Plastic Recycling Shredders Machines

Plastic Recycling -medium speed machine side grinder

- Application: Suitable for spot recycle of scrape products of small plastic bottles, containers, pellicle plastics, sheets from injection molding machines and extrusion parts, tailored to an extremely wide range of applications.

- Voltage: 380V (3 phases)

- Dimension: 660*650*880 ~750*520*1420 ( 6 types for your choice)

- Weight: 105~210kg;

- Motor Power:1.1~2.2kw;

- Price: $ 743-1,179.

What is Plastic Recycling Shredders Machines:

This machine can be installed beside machine to collect and crush the waste plastics immediately;

Plastic Recycling Shredders Machines (plastic mill) means to crush all kinds of plastic and rubber, such as plastic profiles, tubes, rods, threads, films, waste rubber products. Granular material can be directly extruded as raw material.

This kind of machine adopts alloy steel blade, long life; At the same time, the machine adopts separation design, easy maintenance and cleaning, and has a double-layer structure, equipped with sound insulation material, low noise, knife shaft seat after a strict balance test, machine base and equipped with four wheels, easy to move.

Plastic Recycling Shredders Machines Classifications:

Plastic crusher in the injection molding industry, also known as: plastic crusher. [1] There are three main categories:

(1) Hard plastic shredder, this machine is suitable for crushing all kinds of small and medium-sized plastic plates:

1, ABS, PE, PP board and other boards crushing recovery;

2, for the plate material crushing and unique design of rectangular feeding port, easy to put the strip plate crushing, improve work efficiency. Optional suction fan, storage bucket composed of plate crushing recovery system can give full play to recovery efficiency;

3, the use of sealed bearings, so that the bearing rotation for a long time to keep good; Cutter design is reasonable, the product granule uniform; Knife block heat shrinkable processing, beautiful and generous shape design;

(2) Strong plastic shredder:

1, sheet knife structure between claw knife, flat knife, suitable for breaking ordinary sheet, pipe, profile, plate and packaging materials and other plastic products;

2, general plastic crusher, using sealed bearing, so that the bearing rotation for a long time to keep good;

3, the cutter design is reasonable, the alloy steel blade, the product into uniform grain, the knife block heat shrink processing, and after a strict balance test, the shape design is beautiful and generous;

(3) Plastic pipe plastic crusher:

1, suitable for crushing all kinds of small and medium-sized plastic pipe, such as PE, PVC pipe, silicon core pipe and other pipe crushing recovery;

2, for the pipe material crushing and unique design of the round pipe feeding port, easy to crush the strip pipe, improve the work efficiency. Optional suction fan, storage bucket composed of pipe crushing recovery system can give full play to recovery efficiency;

3, the use of sealed bearings so that the bearing rotation for a long time to maintain good; Reasonable cutter design can make the product granule uniform; The heat shrinkable treatment of knife holder makes the shape design beautiful and generous.

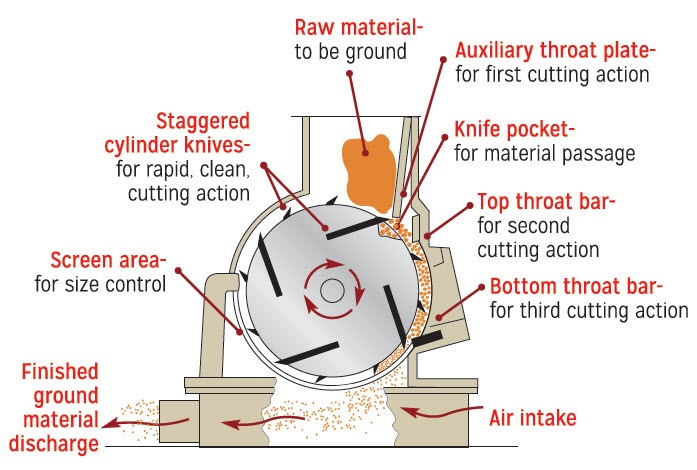

Industrial Plastic Grinder Machine:

Ampere of Motors Customization for Pepper Mill:

| KW | HP | Ampere |

| 75kw | 100HP | 135A |

| 55kw | 75HP | 99A |

| 30kw | 40HP | 54A |

| 22kw | 30HP | 39A |

| 2.2kw | 3HP | 3.9A |

| 1.5kw | 2HP | 2.7A |

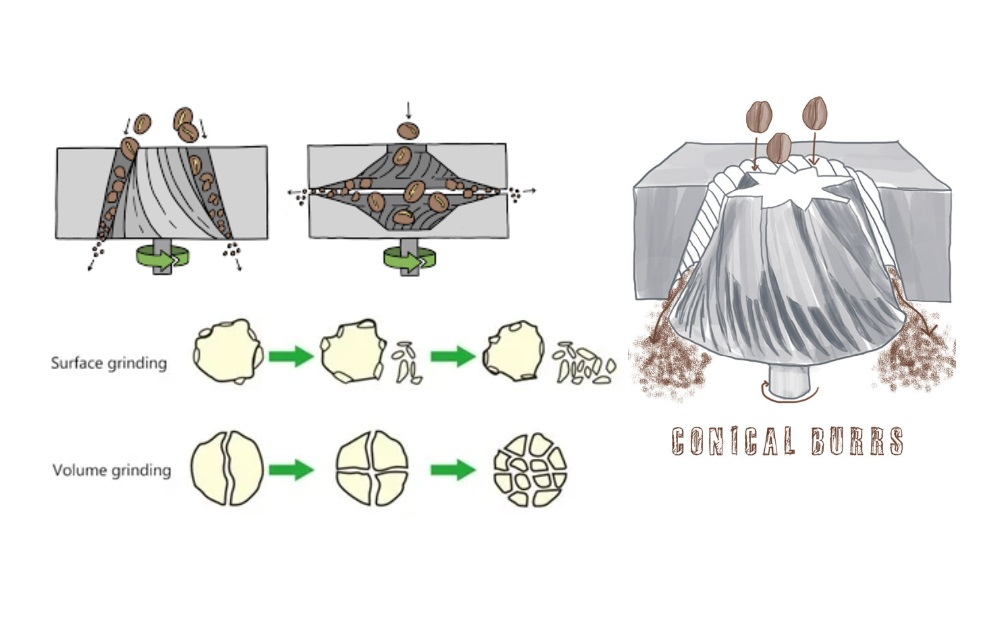

Coffee Grinder Youtube Video (WFJ Turbine Type Grinder is Suitable for baked Coffee Bean)

Coffee Grinder Youtube Video (Hammer Type is NOT suitable for baked Coffee Bean, because it’s too oil.)

About LKMixer

LKMixer is a professional manufacturer for fertilizer production line, grinder, mixer and granulator, shredder. These machines are widely used in food, pharmaceutical, cosmetic, health care products and chemical industries. The Food materials like Peanut, mushroom, seeds, potato, bean, tobacco, salt, cannabis, tea, Sugar, corn, Coffee, rice, pepper, grain as so on. Grinders have many types such as Pulse Dust Grinder which suitable for zero pollution environment, Turbine Mill which is suitable for coffee bean, 12-120mesh all can meet, Ultrafine Grinding Mill covers 80-200mesh, and also Winnowing Dust Grinder or other grinding machines like SF Hammer. Welcome to contact us for details. Contact us for more information. Proposal, catalog, quotation. Mobile/WhatsApp: +86 18019763531 Tel: +86 21 66037855 Email: sales@lkmixer.com

Contact Us

FAQ(Click and See More)

How to choose the right models?

– Choose small or large ? Calculate your current customer capacity request, this is to get a estimate capacity needs. To think about you only for small quantity use or large quantity. Do you want to expand your customer base so that need to expand your capacity in near future? If yes, you can order larger machine instead of small machine. If not, smaller one is more suitable for you.

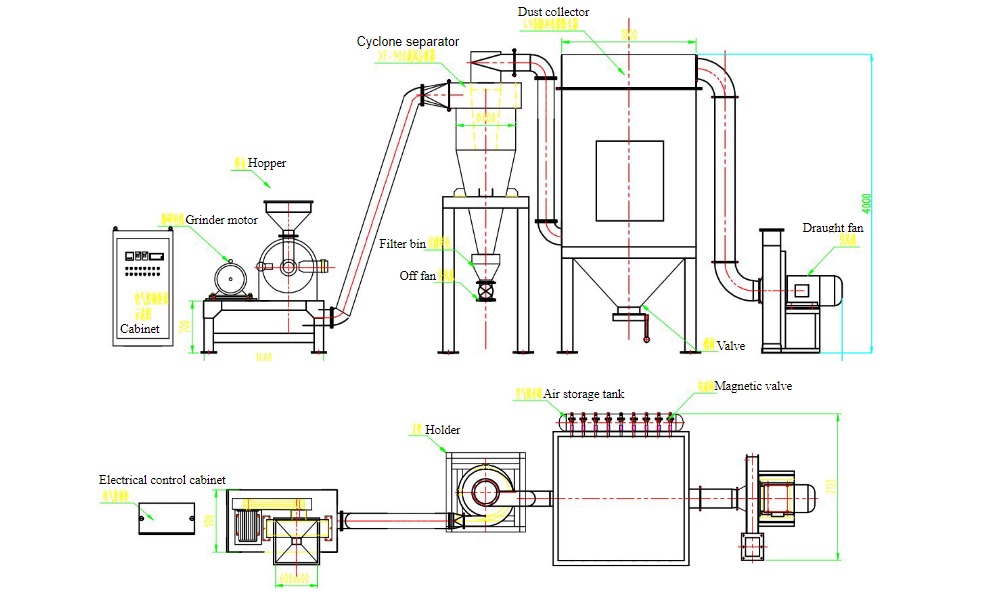

– Choose single or whole group? Single machine is cheaper and easy to move from here to there, space location are also easy. Whole group machine including material feeder, main machine, cyclone sperator and rotary valve. Whole group machine not easy to move cause of link of each portions. But whole group also advantages such as easy to dust collect, save manpower. Think about clearly what you want, we would know which is right to choose.

– If you think about your customers and volume, you’ll be off to a good start in knowing what you need from your grinder.

What machine will shred plastic?

There are several machines that can shred plastic, depending on the type and volume of plastic being processed. Here are some common machines used for plastic shredding:

Single-shaft shredder: This is a simple shredder that uses a single shaft with rotary blades to shred plastic into smaller pieces. It is suitable for small to medium-sized plastic waste.

Dual-shaft shredder: This machine has two shafts with rotary blades that work together to shred plastic into smaller pieces. It is suitable for larger plastic waste, such as pipes and profiles.

Granulators: These machines use a cutting system with a series of rotating blades to chop plastic into small pieces. They are typically used for processing plastic waste that has been pre-shredded.

Grinders: These machines use rotating blades to grind plastic into a fine powder or granulate. They are commonly used for processing plastic film, bottles, and other plastic waste.

Hammer mills: These machines use a series of hammers to break up plastic waste into smaller pieces. They are typically used for processing harder, thicker plastic waste.

Pulverizers: These machines use high-speed rotating blades to pulverize plastic into a fine powder. They are typically used for processing plastic film, sheets, and other thin plastic waste.

The specific machine used for shredding plastic will depend on the type and volume of plastic waste being processed, as well as other factors such as the desired end product and the available budget.

What can I use to grind plastic?

It is not recommended to grind plastic using common household appliances or tools, as they are not designed to handle this type of material and could become damaged or pose a safety hazard.

If you need to grind plastic, it is recommended to use specialized equipment designed for this purpose, such as plastic shredders, grinders, or pulverizers. These machines use specially designed blades and cutting mechanisms to efficiently and safely shred plastic into small pieces or powder.

If you only need to grind a small amount of plastic, you could try using a mortar and pestle or a coffee grinder, but keep in mind that these tools may not be effective for larger quantities of plastic, and could also damage the equipment.

If you are unsure about how to grind plastic, it is best to consult with a professional or a manufacturer of plastic grinding equipment for guidance on the best approach to take.

What is the fastest way to break down plastic?

Plastic is a synthetic polymer that is designed to be durable and long-lasting, which means that it can take a very long time to break down naturally. However, there are several ways to accelerate the process of breaking down plastic, including:

Mechanical recycling: This involves shredding or grinding plastic into small pieces, which can then be melted down and used to make new products.

Chemical recycling: This involves using chemical processes to break down the plastic into its constituent molecules, which can then be used to make new plastic products.

Biodegradation: Some types of plastic are designed to be biodegradable, which means they can be broken down by bacteria and other microorganisms in the environment. However, this process can take a long time and requires specific conditions to be effective.

Pyrolysis: This involves heating plastic in the absence of oxygen, which breaks it down into its constituent components, including oil and gas. These components can then be used to make new products or as fuel.

Photodegradation: This involves exposing plastic to sunlight, which can break down the plastic over time. However, this process can take a long time and may not be practical for large amounts of plastic.

It is important to note that while these methods can help break down plastic more quickly, they each have their own advantages and disadvantages, and may not be suitable for all types of plastic waste. Proper disposal and recycling of plastic is important to reduce the environmental impact of plastic waste.