made of durable material, such as plywood, and should be designed to fit the machine snugly. The crate should also include braces or supports to prevent the machine from shifting during transit.

- Add cushioning material: The crate should be filled with cushioning material, such as packing peanuts or air pillows, to provide extra protection and prevent the machine from moving or shifting during transit.

- Securely fasten the machine: The machine should be securely fastened to the crate to prevent it from moving or shifting during transit. This may involve using straps, bolts, or other fasteners to hold the machine in place.

- Seal and label the crate: The crate should be securely sealed with high-quality packing tape, and should be clearly labeled with the machine’s name, weight, and any other relevant information. The destination address and contact information should also be clearly marked on the crate.

Overall, packing a large machine for sea shipment requires careful planning and attention to detail. It is important to use high-quality materials and follow proper packing procedures to ensure that the machine arrives at its destination in good condition. A professional packing and shipping company may be consulted to ensure that the machine is properly packed and prepared for sea shipment.

Customer Side Machine Groups Showcase Videos:

Dust Collector Shipment

Shipment – Packing Method

Two Large Industrial Grinder Ready to Ship

Domestic Shipment Show Case:

How to use a cannabis grinder?

Here are the steps to use a cannabis grinder:

- Break apart the cannabis buds: Before using the grinder, break apart the cannabis buds with your hands, separating the larger stems and leaves from the smaller flower buds.

- Load the grinder: Open the grinder and place the smaller flower buds into the grinder chamber. Do not overfill the grinder as this can cause it to jam.

- Grind the cannabis: Replace the lid on the grinder and twist it back and forth to grind the cannabis. Continue grinding until the desired consistency is achieved.

- Collect the ground cannabis: Once the cannabis is ground to the desired consistency, open the grinder and remove the ground cannabis. Use a small brush or scraper to collect any remaining cannabis from the grinder teeth.

- Use the ground cannabis: The ground cannabis can now be used in various ways, including rolling into a joint, packing into a pipe or vaporizer, or using for cooking or making edibles.

It is important to note that different types of grinders may have slightly different instructions for use. Always consult the manufacturer’s instructions for your specific grinder to ensure proper and safe use.

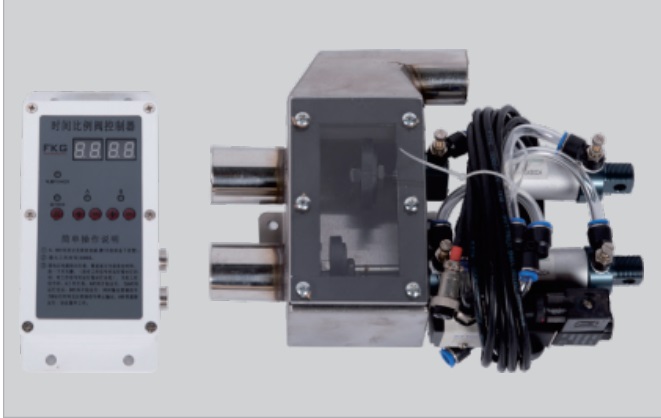

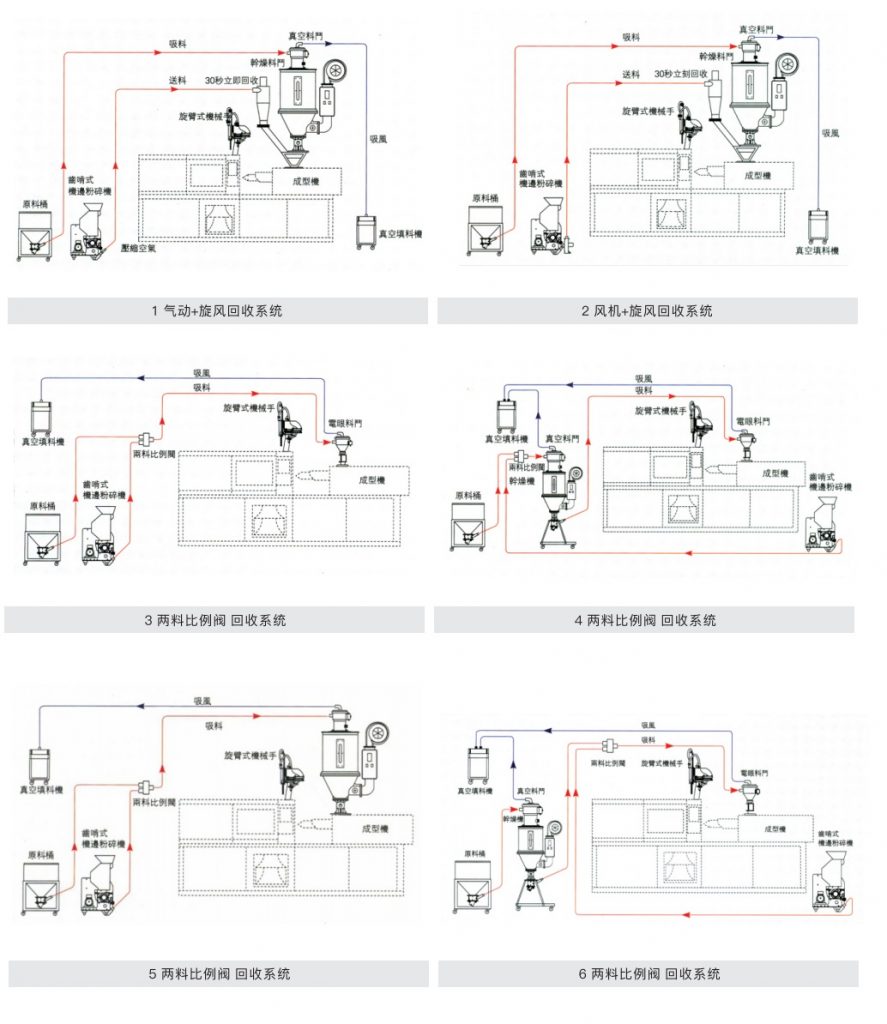

Installation Layout:

SG Double Shaft Grinder for Industrial Seeds Grinder Youtube Video (See More)

FAQ(Click and See More)

What is the best salt grinder?

Here are some general guidelines on what to look for when choosing a salt grinder.

Material: Salt grinders are made of various materials such as ceramic, stainless steel, and acrylic. Ceramic grinders are known for their durability and ability to retain sharpness, while stainless steel grinders are rust-resistant and easy to clean. Acrylic grinders are often lightweight and affordable, but may not last as long as other materials.

Adjustable settings: Look for a salt grinder with adjustable settings, allowing you to grind your salt to your desired coarseness. This feature will give you greater control over the texture of your salt, and therefore, the flavor of your food.

Capacity: Consider how much salt you plan on grinding at once and choose a grinder with a capacity that suits your needs. Some grinders have larger capacities, making them suitable for regular use in a commercial kitchen, while smaller ones are ideal for home use.

Design: Choose a salt grinder that fits your personal style and complements your kitchen décor. Some grinders have a sleek and modern design, while others have a more traditional look.

Price: Salt grinders are available at various price points, so consider your budget when choosing one. Keep in mind that higher-priced grinders may be made of better quality materials and have more features, but you can still find a quality grinder within your budget.

Overall, the best salt grinder for you will depend on your personal preferences and needs. Consider the factors mentioned above to find a grinder that suits your requirements.

What is the difference between a salt grinder and a salt mill?

Both salt grinders and salt mills are used for grinding salt, but there are some differences between them:

Salt grinders usually have a simple design, with a single grinder mechanism that grinds the salt into coarse or fine particles. They may have a manual or electric operation, and often come with adjustable settings for the coarseness of the grind.

Salt mills are more complex and may have multiple grinding mechanisms that can be adjusted to produce different levels of fineness. They may also have additional features, such as a cap to keep the salt fresh and a tray to catch any stray salt particles.

In summary, a salt grinder is a simpler tool that is good for everyday use, while a salt mill is a more advanced tool that is often used by professional chefs or serious home cooks who require precise control over the texture of their salt.

What is the difference between a salt and pepper mill grinder?

A salt and pepper mill grinder may look similar, but there are a few key differences between the two:

Grinding mechanism: The grinding mechanism of a pepper mill is typically made of steel or ceramic, while a salt grinder may have a stainless steel or nylon mechanism. This is because salt can corrode steel over time, so it’s important to use a non-corrosive material for the grinding mechanism.

Texture of the grind: Pepper mills are designed to produce a range of grind sizes, from very fine to coarse. This is because pepper is often used as a seasoning and may require different textures depending on the dish. Salt mills, on the other hand, are typically designed to produce a coarser grind, as the texture of the salt itself is important in seasoning.

Size and shape of the salt and pepper chambers: Some salt and pepper mills have differently shaped chambers or different sizes for salt and pepper. This helps prevent confusion between the two and makes it easier to fill and clean the mills.

In summary, the main differences between a salt and pepper mill grinder are the materials used for the grinding mechanism, the texture of the grind, and the size and shape of the chambers.

What is salt for grinder called?

Salt for grinders is commonly called “coarse salt” or “rock salt”. This type of salt has larger crystals than table salt, which makes it ideal for use in salt grinders or mills. It’s also often used for seasoning meat or fish, as the larger crystals help to penetrate the surface and add flavor. Coarse salt can usually be found in most grocery stores and is available in both iodized and non-iodized versions.