CSJ Primary crushers

- Price: USD 3,323 CSJ-200

- Production Capacity:10-2200kg/h

- Feeding Size:≤ 100

- Crushing fineness:0.5-20mm

- Spindle speed:960 r/min

- Motor power: 2.2~30kw

- Machine Weight:120-800kg

We Can Customize Motor, electric cabinet, with Certification. Design layout according to your request.

Primary crushers video Youtube

Electric Cabinet with UL Certification

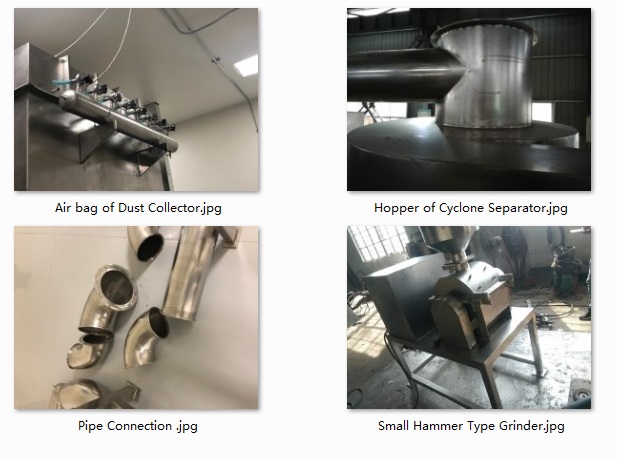

Cyclone Processor and Motors:

Spare Parts:

Coarse Crusher for Sale:

Plastic Crusher Machine for Sale:

Plastic shredders are machines that can break various types of plastic waste into smaller pieces for easy recycling. They are also known as plastic crushers, shredders. LKMixer are a manufacturer of plastic crusher machine, We offer various types of plastic crusher and plastic granulator for plastic recycling.

CSJ600 Coarse Crusher Machine Design

High Coarse Crusher Technical Parameters:

| Type | Production capacity(kg/h) | Main speed(r/min) | Feed size(mm) | Crush size(mm) | Power(kw) | Weight(kg) | Overall dimensions L × W × H(mm) |

| 80 | 10-80 | ≤ 100 | 0.5-20 | 960 | 2.2 | 120 | 600 * 450 * 860 |

| 200 | 80-300 | ≤ 100 | 0.5-20 | 960 | 4 | 200 | 900 *600 * 1440 |

| 300 | 100-800 | ≤ 100 | 0.5-20 | 960 | 7.5 | 300 | 900 * 700 * 1440 |

| 400 | 200-1000 | ≤ 100 | 0.5-20 | 960 | 15 | 380 | 900*800*1440 |

| 600 | 500-1500 | ≤ 100 | 0.5-20 | 960 | 18.5 | 500 | 1000*900*1440 |

| 800 | 600-2200 | ≤ 100 | 0.5-20 | 960 | 30 | 800 | 1250*1100*1650 |

Trade Capacity

| International Commercial Terms(Incoterms): | FOB, CIF, CFR | Terms of Payment: | LC, T/T, PayPal, Western Union |

| Average Lead Time | 60 working days | Main Markets | North America, South America, Europe, Southeast Asia/ Mideast, East Asia(Japan/ South Korea), Australia, Domestic |

| Nearest Port: | Ningbo Port; Shanghai Port | Factory Address: | JiangSu, China |

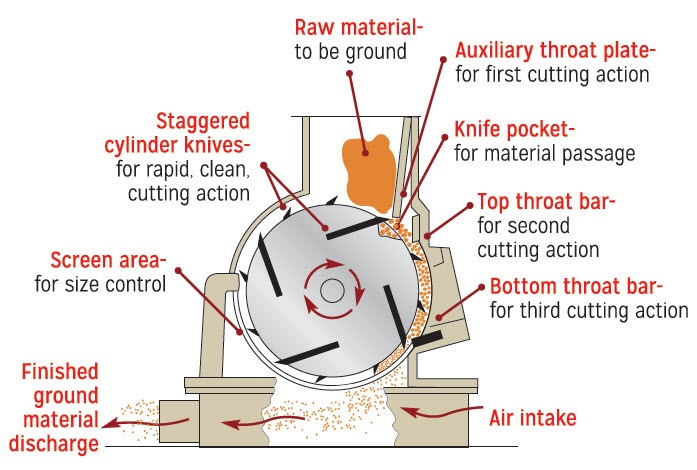

Primary Crusher Introduction and Working Principle:

Primary Crusher machinery and equipment are widely used in mining, smelting, building materials, roads, railways, water conservancy and chemical industry and many other sectors. Commonly used crushing machines are jaw crusher, impact crusher, wind mill, hammer crusher, impact crusher, roll crusher, compound crusher, sand making machine, etc. It has the characteristics of large crushing ratio, uniform product particle size, simple structure, reliable work, easy maintenance, and economic operating costs. The PF-I series impact crusher can handle materials with side length below 100 ~ 500 mm, and its compressive strength can reach up to 350 mpa. It has the advantages of large crushing ratio and cubic particles after crushing. PF-II series impact crusher, used for crushing medium hard materials, such as limestone crushing in cement plants, has the advantages of large production capacity and small discharge particle size.

Types of Primary Crusher:

Jaw Crusher:

Jaw crusher (also known as tiger mouth) appeared in 1858, with a large crushing ratio, uniform particle size, simple structure, reliable work, easy maintenance, economic operating costs and other characteristics, is the first choice for crushing equipment, so it is widely used in mining, smelting, building materials, roads, railways, water conservancy and chemical industry and many other sectors.

This series of crusher is most suitable for crushing various soft and hard ores with compressive strength not higher than 320MPa (mpa), and the maximum bulk degree of the crushed material shall not be greater than that specified in the technical parameter table.

- The crushing chamber is deep and has no dead zone, which improves the feeding capacity and output;

- Its crushing ratio is large, and the product particle size is uniform;

- Gasket type discharge port adjustment device, reliable and convenient, large adjustment range, increase the flexibility of the equipment;

- The lubrication system is safe and reliable, the parts are easy to replace, and the maintenance workload is small;

- Simple structure, reliable work, low operating costs.

- Equipment energy saving: single-machine energy saving 15% ~ 30%, system energy saving more than double;

- The adjustment range of discharge port is large, which can meet the requirements of different users;

- Low noise, less dust.

Impact primary crusher:

Commonly known as sand making machine, is the use of the United States Barmack company’s famous “stone” crusher principle and technology, combined with the actual situation of sand production at home and abroad to develop and develop with the international advanced level of high energy and low consumption equipment, its performance in a variety of ore fine breaking equipment plays an irreplaceable role, is the most effective, practical and reliable gravel machine. The crusher is an ideal production equipment for construction sand, road sand, bedding material, asphalt concrete and cement concrete aggregate, so it is widely used.

Widely used in metal and non-metallic ores, cement, refractory materials, abrasives, glass raw materials, building aggregates, artificial sand and a variety of metallurgical slag crushing and rough grinding operations, especially for hard, especially hard and abrasive materials such as silicon carbide, emery, sintered aluminum vanadium, magnesia, more than other types of crusher has advantages. Used together with hydraulic protection jaw break, it can handle all kinds of metallurgical slag. It is suitable for building sand and road sand.

In terms of its working principle, the impact crusher is simply the principle of stone-beating. Let the stone collide with the stone accelerated by the impeller in the process of natural fall, so as to achieve the purpose of crushing, and the stone accelerated to form a vortex when it collides with the stone naturally falling, and breaks twice in the process of return, so the wear of the machine counterattack plate during the operation is very little!

The impact crusher has the advantages of simple structure, large crushing ratio, low energy consumption, high output, light weight, and cubic shape of the finished product after crushing, and is widely used in various ore crushing, railway, highway, energy, cement, chemical industry, construction and other industries.

Cone Crusher:

It has simple structure, stable performance, easy to fail, convenient maintenance, large production capacity, high efficiency, high quality, and has a variety of cavity shape medium and fine crushing, double safety control hydraulic and lubrication system, so it is widely used in metal mining, metallurgy industry, chemical industry, construction industry, cement industry and sand and gravel industry.

Compound crusher:

The compound crusher is a new type of highly efficient fine crushing equipment with melting hammer breaking and counter breaking in one

Large production capacity, high crushing efficiency, large crushing ratio, small amount of abrasion, low energy consumption, good sealing, smooth operation, easy maintenance and other outstanding advantages. When the equipment is used in building materials enterprises to break limestone, coal, coal gangue and cement clinker, it can significantly reduce the grinding particle size and increase the mill output, and is an ideal energy-saving crushing equipment.

Hammer crusher:

Hammer crusher has the characteristics of large crushing ratio, high production capacity, uniform product particle size, etc. The crusher is one of the main equipment for fine crushed limestone, coal or other brittle materials below medium hardness in the industrial sectors of metallurgy, building materials, chemical industry and hydropower.

Single-stage crusher:

Single-stage crusher has the advantages of large crushing ratio, fine discharge particle size, simplified process, low operating cost, and is widely used in cement, ceramics, glass, artificial sand and stone, coal, non-metal mines and new green building materials industries.

Roller crusher:

Roller crusher is suitable for crushing medium hardness materials in cement, chemical, electric power, metallurgy, building materials, refractories and other industrial sectors, such as limestone, slag, coke, coal and other materials in the crushing, fine crushing operation.

Primary crusher mining

Jaw crusher production case

Jaw crusher feed size: 120-1500mm, production capacity: 1-2200t/h It is the most widely used equipment in the mine, mainly used for coarse stone crushing, can be broken into smaller particle size of the following equipment. The equipment has the advantages of simple structure, cheap price, convenient maintenance and low operating cost, and can be used in gravel, sand making, grinding, mineral processing and other industries.

Impact crusher feed size: ≤1300mm, processing capacity: 30-800t/h. This is a medium crushing equipment, the discharge particles are very good, can improve the price of finished aggregate, the price of counter crushing is cheaper than the cone crushing of the same medium crushing equipment, but the wear resistance will be slightly worse. Widely used in all kinds of ore crushing, railway, highway, energy, cement, chemical, construction and other industries.

Cone broken feed size: 65-300mm production capacity: 12-1000t/h The overall manufacturing process is relatively advanced, set P in one LC remote control technology, reduce on-site personnel, improve safety indicators, in addition, cone broken parts have strong wear resistance, large output range, generally used in large production lines. Widely used in sand and gravel field, concrete sand, dry powder mortar, construction waste, machine sand, power plant desulfurization and other industries.

In addition to the above equipment, there are hammer crusher, roll crusher, compound crusher, fine crusher, mobile crusher and so on.

Primary rock crusher

Primary crusher, referred to as coarse crusher, is widely used in mining, metallurgy, building materials, highway, railway, hydraulic, chemical and other industries. Primary crusher has the advantages of crushing ratio, uniform mechanical particle size, simple structure, simple work, inspection and maintenance, and economic operating cost. What are the primary crushing equipment? What are its advantages? Next, I will make a brief analysis (for reference only).

Difference between primary and secondary crusher

There are many kinds of crusher, some are used for rough breaking and some are used for fine breaking, different kinds of crusher action and performance are also different, the following is a simple analysis of their respective characteristics.

Fine breaking is a type of jaw crusher. Usually as a secondary crushing instead of the impact crusher, the E type fine crusher referred to as fine breaking is the most commonly used crushing equipment in the crushing series, mainly used for the compressive strength of not more than 320 mpa of various materials, with reliable, easy maintenance, economic operating costs and other characteristics.

Coarse crusher: also known as coarse crusher, coarse crusher is widely used in mining, smelting, building materials, road and railway, water conservancy and chemical industry and many other sectors, crushing compressive strength does not exceed 320 mpa of various materials.

Heavy hammer breaking, that is, heavy hammer crusher, alias is also called hammer king. Suitable for mining, cement, coal, metallurgy heavy hammer breaking: building materials, highways, burning and other departments of medium hardness and brittle materials for fine crushing. The difference between the heavy hammer crusher and the hammer crusher: the hammer head of the heavy hammer can be rotated 360 degrees around the hammer shaft, and the length of the hammer head is not the same, and the material of the hammer head is not the same.

The coarse crusher (coarse break) is placed in the first break, the fine crusher (fine break) is placed in the second break, the coarse crusher feed port is larger than the fine break, and the working efficiency and life are similar, because the working principle is the same. Are the use of low speed, high stability of the working principle.

Ultrafine mill is a fine powder and ultrafine powder grinding processing equipment, this equipment is mainly suitable for medium and low hardness, humidity is less than 6%, Mohs hardness below 9 non-flammable and explosive non-metallic materials.

Feature of Primary crushers:

A coarse crusher is a type of equipment used in industries such as mining, agriculture, and construction to crush large materials into smaller pieces for further processing. Here are some common features of a coarse crusher:

- Large feed opening: A coarse crusher usually has a large feed opening to accommodate larger materials.

- Strong and durable construction: The construction of a coarse crusher is usually robust and durable to withstand the heavy impact and force of the crushing process.

- High crushing ratio: A coarse crusher typically has a high crushing ratio, which means that it can crush large materials into smaller pieces efficiently.

- Simple structure: A coarse crusher typically has a simple structure, which makes it easy to operate and maintain.

- Adjustable discharge size: Some coarse crushers have an adjustable discharge size, which allows for more precise control over the size of the crushed material.

- High capacity: A coarse crusher can typically process large amounts of material quickly and efficiently, making it ideal for industries that require high throughput rates.

- Coarse Crusher is suitable for many industries such as pharmaceutical , chemical , food and others. It is quite widely used nowadays;

- It is a pretreatment machine before procedure of fine grinding equipment; this pretreatment procedure can help upgrade the capacity and increase the output for production;

- This series machine normally is not influenced by the material viscosity, hardness, softness, and fiber and other restrictions, any material can play better crushing effect;

Overall, a coarse crusher is a powerful tool that is essential for many industries, particularly those that require the processing of large materials.

| Business Type: | Manufacturer/Factory | Main Products: | Mill, grinder, granulator, mixer, Crushing Equipment |

| Number of Employees: | 100 | Year of Establishment: | 2014.05 |

| Production Capacity | 5000Set/Year | After-sales Service: | Technical Support; on-line teach lessons |

| R&D Capacity: | ODM, OEM | Annual Output Value: | US$5 Million – US$10 Million |

| No. of R&D Staff: | 5 | No. of Production Lines: | 6 |

LK Mixer is a professional manufacturer for grinder, mixer and pulverizer. These machines are widely used in pharmaceutical, cosmetic, health care products and chemical industries. Our main product including granulating machine, grinder, mixer, dryer, etc. All mechanical products in accordance with the China GMP design requirements. And also we have other certifications such as CE, UL for motors.

Business Philosophy

“Quality is the main policy of sales” and “integrity is the principle of success” are the business philosophy of our people. We carry out one-year warranty, lifelong maintenance service, with technical consultation, with material test machine and other services, and long-term supply of equipment. Welcome new and old customers to negotiate cooperation!

Certifications:

Small Machine Packing:

Small machine packed with export fumigation-free wooden cases, goes with bulk shipment or in container.

Large Machine Packing:

Customer Side Machine Groups Showcase Videos:

Dust Collector Shipment

Shipment – Packing Method

Two Large Industrial Grinder Ready to Ship

Domestic Shipment Show Case:

Operation Instruction

General Provisions

The first reprint machine, shredder driver must be trained, to achieve the “three understanding” (understand the structure, understand the performance, understand the principle), “four” (will use, will maintain, will maintain, will deal with the fault), after the training test qualified, obtain a certificate, quasi post operation.

Article 2 Cooperate closely with the scraper conveying driver of the working face and the belt conveyor driver of the transportation lane, make unified signal contact, and start and stop in order. When large lump coal and gangue are accumulated and spilled at the feed port of the crusher, the operation of the scraper conveyor should be stopped. If there are large lumps of coal, gangue cannot enter the broken plane or there are metal objects, it must be shut down for treatment.

Preparation Work

- 1. Tools: wrench, pliers, screwdriver, hammer, spade, etc.

- 2, necessary spare parts: all kinds of short chain, chain link, bolts, nuts, crusher insurance dowel, etc.;

- 3. Lubricating oil and turbine oil

Treatment of inspection

- 1, motor, reducer, hydraulic coupling, head, tail and other parts of the connection must be complete, intact, tight. Reducer, hydraulic shaft joint should have no oil leakage, oil leakage, oil quantity should be appropriate.

- 2, signal must be sensitive and reliable, no signal is not allowed to start. Make sure the spray sprinklers are in good condition.

- 3. Power cables and operation lines must be hung neatly without being squeezed;

- 4, the coal, gangue, sundries near the nose and the coal dust of the motor and reducer must be cleaned;

- 5, face scraper conveyor head and reprint machine tail lap to be suitable;

- 6. The scraper chain plate is of moderate importance, and the scraper and screws must be fully fastened;

- 7, reprinting machine walking trolley must be stable and reliable;

- 8. When the machine is partly turned on, the operation of each part should have no abnormal sound, and the scraper, chain and connecting ring should have no torsion, twist and bend deformation;

- 9. The roadway support at the shredder and shredder must be intact and firm.

- 10, the safety protection net and protection device of the crusher, to ensure that no deformation no failure, safe and reliable;

- 11. The roadway support of the reprinting machine and the shredder must be intact and firm.

Precautions

Trial run

- 1. Switch on the power grid switch;

- 2. Manually press the click button for the trial run of the machine;

- 3. Start and idling for 1 ~2 weeks;

- 4. Joint operation of reprinting machine and shredder;

- 5. Check that there is no abnormality and send a startup signal.

- 6, the operation of the machinery and motor should be no vibration, sound and humidity should be normal, the bearing temperature should not exceed 75℃, motor temperature should not exceed the nameplate provisions.

- 7. The chain tightness of the reprinting machine must be consistent. Under the condition of full load, the chain tightness is not allowed to exceed the length of two chain rings.

- 8. After the fusible plug or fried piece of the joint of the reprinting machine is damaged, wood or other materials shall not be used instead.

- 9. The safety device of the protective net of the crusher should be kept in good condition, and should be checked frequently in the working process. If there is any damage, it should be stopped immediately.

- 10, reprinting machine tail protection and other safety devices must be ensured intact.

- 11, transfer and transfer machine.

- (1) Clean the floating coal and gangue in the tail, on both sides of the fuselage and under the bridge;

- (2) Protect cables, water pipes, oil pipes, and hang them neatly;

- (3) Check the roadway support, and push the reprinting machine under the condition of ensuring safety;

- (4) The walking trolley and the tail frame of the belt conveyor should have good contact, do not run off, and have good lap after moving, prevent large plastics from hurting the tape, and ensure smooth coal flow;

- (5) After the transfer machine, the nose and tail should be kept flat, straight and stable, and the jack live rod should be recovered.

Operation Attention

- 1, plastic crusher and power unit to install firmly. If need long-term fixed operation, plastic crusher should be fixed on the cement base; If the plastic crusher is needed for mobile operation, the unit should be installed on a base made of Angle iron, and ensure that the power machine (diesel engine or motor) and the belt pulley groove of the plastic crusher are in the same rotary plane. 2. After the installation of the plastic crusher, the fasteners of all parts should be checked and tightened if they are loose. At the same time to check the belt tightness is appropriate.

- 3. Before starting the plastic crusher, first rotate the rotor by hand to check whether the jaw, hammer and rotor are flexible and reliable, whether there is collision in the crushing room, whether the rotating direction of the rotor is consistent with the direction indicated by the arrow of the machine, and whether the lubrication of the power machine and plastic crusher is good.

- 4, do not casually replace the belt pulley, in case the speed is too high resulting in the explosion of the crushing chamber, or the speed is too low affecting the working efficiency of the crusher.

- 5. After starting the plastic crusher, it should be kept idling for 2~3min, and then feeding after there is no abnormal phenomenon.

- 6, the work should always pay attention to the operation of the plastic crusher, first of all, the feeding should be uniform, to prevent blocking the crushing chamber; Second, don’t overwork for a long time. If there is vibration, noise, bearing and body temperature is too high, spraying material and other phenomena, should immediately stop the machine for inspection, troubleshooting before continuing to work.

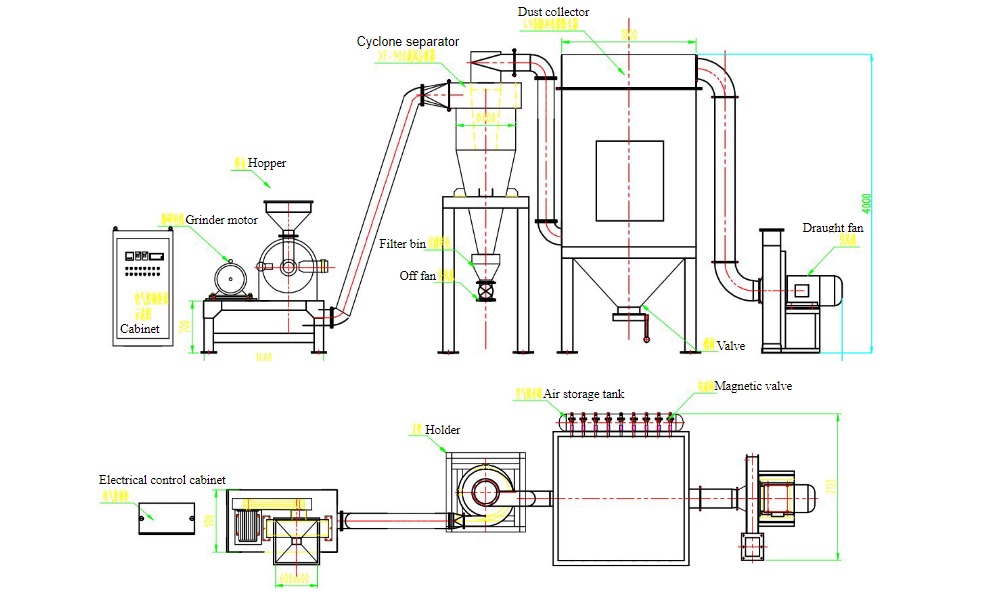

Installation Layout:

Crusher machine manufacturers

- Working Time: Mon~Fri 8:00~17:00

- Mobile/WhatsApp: +86 18019763531

- Tel: +86 21 66037855

LKMixer is a professional manufacturer for Crusher machine, grinder, mixer and granulator, shredder. These machines are widely used in food, pharmaceutical, cosmetic, health care products and chemical industries. The Food materials like Peanut, mushroom, seeds, potato, bean, tobacco, salt, cannabis, tea, Sugar, corn, Coffee, rice, pepper, grain as so on. Grinders have many types such as Pulse Dust Grinder which suitable for zero pollution environment, Turbine Mill which is suitable for coffee bean, 12-120mesh all can meet, Ultrafine Grinding Mill covers 80-200mesh, and also Winnowing Dust Grinder or other grinding machines like SF Hammer. Welcome to contact us for details.

Contact Us

Primary crusher for sale:

What is coarse crusher?

A coarse crusher is a type of grinding equipment that is used to crush large materials into smaller pieces. Coarse crushers are typically used in industries such as mining, construction, and recycling, where large rocks, debris, or other materials need to be broken down into smaller pieces for further processing or disposal.

Coarse crushers typically use mechanical force to break down materials, such as through the use of a jaw crusher or a cone crusher. These types of crushers rely on a fixed or moving jaw or cone to apply pressure to the material and break it down into smaller pieces.

Coarse crushers are designed to handle large, hard materials that may be difficult to process using other types of grinding equipment. They can be used for a variety of applications, including crushing concrete and asphalt, breaking down rocks and minerals, and reducing the size of construction debris.

Overall, coarse crushers are an important type of grinding equipment used in many industries to process large materials and prepare them for further processing or disposal.

What is the difference between grinder and crusher?

Grinders and crushers are both types of grinding equipment used in various industries, but there are some key differences between the two:

Purpose: Grinders are typically used to grind and refine materials into a more uniform size and shape, while crushers are used to crush large materials into smaller pieces.

Types of materials: Grinders are often used to process materials that are dry or have a low moisture content, while crushers are used to process materials that are moist or sticky or dry.

Method of operation: Grinders typically use a rotating wheel or drum to grind materials, while crushers use pressure to crush materials.

Size of output: Grinders can produce very fine particles, while crushers typically produce larger pieces of material that may require additional processing.

Applications: Grinders are commonly used in industries such as agriculture, food processing, and metalworking, while crushers are used in industries such as mining, construction, and recycling.

Overall, the main difference between grinders and crushers is that grinders are used to refine materials into a more uniform size and shape, while crushers are used to crush large materials into smaller pieces. The choice of equipment used will depend on the specific needs of the application and the type of materials being processed.

What is the difference between a mill and a crusher?

A mill and a crusher are both types of grinding equipment used to process materials, but there are some key differences between the two:

Purpose: Mills are typically used to grind and refine materials into a more uniform size and shape, while crushers are used to crush large materials into smaller pieces.

Types of materials: Mills are often used to process materials that are dry or have a low moisture content, while crushers are used to process materials that are moist or sticky.

Method of operation: Mills typically use a rotating wheel or drum to grind materials, while crushers use pressure to crush materials.

Size of output: Mills can produce very fine particles, while crushers typically produce larger pieces of material that may require additional processing.

Applications: Mills are commonly used in industries such as agriculture, food processing, and metalworking, while crushers are used in industries such as mining, construction, and recycling.

Overall, the main difference between mills and crushers is that mills are used to refine materials into a more uniform size and shape, while crushers are used to crush large materials into smaller pieces. The choice of equipment used will depend on the specific needs of the application and the type of materials being processed.

Auxiliary Machine for Sale:

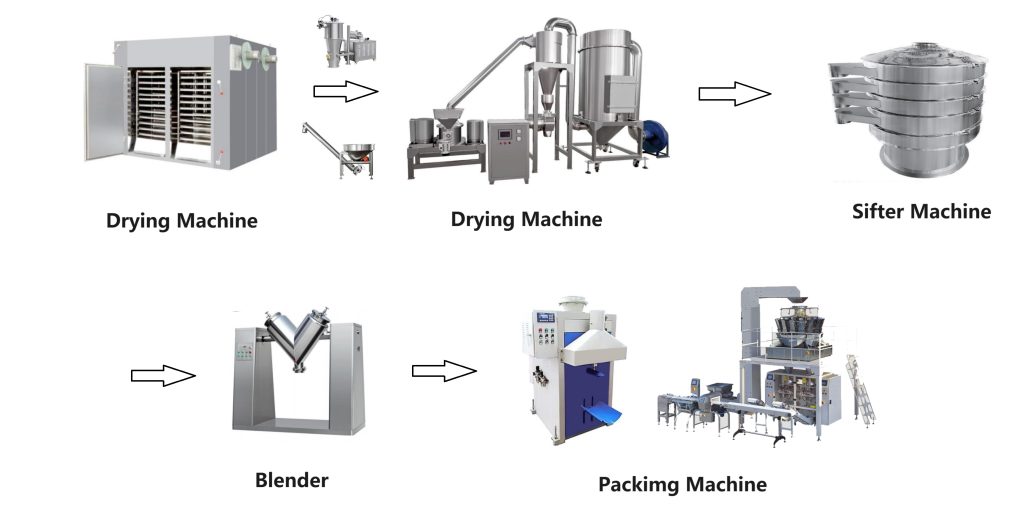

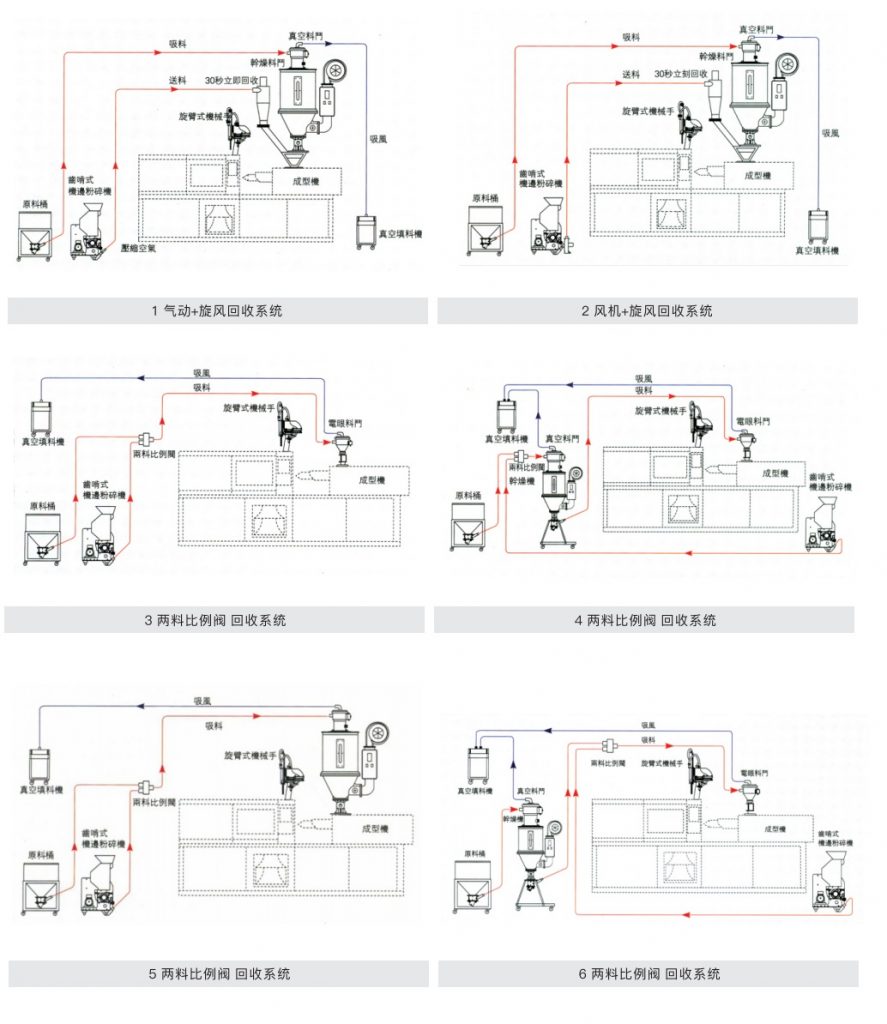

Production Line Customization Solution:

LINKER is a manufacturer of grinding and mixing machine. We can customize whole automatic production line according to customer special request. According to your special material, capacity requirement and motor and electric cabinet certification requirement, we can customize semi-auto or fully automatic production line for our customer. Please contact us for detail proposal and quotation.

Drying Machine + Grinding Machine + Sifter Machine + Mixing Machine + Packing Machine: